Material lifting device of roadway stacker

A lifting device and stacker technology, applied in storage devices, transportation and packaging, etc., can solve the problems of falling, high equipment, affecting the working efficiency of roadway stackers, etc., and achieve the effect of improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

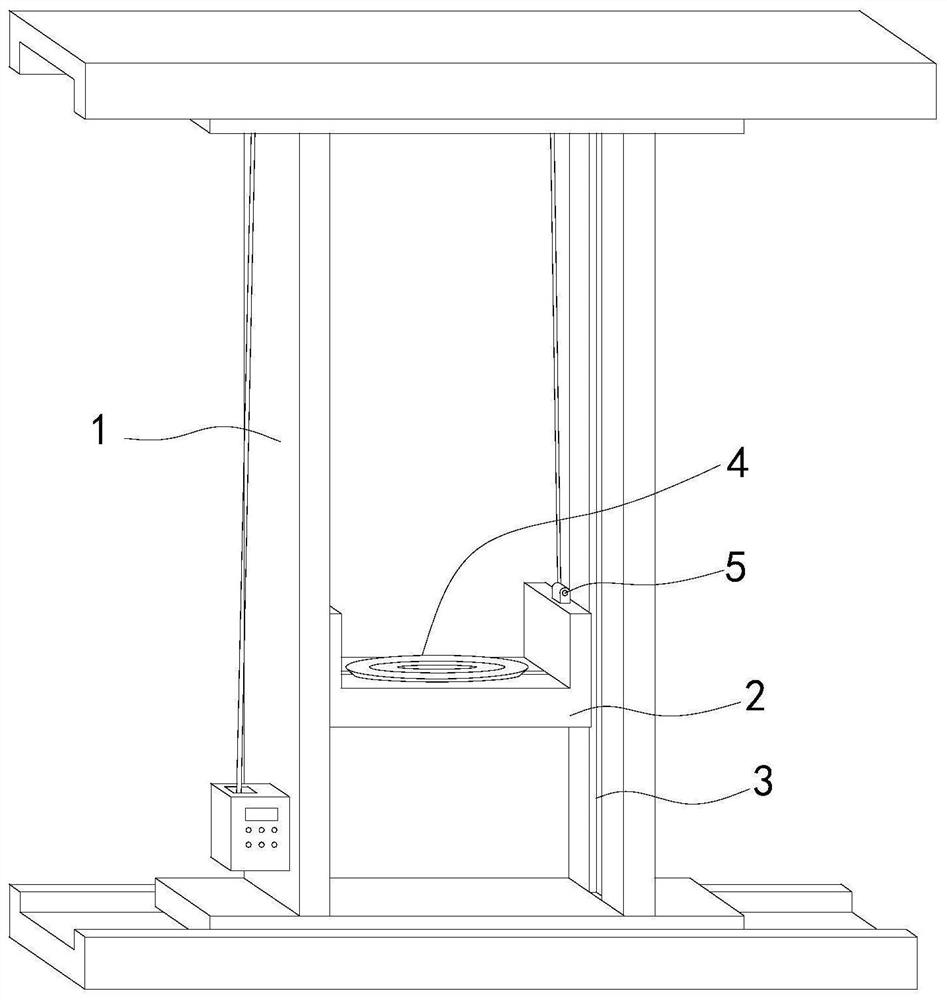

[0026] see Figures 1 to 8 , a schematic diagram of the planar structure and a schematic diagram of the three-dimensional structure of a material lifting device of a roadway stacker.

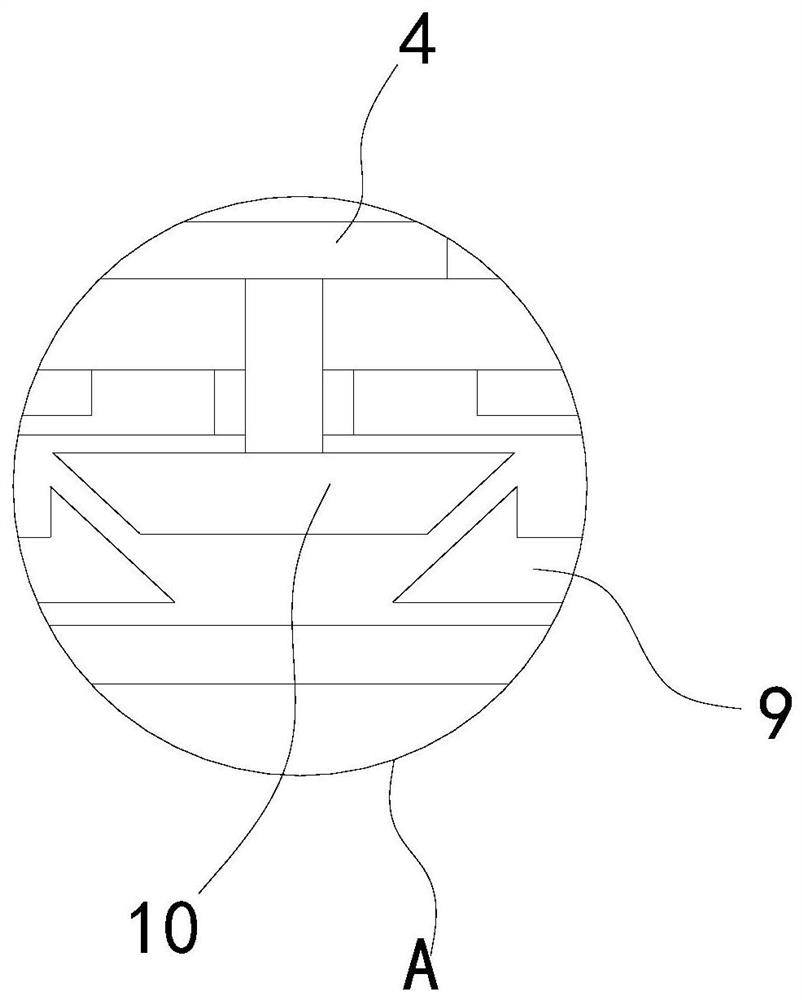

[0027] A material lifting device for a roadway stacker, comprising a device support plate 1, a loading platform 2, a limit groove 3 is provided on the inner side of the equipment support plate 1, an ejector plate 9 is movable installed inside the lower end of the loading platform 2, and the loading platform 2. A fixing device 4 is movably installed on the upper end, and a through groove 6 is opened on the inner side of the fixing device 4, and a transmission rotating rod 8 is movably installed on both sides inside the stage 2.

[0028] In the specific implementation, the lower part of the middle end of the fixing device 4 is fixedly installed with a lower pressing block 10, which is set in the shape of a circular platform, so that when the goods are placed on the upper end of the fixing device 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com