Polystyrene vacuum automatic packaging molding machine

A polystyrene, automatic packaging technology, applied in vacuum/special atmosphere packaging, packaging, transportation packaging, etc., can solve the problems of long operation time and low efficiency, and achieve the effect of saving time and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

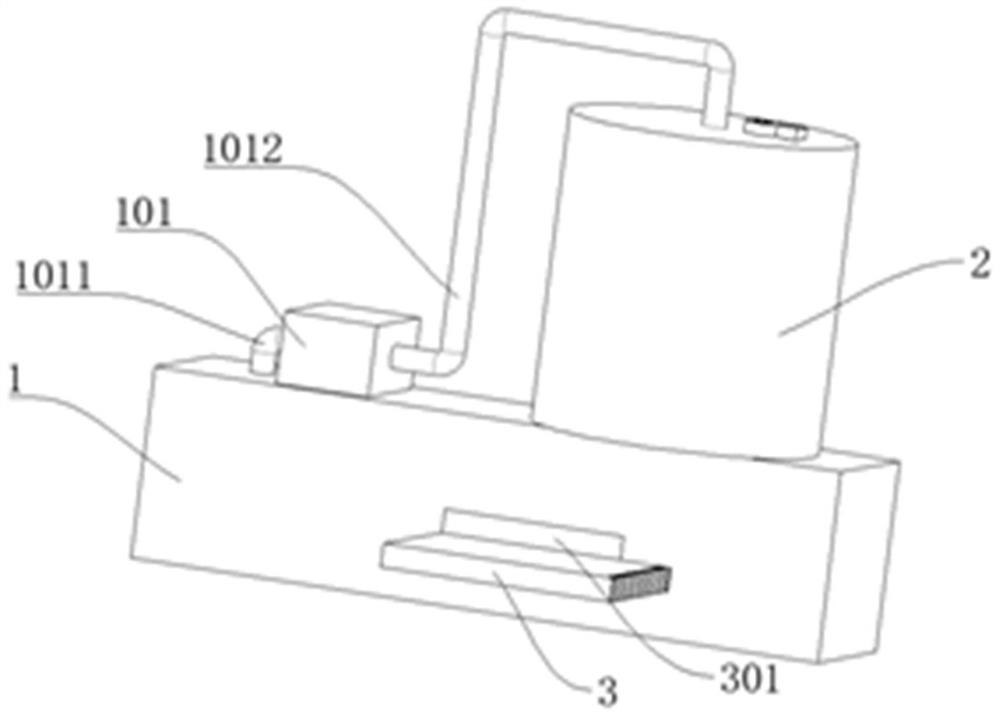

[0032] refer to Figure 1-7 , a polystyrene vacuum automatic packaging molding machine, comprising a box body 1, an air pump 101, and a heat press sealing machine 4011, the box body 1 is provided with a vacuum chamber 1001, the air pump 101 and the box body 1 are connected through a first connecting pipe 1011, and Including the gas cylinder 2, the gas cylinder 2 and the suction pump 101 are connected through the second connecting pipe 1012, the piston plate 4 is slidably connected in the gas cylinder 2, the lower end of the piston plate 4 is fixedly connected with the connecting plate 401, and the connecting plate 401 is slidably connected to the gas cylinder 2, the box body 1, the heat press sealing machine 4011 is connected to the bottom end of the connection plate 401, and the transmission and placement plate 3 is slidably connected to the box body 1, and the transmission and placement plate 3 is connected to the connection plate 401.

[0033] When the user is in use, by cl...

Embodiment 2

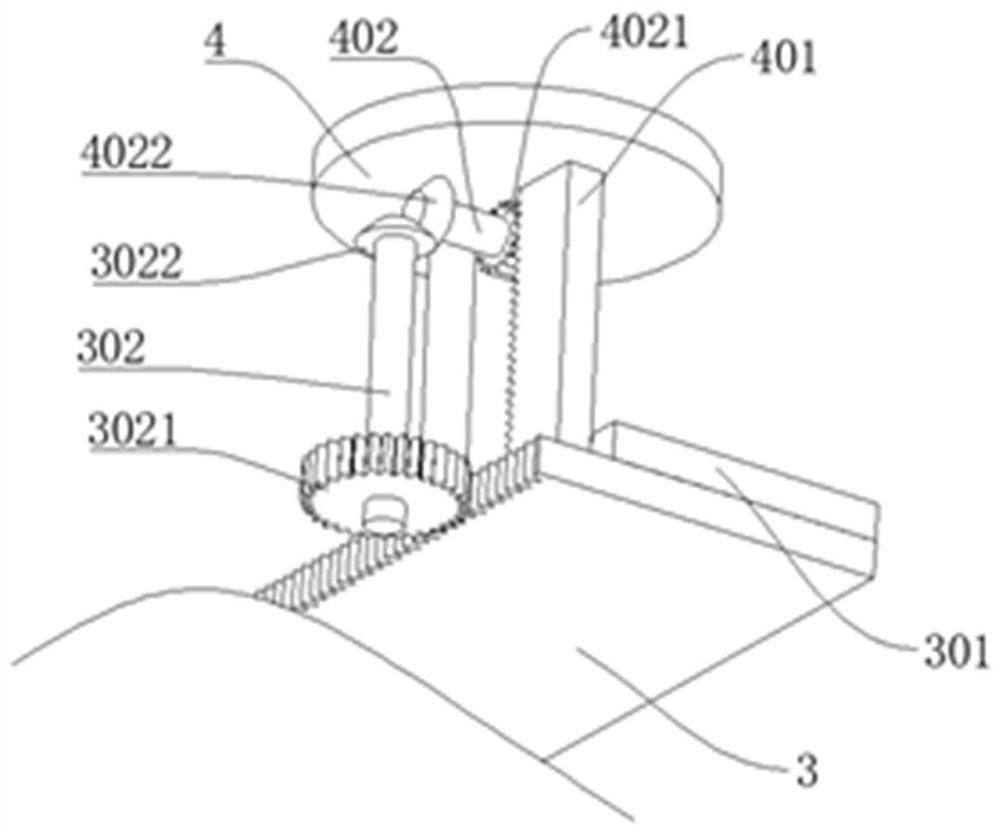

[0035] refer to Figure 1-7, which is basically the same as that of Embodiment 1, furthermore, the gas cylinder 2 is fixedly connected with a support plate 4033, the support plate 4033 is rotatably connected with a second rotating shaft 402, and the two ends of the second rotating shaft 402 are respectively connected with a driving gear 4021, a second rotating shaft Two helical gears 4022, the casing 1 is rotatably connected with a first rotating shaft 302, and the two ends of the first rotating shaft 302 are respectively connected with a first gear 3021 and a first helical gear 3022, and the first helical gear 3022 and the second helical gear 4022 are in phase meshing, the connecting plate 401 is provided with a tooth groove matching the driving gear 4021, and the transmission placement plate 3 is provided with a tooth groove matching the first gear 3021, the driving gear 4021 adopts a one-way gear, and the driving gear 4021 is clockwise When moving, the second rotating shaft...

Embodiment 3

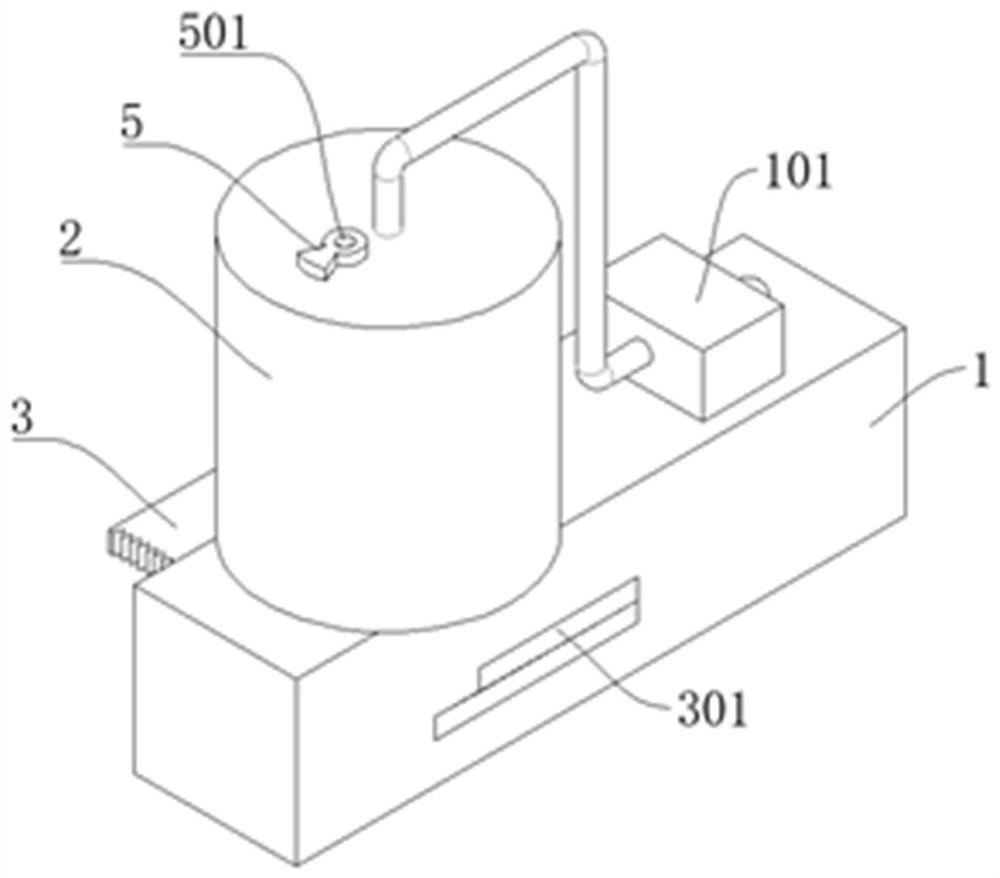

[0038] refer to Figure 1-7 , is basically the same as that of Embodiment 1, furthermore, the top of the gas cylinder 2 is provided with an exhaust port 2001, and the gas cylinder 2 is provided with an exhaust switch 5 that matches the exhaust port 2001, and the exhaust switch 5 is rotatably connected with a mobile Column 501, piston plate 4 is fixedly connected with telescopic rod 502, one end of moving column 501 is slidably connected in telescoping rod 502, threaded bar is provided on moving post 501, and threaded bar matching threaded bar is provided on exhaust switch 5 Groove, piston plate 4 upper ends are fixedly connected with spring 201, and the other end of spring 201 is fixedly connected with inflator 2 inner wall, and the junction of exhaust switch 5 and exhaust port 2001 is provided with rubber pad.

[0039] When the user is in use, when the piston plate 4 moves down, it will drive the telescopic rod 502 to move down, and the moving column 501 is slidably connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com