A clamp-replaceable two-jaw manipulator

A technology of manipulators and fixtures, which is applied in the field of manipulators, can solve problems such as danger and low efficiency, and achieve the effects of reducing economic losses, improving work performance, and suitable clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

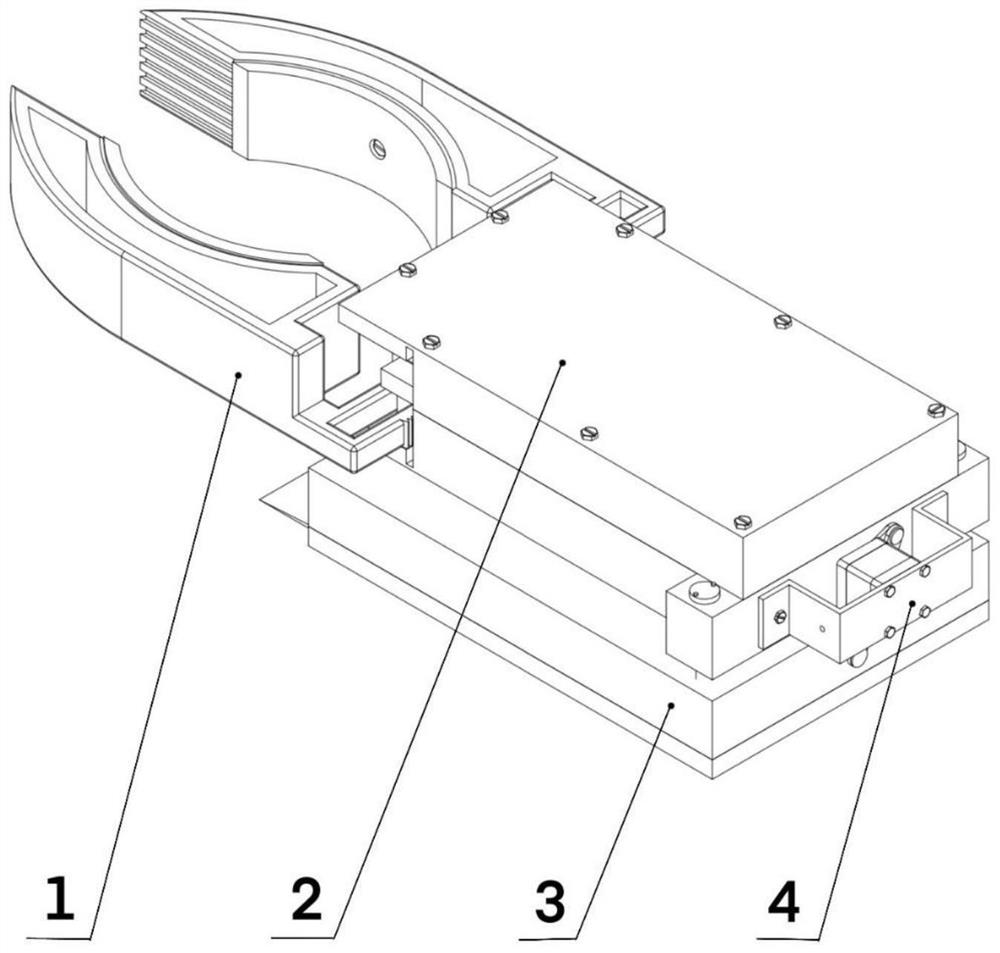

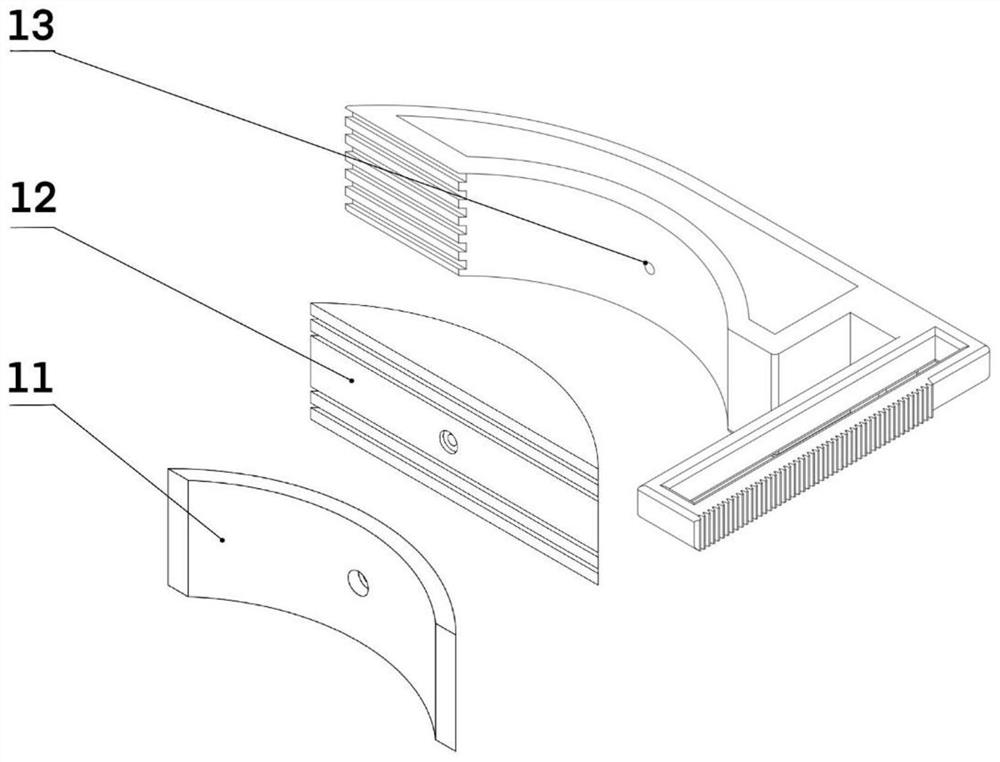

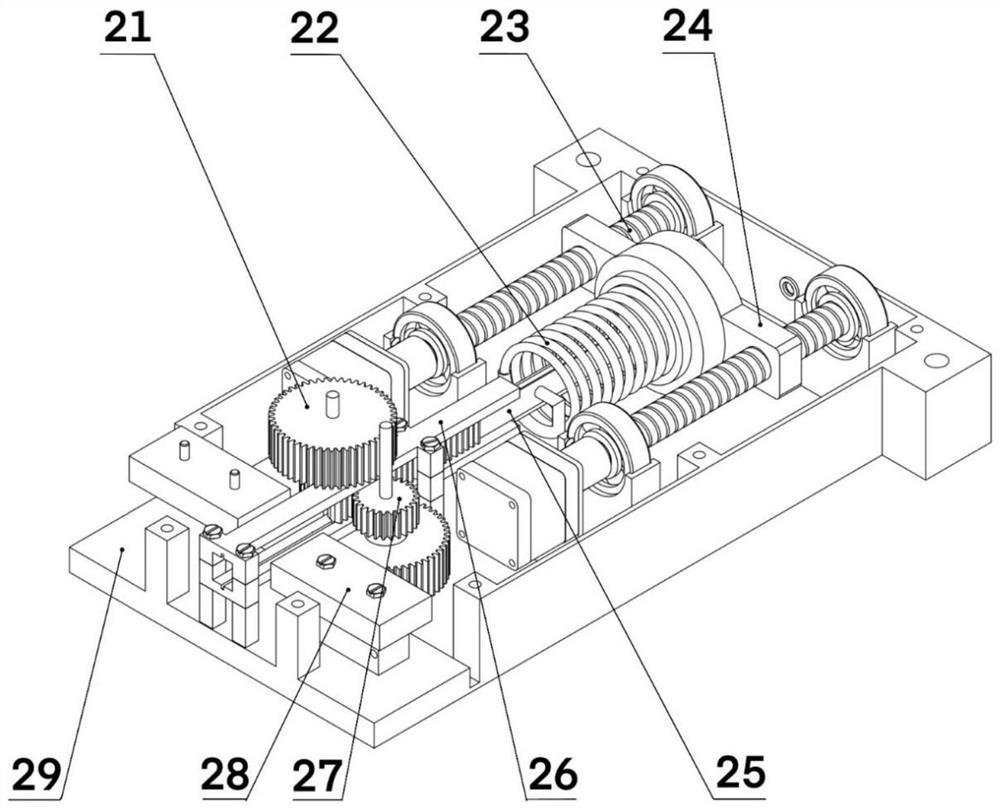

[0028] like figure 1 , figure 2 , image 3 , Figure 4 as well as Figure 5 As shown, the clamp-replaceable two-jaw manipulator includes a gripper (1), a gripper drive device (2), a support plate telescopic device (3), a support plate abutment adjustment device (4), a gripper (1) ) includes a flexible washer (11), a rigid spacer (12) and a clamp replacement hole (13), and the jaw drive (2) includes a large gear (21), a spring (22), a lead screw (23), a slider (24), rack (25), rack rail (26), pinion (27), clamping claw fixing block (28) and drive device housing (29), the support plate telescopic device (3) includes a support The backing plate (31), the supporting backing board driven rod (32), the backing backing board active rod (33), the backing backing board sticking adjustment device (4) comprising the backing pad platform shell (41), the backing pad platform active rod (42), a supporting pad platform driven rod (43), and a supporting pad platform guide column (44). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com