Fuel cell membrane electrode coating and feeding device and method

A fuel cell membrane and coating technology, used in fuel cells, battery electrodes, devices for coating liquids on surfaces, etc. Weight and thermal inertia, large contact area, and the effect of avoiding heating up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, the present invention will be further described as follows:

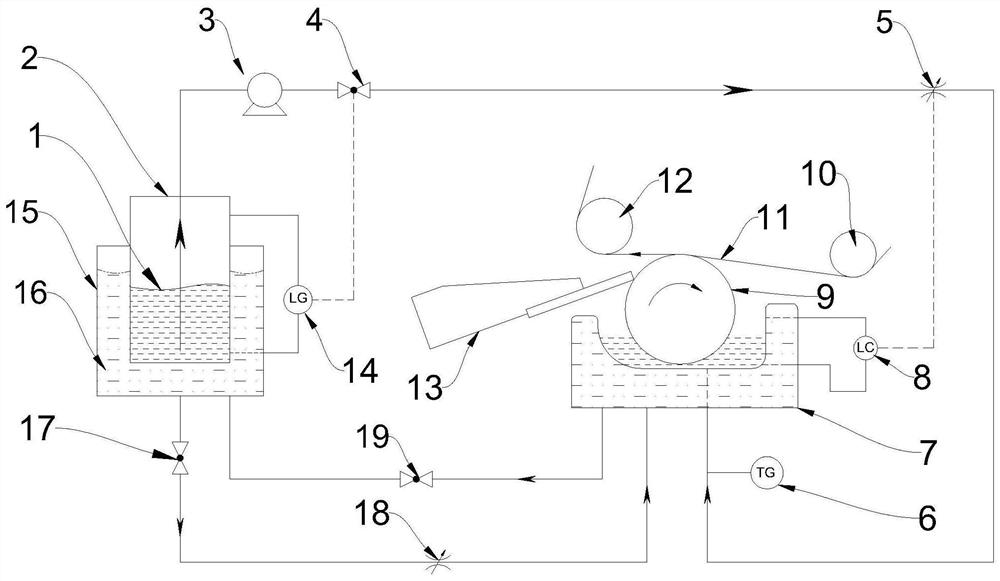

[0029] as attached figure 1As shown, the present invention provides a fuel cell membrane electrode coating and feeding device, including a slurry tank 2, a slurry tank 7, a low-temperature constant temperature tank 15, and a refrigerant 16 is injected into the low-temperature constant temperature tank 15, and the slurry tank 2 Placed in the low-temperature constant temperature tank 15, the slurry tank 2 is injected with the slurry 1, the bottom of the slurry 1 in the slurry tank 2 is inserted with a slurry extraction pipe, and the other end of the slurry extraction tube is connected to the slurry pump 3, and the slurry pump 3 is used to extract the slurry 1 in the slurry tank 2 and pressurize it to discharge. The output end of the slurry pump 3 is connected to the slurry tank 7 through a pipeline, and the pipeline between the slurry pump 3 and the slurry tank 7 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com