Ceramic composite nanofiltration membrane for dye removal and preparation method thereof

A ceramic composite and nanofiltration membrane technology, applied in the field of membrane separation, can solve the problem that composite nanofiltration membrane cannot achieve efficient separation of dyes and inorganic salts, and achieves good retention effect, good solvent resistance, and improved stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

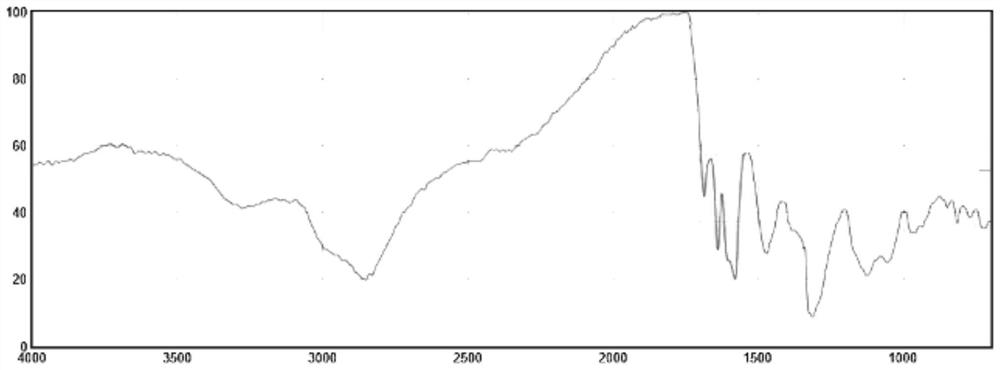

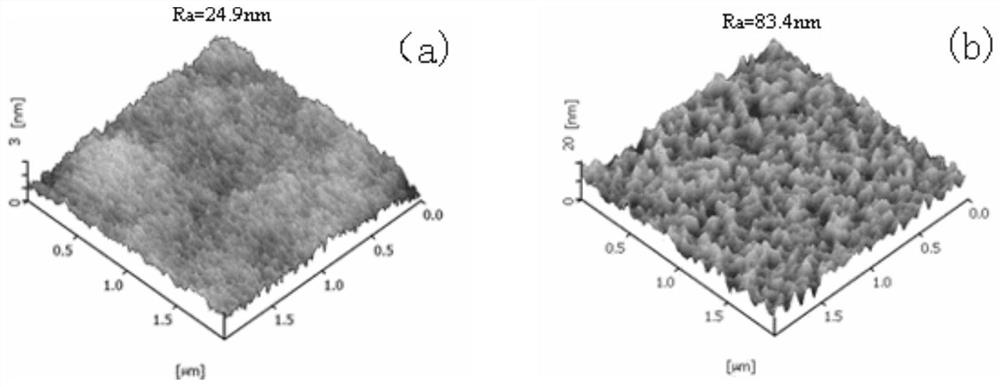

Image

Examples

Embodiment 1

[0050] First, ZrO with an average pore size of 3 nm 2 The membrane was soaked in deionized water and pre-wetted for 3 h, then removed and wiped dry. Next, prepare a 50 mM trihydroxymethane solution with a pH of 8.5 at room temperature, add 2 mg / mL dopamine (DA) and 2 mg / mL polyethyleneimine with a molecular weight of 600 Da to the trihydroxymethane solution, well mixed. Soak the pre-wetted ceramic membrane in the mixed solution, shake it for 6 hours, take it out, wash and dry it; then soak it in a 0.01 M titanium tetrafluoride solution with a pH of 3 at 50 °C for 0.5 hours, take it out, wash it and dry it; then soak it In a trihydroxymethane solution (50 mM, pH 8.5) containing 2 mg / mL gallic acid for 20 min, the resulting membrane was taken out and dried to obtain a ceramic composite nanofiltration membrane.

Embodiment 2

[0052] First, SiO with an average pore size of 20 nm 2 The membrane was soaked in deionized water and pre-wetted for 3 h, then removed and wiped dry. Then configure a 50 mM trimethylol solution with a pH of 8.5 at room temperature, add 2 mg / mL of tannic acid and 2 mg / mL of polyethyleneimine with a molecular weight of 600 Da to the trimethylol solution, and mix uniform. Soak the pre-wetted ceramic membrane in the mixed solution, shake it for 6 h, take it out, wash and dry it; then soak it in 0.07 M titanium tetrafluoride solution with pH 4 at 20 °C for 1 h, take it out, wash it and dry it; then After immersing in a trihydroxymethane solution (50 mM, pH 8.5) containing 2 mg / mL gallic acid for 120 min, the obtained membrane was taken out and dried. The above is a preparation process, and the process is cyclically operated 10 times to obtain a ceramic composite nanofiltration membrane.

Embodiment 3

[0054] First, SiO with an average pore size of 5 nm 2 The membrane was soaked in deionized water and pre-wetted for 3 h, then removed and wiped dry. Next, a 50 mM trimethylol methane solution with a pH of 8.5 was prepared at room temperature, and 2 mg / mL of catechol and 2 mg / mL of polyethyleneimine with a molecular weight of 600 Da were added to the trimethylol methane solution, well mixed. Soak the pre-wetted ceramic membrane in the mixed solution, shake it for 6 h, take it out, wash and dry; then soak it in 0.04 M titanium tetrafluoride solution with pH 5 at 70 ℃ for 3 h, take it out, wash and dry; then After immersing in a trihydroxymethane solution (50 mM, pH 8.5) containing 2 mg / mL gallic acid for 5 min, the obtained membrane was taken out and dried. The above is a preparation process, and the process is cyclically operated 4 times to obtain a ceramic composite nanofiltration membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com