Waste gas treatment device for environmental protection equipment

A waste gas treatment device and environmental protection equipment technology, applied in transportation and packaging, fixed filter element filter, dispersed particle filtration, etc., can solve problems such as endangering people's health, poor waste gas treatment effect, and polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

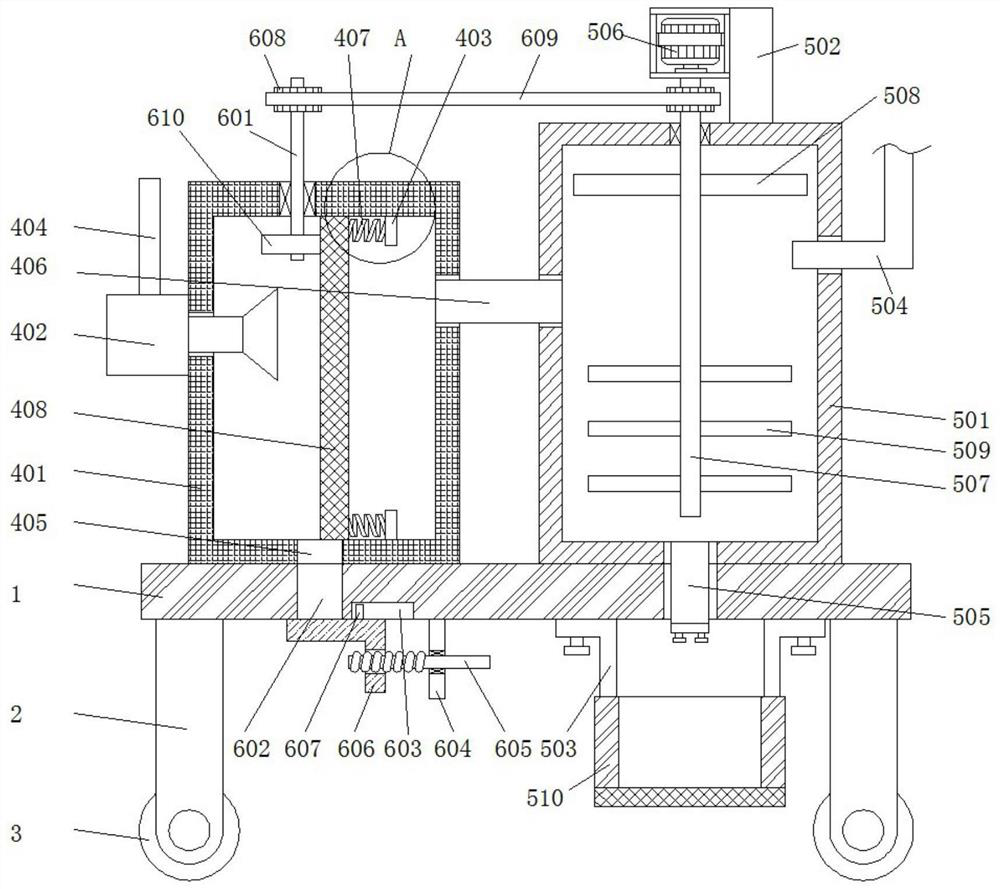

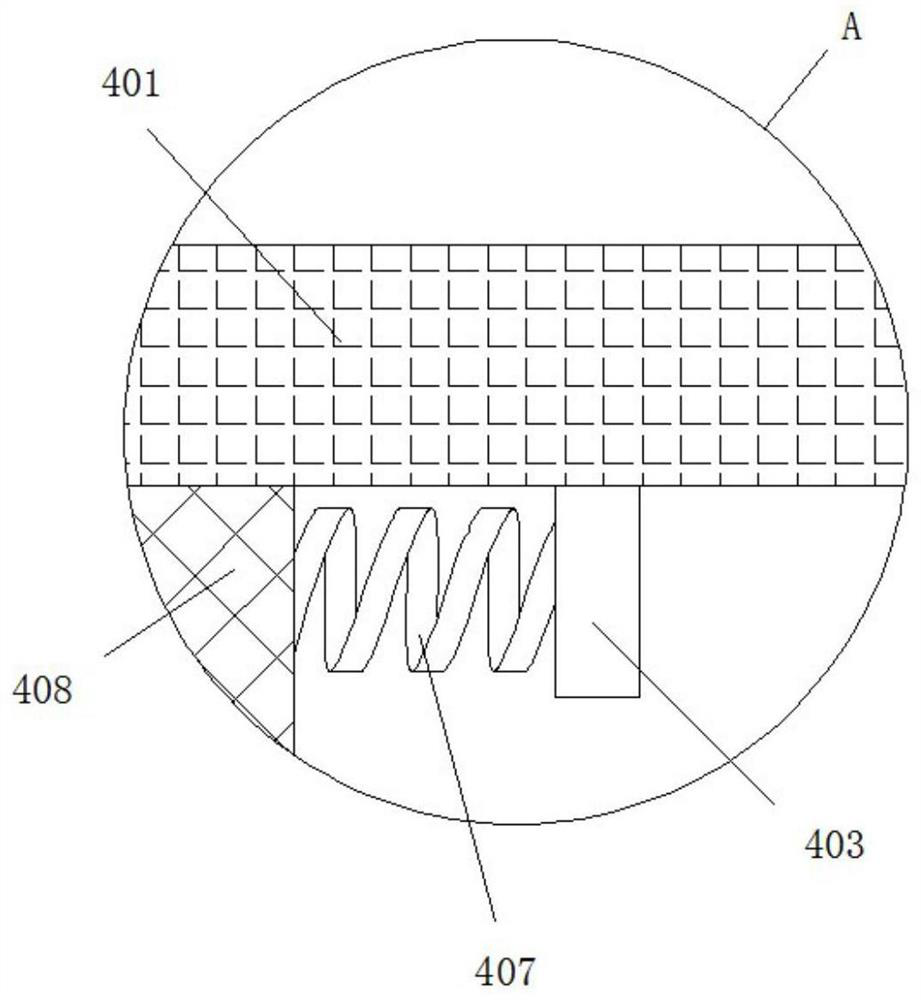

[0028] An exhaust gas treatment device for environmental protection equipment, including a base 1, and a floating object filtering mechanism. Both sides of the bottom of the base 1 are symmetrically fixed with a support plate 2, and the bottom of the support plate 2 is provided with a roller 3; the floating object filter The mechanism is located on the left side of the top of the base 1. The floating substance filtering mechanism includes a filter box 401, an aspirator 402 and a fixed block 403. The filter box 401 is fixed on the top of the base 1, and the aspirator 402 is fixed on the filter box. On the left side of 401 , the aspirator 402 is provided with a suction pipe 404 , and the suction pipe 404 extends to the inside of the filter box 401 .

[0029] Wherein, the bottom of the filter box 401 is provided with a long groove 405 , and the right side of the filter box 401 is fixedly connected with a connecting pipe 406 .

[0030] Wherein, the left sides of the two fixing blo...

Embodiment 2

[0032] The difference from Example 1 is that it also includes the following:

[0033] It also includes a hazardous substance processing mechanism, which includes a processing box 501, a fixing seat 502 and an L-shaped plate 503, the processing box 501 is fixed on the right side of the top of the base 1, and the fixing seat 502 is fixed on the top of the processing box 501 On the top, the L-shaped plate 503 is connected to the bottom of the base 1 by symmetrical bolts, the right end of the connecting pipe 406 is fixedly connected to the left side plate of the processing box 501, and the right side of the processing box 501 is fixedly connected to the liquid inlet. The pipe 504 is fixedly connected to the bottom of the processing box 501 with a discharge pipe 505 .

[0034] Wherein, a motor 506 is fixedly connected to the left side of the fixing base 502, and a long axis 507 is fixedly connected to the output shaft of the motor 506. And mixing rod 509, fan blade 508 is position...

Embodiment 3

[0037] The difference from Example 2 is that it also includes the following:

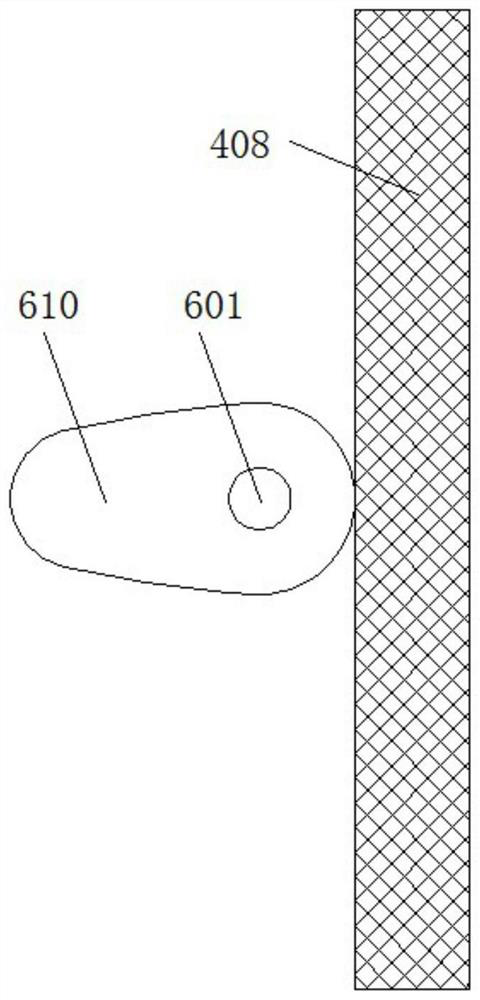

[0038] Also includes a cleaning mechanism, the cleaning mechanism includes a movable shaft 601, a through groove 602, a limit groove 603 and a square plate 604, the movable shaft 601 is rotatably connected to the top plate of the filter box 401, and the through groove 602 is located under the long groove 405, limiting The bit groove 603 is arranged on the bottom of the base 1, and the square plate 604 is fixedly connected to the bottom of the base 1. The square plate 604 is threaded with a threaded rod 605, and the left end of the threaded rod 605 is threaded with a clamping plate 606. The top of the clamping plate 606 It is slidably connected with the bottom of the base 1 , and the top of the clamping plate 606 is fixedly connected with a limiting block 607 , and the limiting block 607 is slidably connected inside the limiting groove 603 .

[0039] Wherein, the top of the movable shaft 601 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com