Combined slurry smashing and screening equipment based on composite smashing and rotation and straight pressure screening

A combined pulp screening technology, which is applied in textiles and papermaking, raw material separation, fiber raw material processing, etc., can solve the problems of single pulp screening method, low pulp quality, and low pulping efficiency, so as to increase crushing efficiency and improve Slurry quality, effect of preventing accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

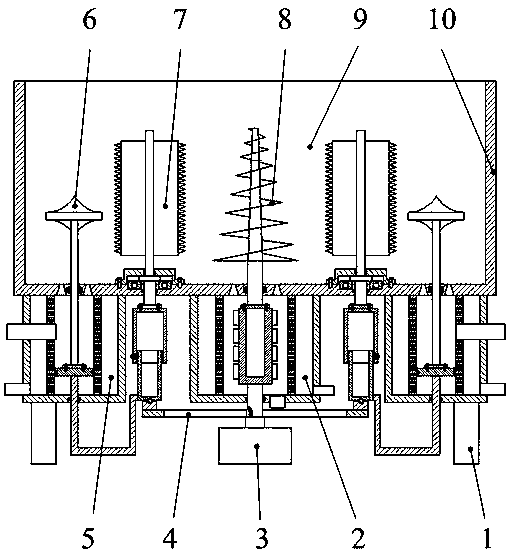

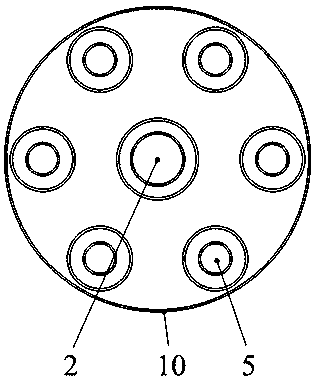

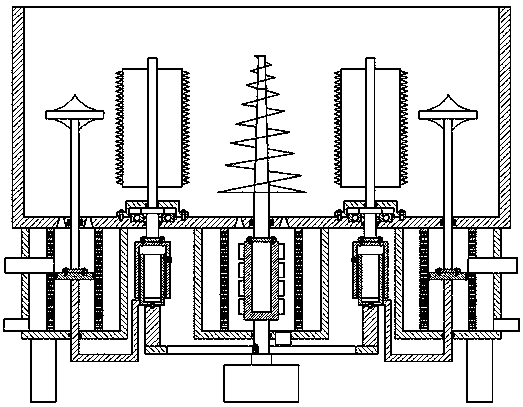

[0043] like figure 1 , figure 2 and image 3 As shown, a combined crushing and screening equipment based on compound crushing and rotary and direct pressure screen of the present invention mainly includes a power drive device, a reciprocating drive device, a direct rotation device, a composite pulping device, and a spinning and screening device. and direct pressure sieving device, the reciprocating drive device is installed on the power drive device, the direct rotary device is installed on the reciprocating drive device, the compound pulping device is set above the power drive device, the spinning press sieve device and the direct pressure sieve device It is located below the compound pulping device, and the spinning press screening device is located inside the direct pressure screening device.

[0044] The present invention provides driving power for the equipment through the power drive device, that is, the power is transmitted to the reciprocating drive device, the dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com