A skin repair lotion and its application in skin repair and anti-wrinkle

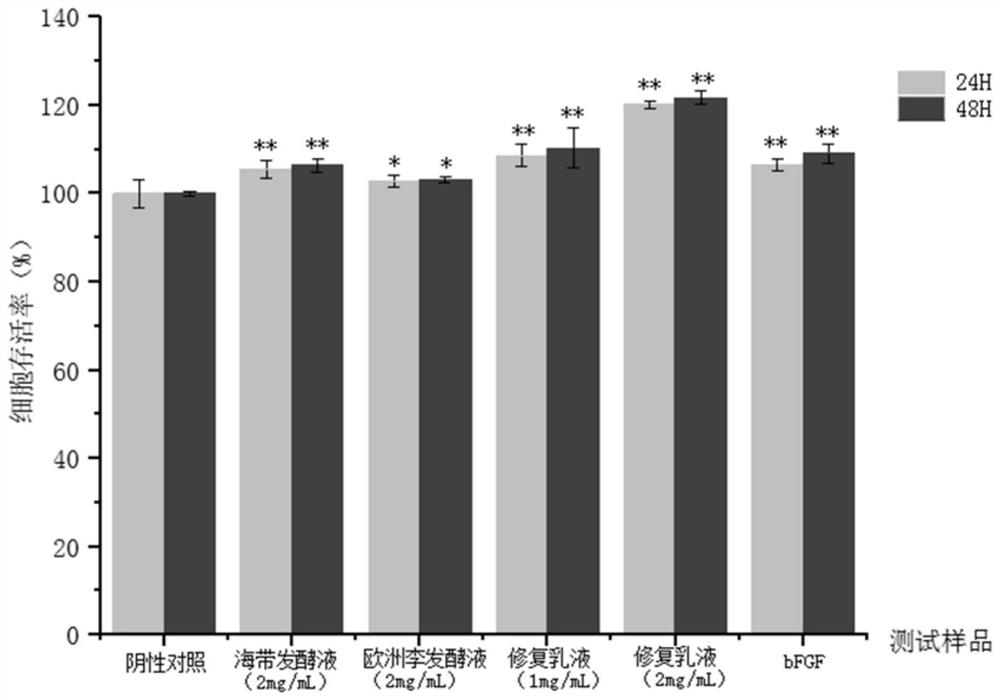

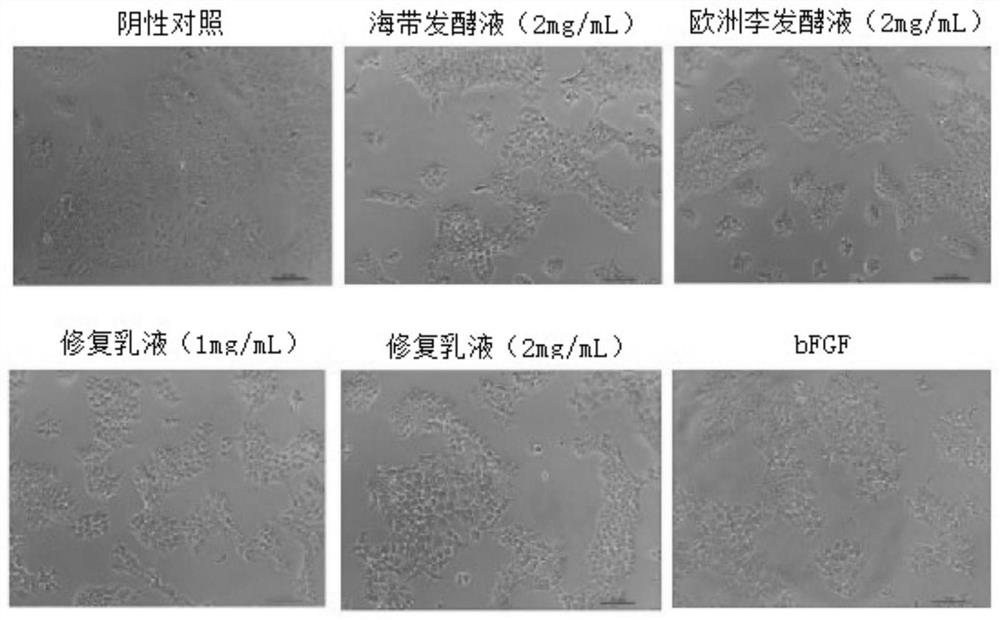

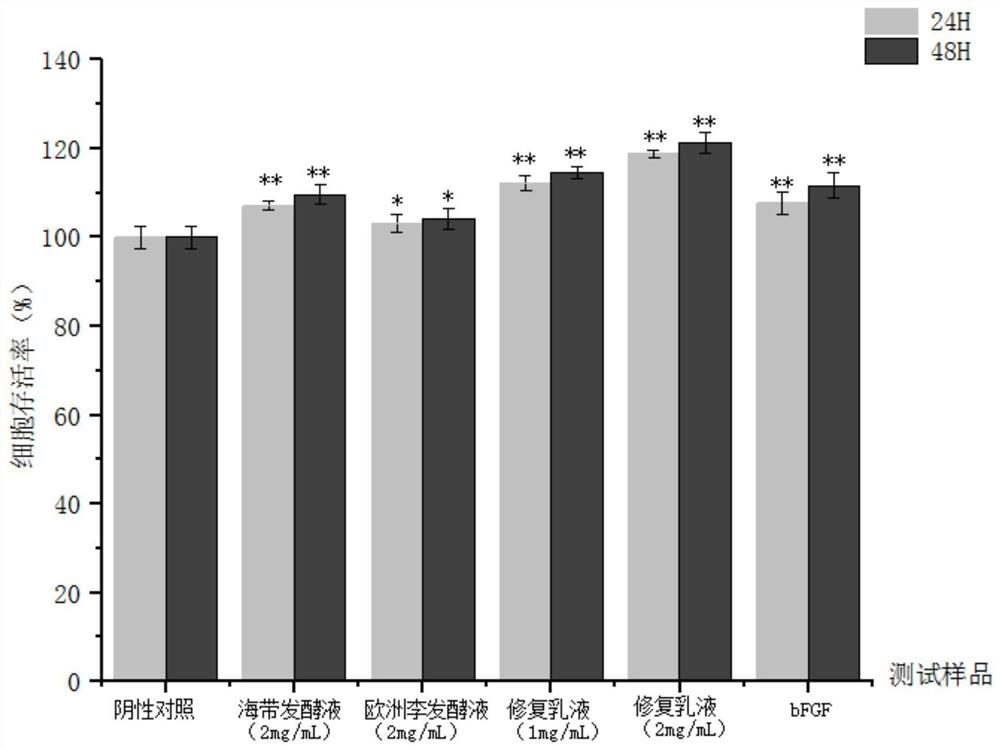

A skin repair and emulsion technology, applied in the field of skin care products, can solve the problems of few extraction and separation methods, and achieve the effect of good wrinkle removal effect, strong binding ability, and promotion of proliferation and migration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] Preparation of kelp fermentation liquid:

[0048] 1) Preprocessing of kelp:

[0049] Take a dried kernel, soak, clean the sediment and salt of the surface, ultra-fine pulverized to a particle size of about 10 μm, dry into powder, and use plasma beam irradiation to sterilize, and the irradiation intensity is 8000-9000 kGy;

[0050] 2) Bacillus subtilis culture

[0051] Bacillus subtilis (1L distilled water + 20 g of glucose + 15 g of protein + 5 g sodium chloride + 0.5 g beef paste + 20 g agar, pH = 7) were cultured, 35 ° C oscillated into 30-48 h, so that the culture solution Aggle content ≥10 9 CFU / ml.

[0052] 3) Fermented kelp powder

[0053] After the irradiation of kelp powder, the mixture was mixed in the microsporus culture solution of 10%, fermented 48 h; using the blend of Bacillus bacteria, the alpha-amylase, protease, lipase, cellulase, cellulase The enzyme-based decomposition kelp is obtained, and the fermentation broth is centrifuged for 30 min for 30 min, an...

Embodiment 1

[0062] Comparison: Toleral Fermentation Liquid 0.5g, European Li Faveriol 1g, serine 0.004 g, glycerified - October ketolaenate 1.5g, glycerol 5g, hexa glycol 0.6g, cameo seed oil 1.5g.

[0063] Preparation of emulsions: In a container, a kelp fermentation solution and European Lifa yeast are added, and the serine is added to dissolve, forming a liquid one; polyglycerol-Octa ketol, glycerol, hexanediol, and liquid, mix, form a liquid. Second; the stirring speed is turned on at 500r / min, and the catech oil is slowly added to the liquid 2. After mixing, 9000R / min is 6 min, it is repaired the emulsion.

Embodiment 2

[0065] Ratio: Toleral Fermentation Liquid 1g, European Li Favoride 0.5g, serine 0.001 g, alanine 0.002 g, PEG-60 hydrogenated castor oil 0.5g, bano-propanol 3g, pentanediol 2g, Hoghol oil 2.5g .

[0066] Preparation of emulsions: In a container, the kelp fermentation liquid and the European Li Dahyctirate are added, and serine and alanine are added to dissolve, form a liquid one; PEG-60 hydrogenated castor oil, domeliol, pentanediol, and liquid After mixing, the liquid is formed after mixing; the stirring speed is opened at 350 r / min, and the choleoba oil is slowly added to the liquid 2, and after mixing, the emulsion is repaired after 10000r / min is 5 min after mixing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com