Self-adaptive control system and self-adaptive control method for corn harvesting feeding amount

A self-adaptive control and feed rate technology, applied in applications, harvesters, cutters, etc., can solve the problem of not comprehensively considering the rate of grain breakage, the loss rate of ear picking, the entrainment loss rate, the maximum harvest efficiency and harvest quality, and the feed rate. It can solve problems such as quantitative subjectivity and uncertainty, and achieve the effect of ensuring reliability and scientificity, ensuring real-time performance and reliability, and reasonable and accurate vehicle speed control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

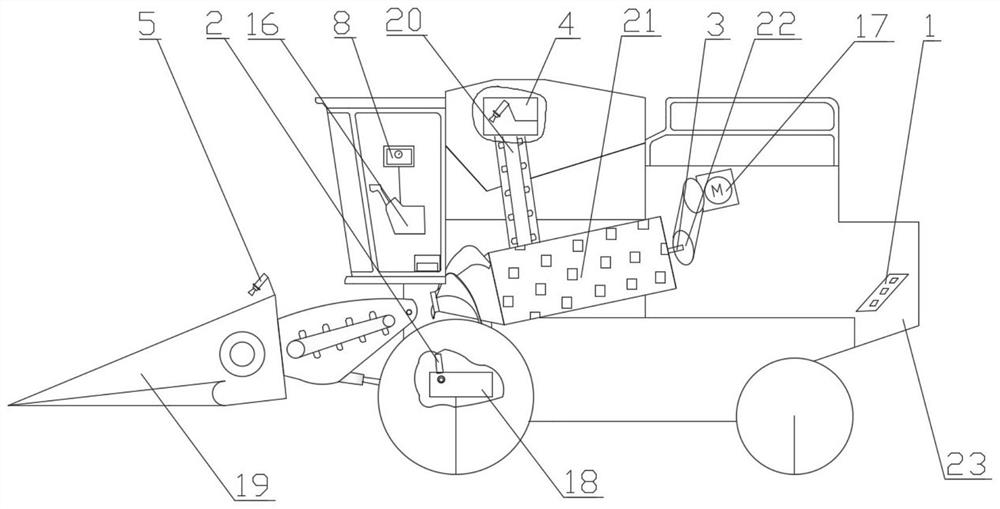

[0043] The corn harvester includes a cab, a granary, an engine 9, a gearbox 18, a header 19 and a drum 21.

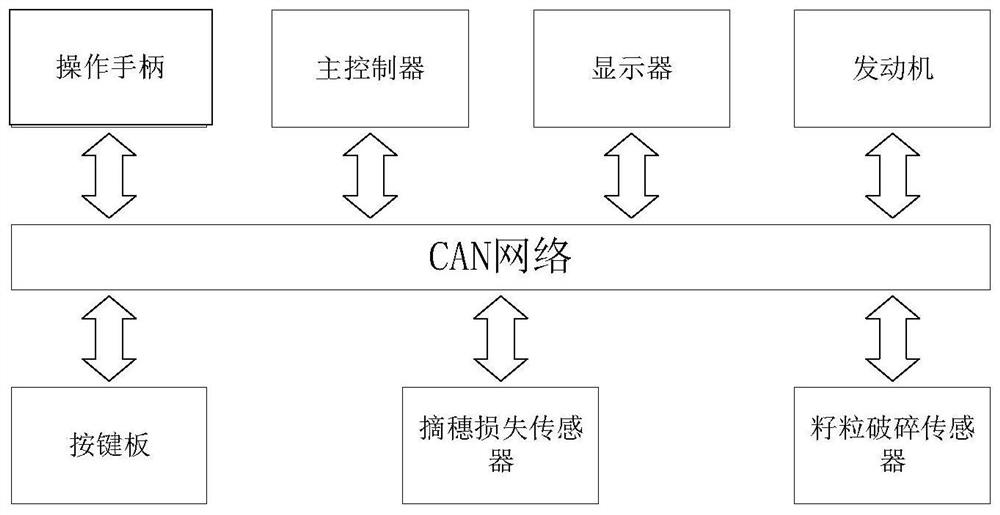

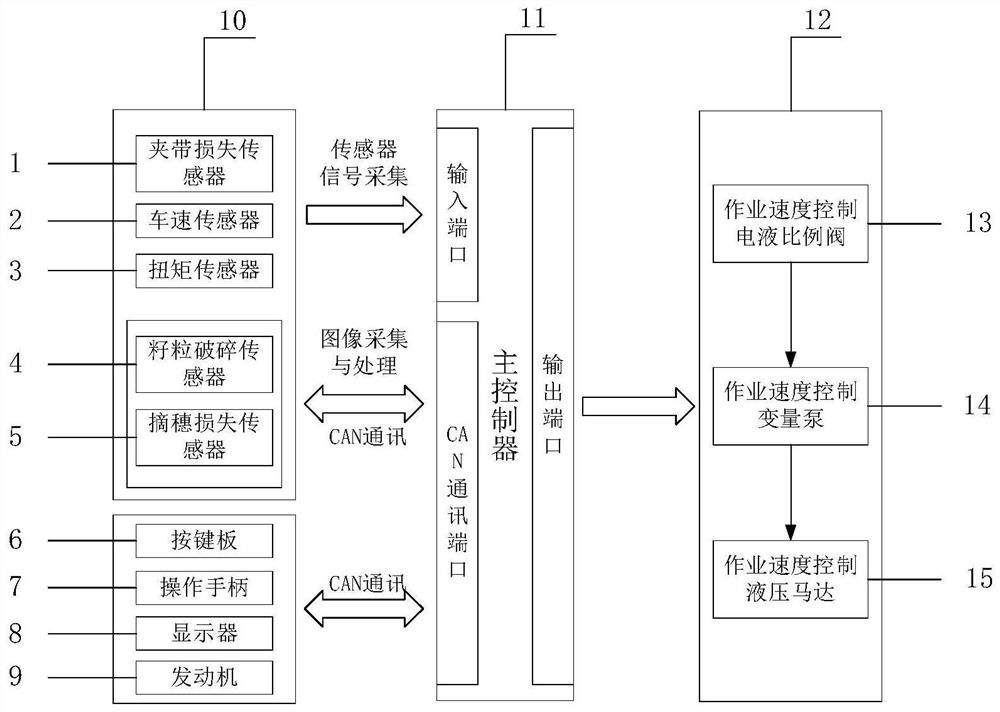

[0044] Such as figure 2 and image 3 As shown, an adaptive control system for feeding amount of corn harvesting includes a CAN bus, a measuring and transmitting device 10 , an armrest box assembly 16 , a display 8 , a main controller 11 and a hydraulic actuator 12 .

[0045] The hydraulic actuator 12 includes a working speed control electro-hydraulic proportional valve 13, a working speed control variable pump 14 and a working speed control hydraulic motor 15 connected in sequence; the working speed controlling hydraulic motor 15 is connected with the gearbox 18 of the corn harvester, Used to control the output speed of the gearbox 18. The operation speed control electro-hydraulic proportional valve 13 is connected with the pulse signal outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com