A high-strength moisture-proof and fire-proof power cable

A power cable, high-strength technology, applied in the field of high-strength moisture-proof and fire-proof power cables, can solve the problems that the automatic intelligent fire extinguishing ability cannot be realized, and there is no automatic wire feeding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

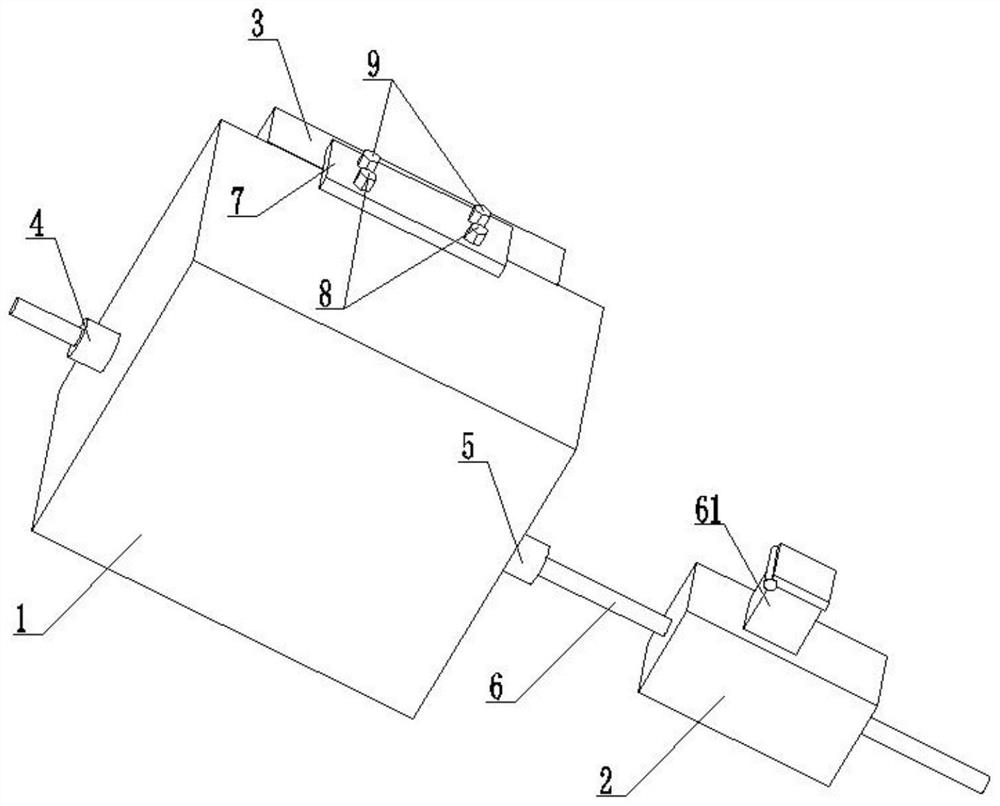

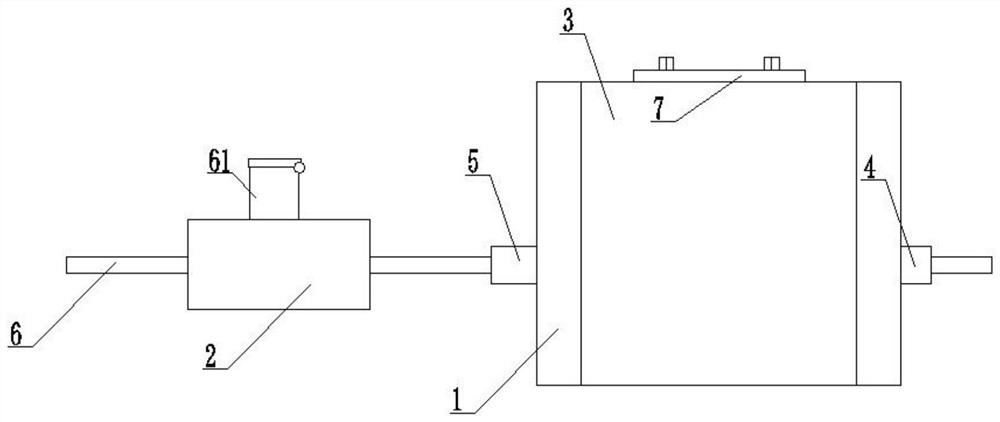

[0029] The present invention is described in detail below in conjunction with accompanying drawing:

[0030] refer to Figure 1 to Figure 10 A high-strength moisture-proof and fire-proof power cable provided by the present invention includes a wire feeding box 1, a moisture-proof and fire-proof box 2, and a cooling box 3. The left side of the wire feeding box 1 is provided with a left pipe socket 4, and the described The right side of the wire feeding box 1 is provided with a right pipe socket 5, the top surface of the wire feeding box 1 is fixedly connected to the rear end of the top plate 7 through the first series of bolt groups 8, and the cooling box 3 The top surface is fixedly connected to the front end of the top plate 7 through the second series of bolt groups 9, the inside of the wire feeding box 1 is provided with a wire storage box 10, and the left side of the wire storage box 10 is provided with a left outlet port 11. The right side of the wire storage box 10 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com