A production process of liquid helium-free skeleton superconducting magnet

A technology for superconducting magnets and production processes, which is applied in the manufacture of inductors/transformers/magnets, coils, and electrical components. It can solve problems such as superconducting wire insulation rupture, superconducting coil scrapping, and superconducting wire breakage, so as to reduce damage, The effect of reducing loss and reducing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0052] The invention discloses a production process of a liquid-helium-free skeleton-free superconducting magnet, which is used for forming a liquid-helium-free skeleton-free superconducting magnet.

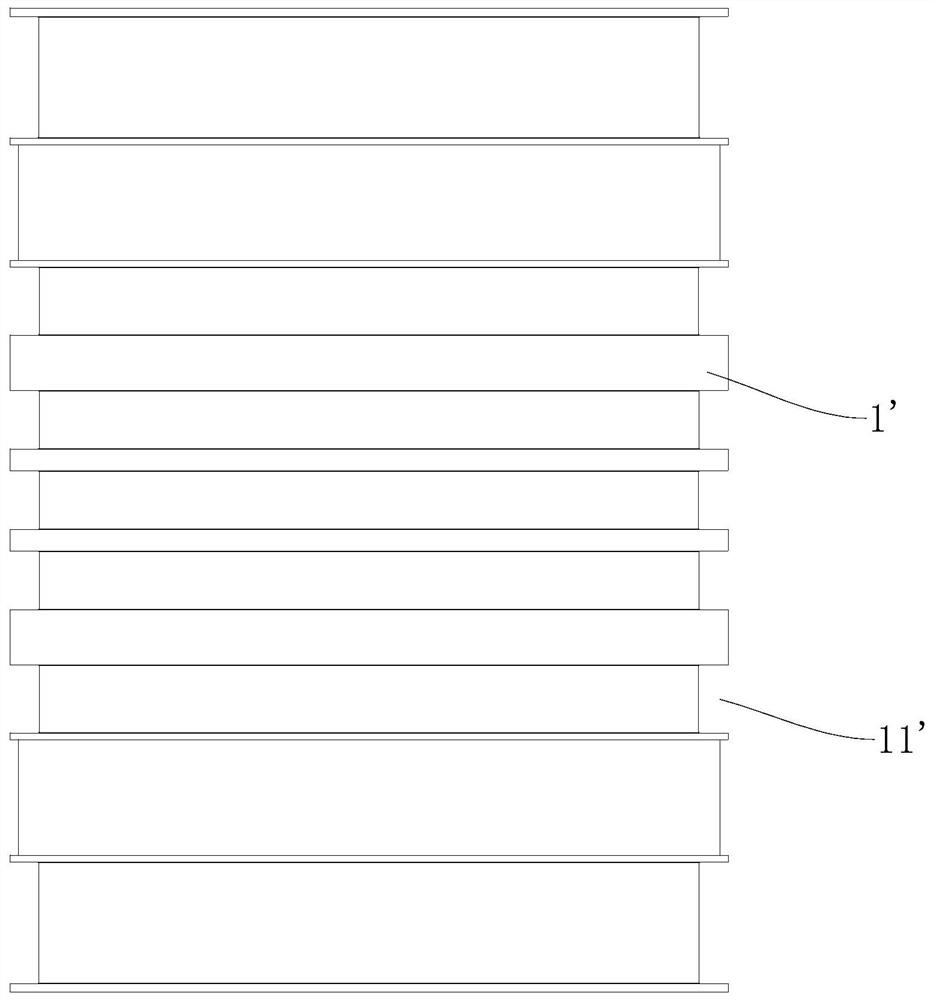

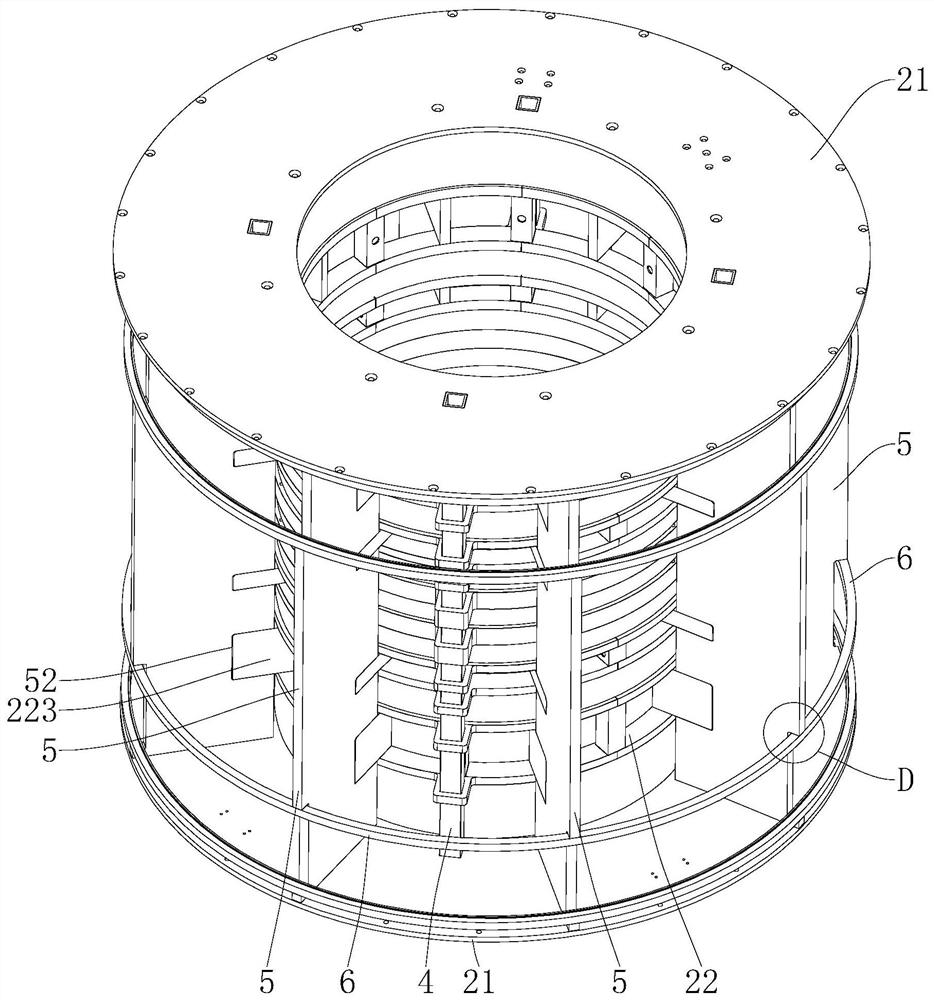

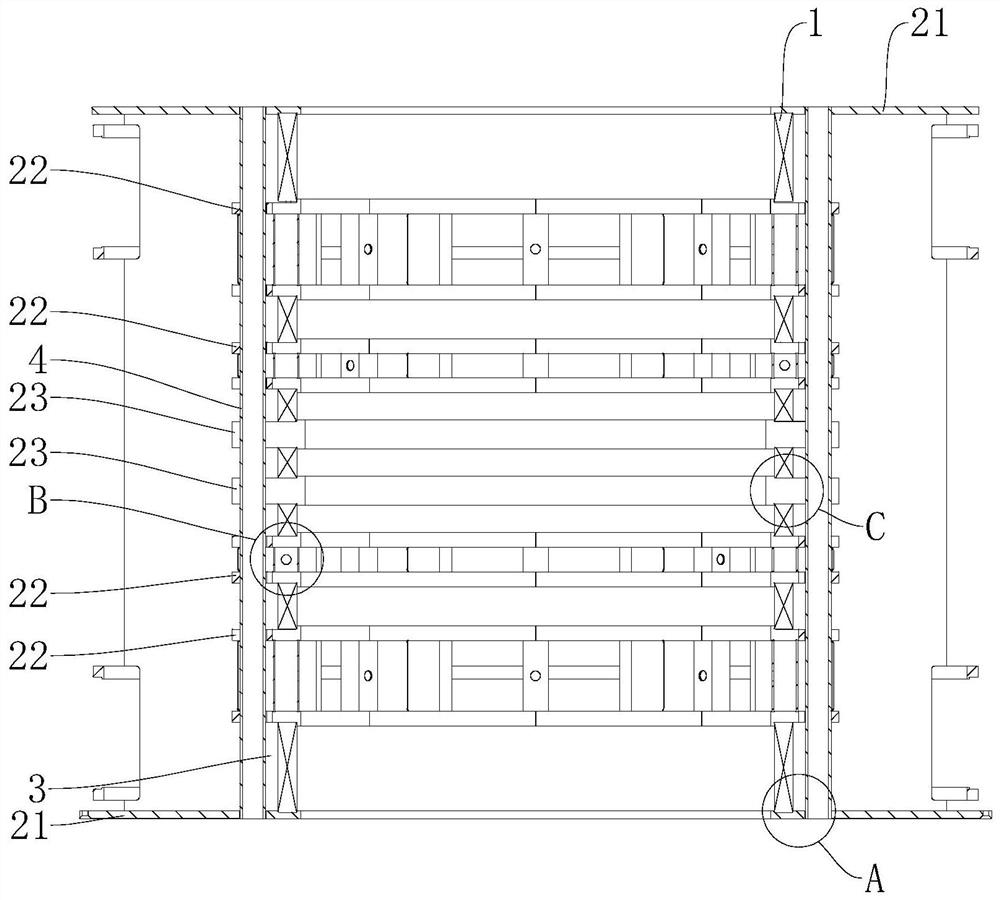

[0053] refer to figure 2 and image 3 , a liquid helium-free frameless superconducting magnet, comprising a mounting frame and seven superconducting coils 1 mounted on the mounting frame. In this embodiment, the superconducting coil 1 is wound by a winding machine, and each layer of superconducting wire is brushed with a layer of resin to shape the superconducting wire, so the superconducting coil 1 is cylindrical and not easy to disperse. .

[0054] The mount includes eight spaced apart supports. An installation gap 3 for installation of the superconducting coil 1 is formed between adjacent supports. Wherein, the supporting parts include end supporting pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com