A Wire Burst Enhanced Microcapillary Pulsed Plasma Thruster

A technology of pulsed plasma and microcapillary, which is applied in the direction of using plasma, thrust reverser, machine/engine, etc., can solve the problems of complicated external trigger system, limit the life of spark plug, and small output element impulse, so as to expand the output range , Reduce the volume of the device and enhance the effect of the output element impulse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

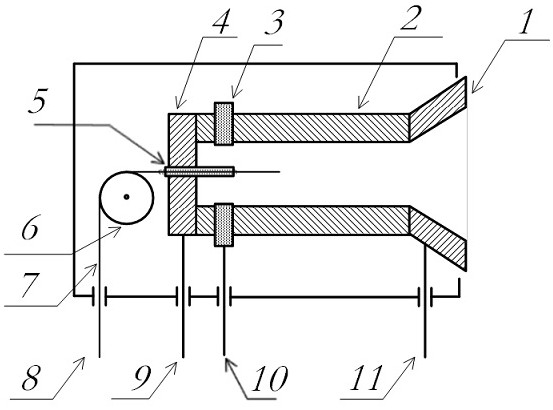

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0025] Please refer to figure 1 , the wire burst enhanced microcapillary pulsed plasma thruster includes:

[0026] anode nozzle 1;

[0027] A capillary cavity 2, the capillary cavity 2 is installed on one side of the anode nozzle 1;

[0028] a trigger electrode 3, the trigger electrode 3 is arranged on the capillary cavity 2;

[0029] A cathode base 4, the cathode base 4 is installed on the side of the capillary cavity 2 away from the anode nozzle 1, and a central hole is opened in the center of the cathode base 4;

[0030] A metal wire 7 , one end of the metal wire 7 passes through the middle hole and extends into the capillary cavity 2 .

[0031] Both ends of the capillary cavity 2 are provided with internal threads, and the anode nozzle 1 and the cathode base 4 are provided with external threads. The anode nozzle 1, the capillary cavity 2 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com