An ultra-thin composite optical film based on pmma/pc and its preparation method and application

An optical film, ultra-thin technology, used in optics, optical components, instruments, etc., can solve the problems of cumbersome stretching method, can not meet the requirements of optical film, different thickness, etc., to overcome difficult processing characteristics, Improved film strength, flexibility, and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

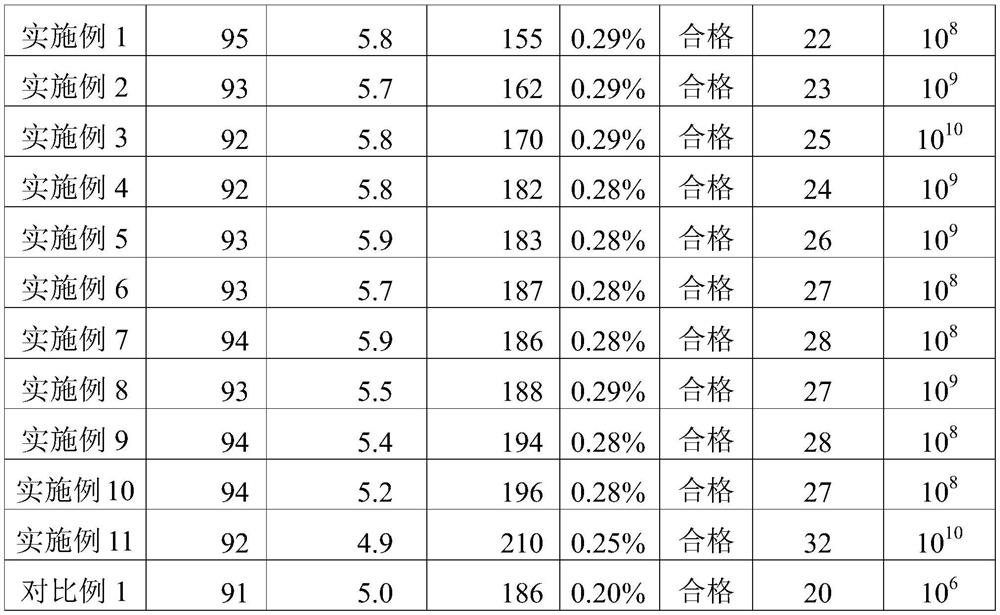

Examples

Embodiment 1

[0034] An ultra-thin composite optical film based on PMMA / PC, comprising raw materials in the following weights:

[0035] Optical grade PMMA 5Kg, optical grade PC 5Kg, sodium dodecylbenzene sulfonate 0.05Kg, polybutadiene rubber 0.05Kg, polysiloxane 0.02Kg, modified antistatic agent 0.02Kg, tetraethylene glycol monohard Fatty acid ester 0.01Kg, fluorinated polyethylene 0.01Kg; the modified antistatic agent is composed of 0.002Kg lithium trifluoromethanesulfonimide and 0.018ASA by weight, specifically: heating ASA to 350°C by microwave, Take it out, continue to add lithium trifluoromethanesulfonimide at 350° C., stir at 1000 rpm for 30 minutes, cool naturally, pulverize, and pass through a 500-mesh sieve to obtain a modified antistatic agent.

[0036] A preparation method of an ultra-thin composite optical film based on PMMA / PC, comprising the following steps:

[0037] S1. mix the optical grade PMMA, optical grade PC, sodium dodecyl benzene sulfonate, polybutadiene rubber, pol...

Embodiment 2

[0042] An ultra-thin composite optical film based on PMMA / PC, comprising raw materials in the following weights:

[0043] Optical grade PMMA 8Kg, optical grade PC 8Kg, sodium dodecylbenzene sulfonate 0.08Kg, polybutadiene rubber 0.08Kg, polysiloxane 0.025Kg, modified antistatic agent 0.025Kg, tetraethylene glycol monohard Fatty acid ester 0.02Kg, fluorinated polyethylene 0.02Kg; the modified antistatic agent is composed of 0.0025Kg lithium trifluoromethanesulfonimide and 0.0225Kg ASA by weight, specifically: heating ASA to 350°C by microwave, Take it out, continue to add lithium trifluoromethanesulfonimide at 350° C., stir at 1000 rpm for 30 minutes, cool naturally, pulverize, and pass through a 500-mesh sieve to obtain a modified antistatic agent.

[0044] A preparation method of an ultra-thin composite optical film based on PMMA / PC, comprising the following steps:

[0045] S1. mix the optical grade PMMA, optical grade PC, sodium dodecyl benzene sulfonate, polybutadiene rubber...

Embodiment 3

[0050] An ultra-thin composite optical film based on PMMA / PC, comprising raw materials in the following weights:

[0051] Optical grade PMMA 10Kg, optical grade PC 10Kg, sodium dodecylbenzene sulfonate 0.1Kg, polybutadiene rubber 0.1Kg, polysiloxane 0.03Kg, modified antistatic agent 0.03Kg, tetraethylene glycol monohard Fatty acid ester 0.03Kg, fluorinated polyethylene 0.03Kg; the modified antistatic agent is composed of 0.003Kg lithium trifluoromethanesulfonimide and 0.027Kg ASA by weight, specifically: heating ASA to 350°C by microwave, Take it out, continue to add lithium trifluoromethanesulfonimide at 350° C., stir at 1000 rpm for 30 minutes, cool naturally, pulverize, and pass through a 500-mesh sieve to obtain a modified antistatic agent.

[0052] A preparation method of an ultra-thin composite optical film based on PMMA / PC, comprising the following steps:

[0053] S1. mix the optical grade PMMA, optical grade PC, sodium dodecyl benzene sulfonate, polybutadiene rubber, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com