Automatic passing-through type grinding machine

A grinding machine, automatic technology, applied in the direction of grinding machine, grinding machine parts, grinding feed movement, etc., can solve the problem of low processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

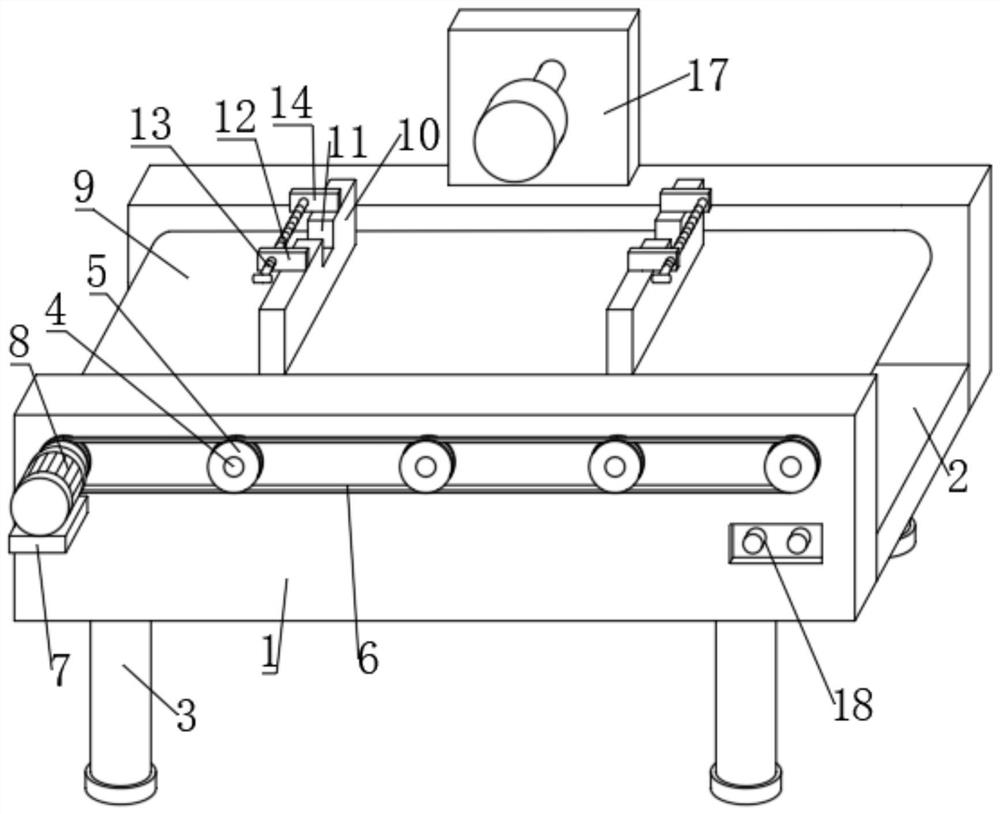

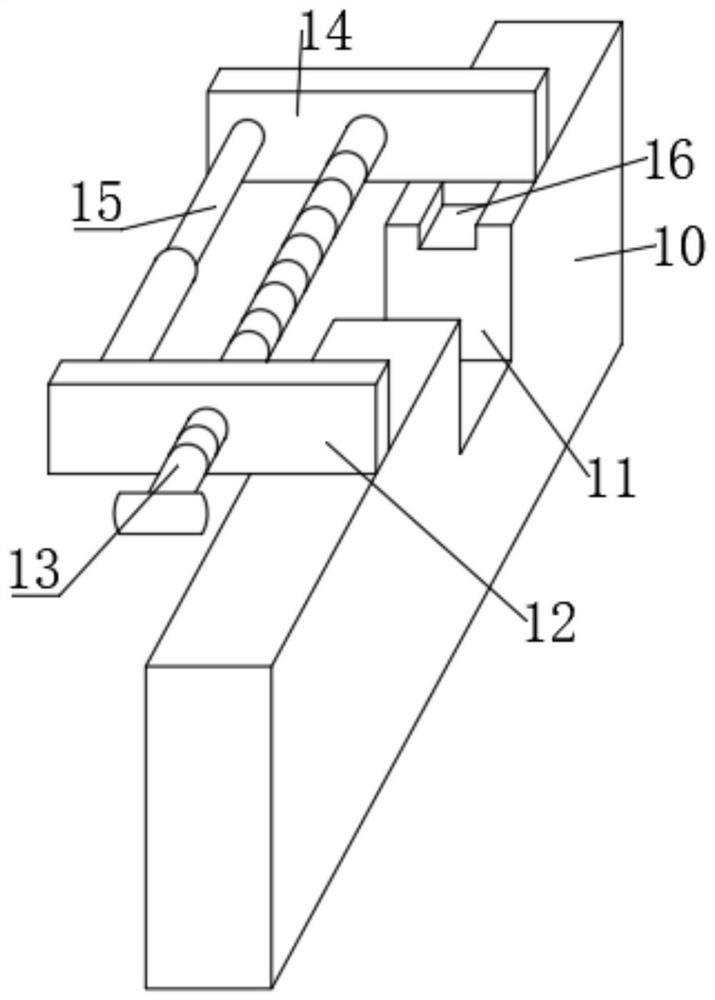

[0021] refer to Figure 1-3 , an automatic through-type grinding machine, including a bottom plate 2, two side plates 1 are fixed symmetrically by bolts at both ends of the bottom plate 2, and the front end of one side plate 1 is connected with a plurality of straight shafts 4 through hinge rotation, and the front ends of the straight shafts 4 are connected by bolts The pulley 5 is fixed, and the same belt 6 is sleeved on multiple pulleys 5. The rear end of the straight shaft 4 is welded with a transmission roller, and the transmission roller is arranged between two side plates 1. The transmission rollers are sleeved with For the same conveyor belt 9, the top of the conveyor belt 9 is provided with a fixing mechanism, the front end of the side plate 1 is fixed with a support plate 7 by bolts, the top of the support plate 7 is fixed with a motor 8, the output shaft of the motor 8 is connected with a reducer, and the output shaft of the reducer and One of the pulleys 5 is connec...

Embodiment 2

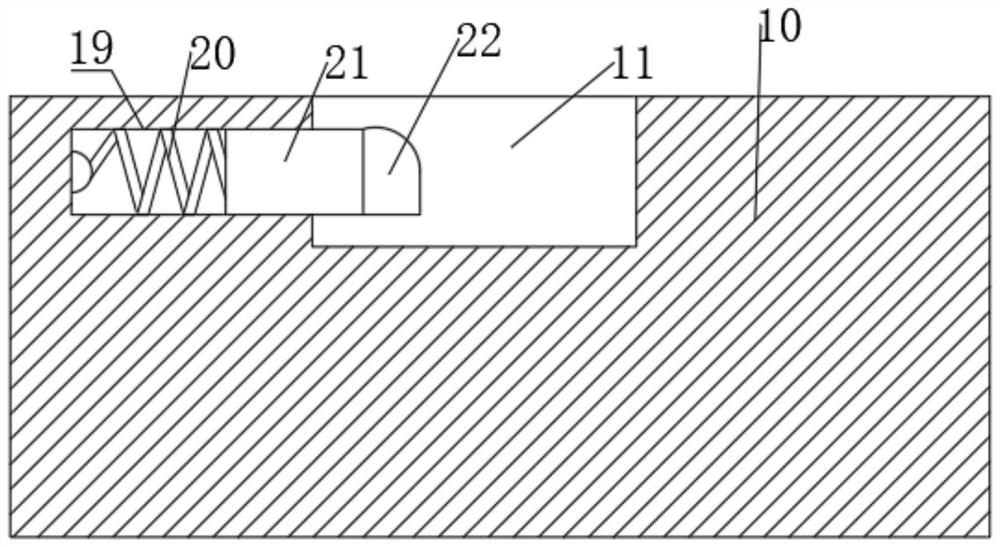

[0025] refer to Figure 1-3 , an automatic pass-through grinding machine, the fixed plate 10 is provided with a second chute 19, a spring 20 is welded in the second chute 19, a moving block 21 is welded at the rear end of the spring 20, and a limit block is welded at the rear end of the moving block 21 22. The top corner of the limit block 22 has rounded corners.

[0026] When in use, during the workpiece fixing process, the workpiece is first placed in the two slots 11, the spring 20 is compressed by force and exerts a reverse force on the moving block 21 due to its own elasticity, so that the limiting block 22 squeezes the workpiece, This facilitates subsequent operations of clamping and fixing the workpiece, and the top corners of the limiting block 22 are rounded, so that the workpiece can be placed in the slot 11 more conveniently.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com