DGT adsorption film, preparation method and method for monitoring perfluoro and polyfluoro compounds based on DGT technology

A technology of polyfluorinated compounds and adsorption membranes, applied in the direction of alkali metal compounds, separation methods, chemical instruments and methods, etc., can solve the problems of increased transportation costs and time costs, reduced monitoring accuracy, and cumbersome processing processes, etc., to achieve accurate The effect of monitoring, reducing monitoring costs, and simple operation of the method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

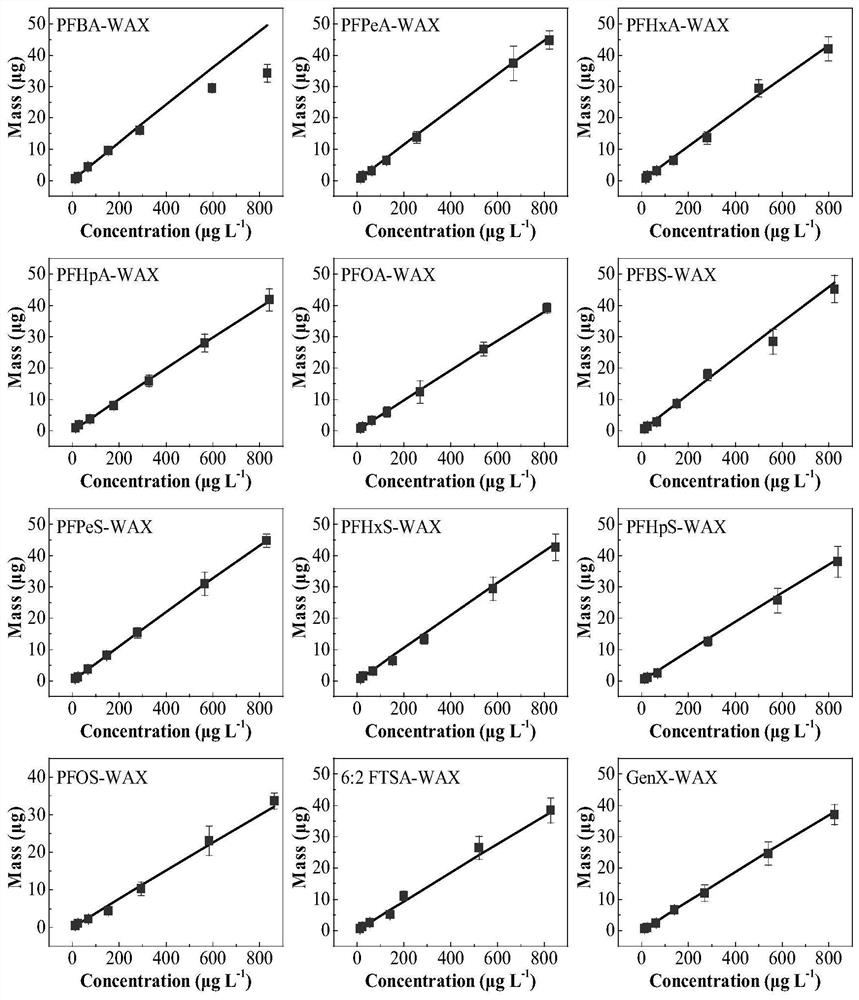

[0046] In this example, the WAX resin was used as the raw material to prepare the adsorption film, which was applied to the DGT technology, and the perfluorinated and polyfluorinated compounds existing in the water environment to be tested were determined by using the DGT technology. The specific detection steps are as follows:

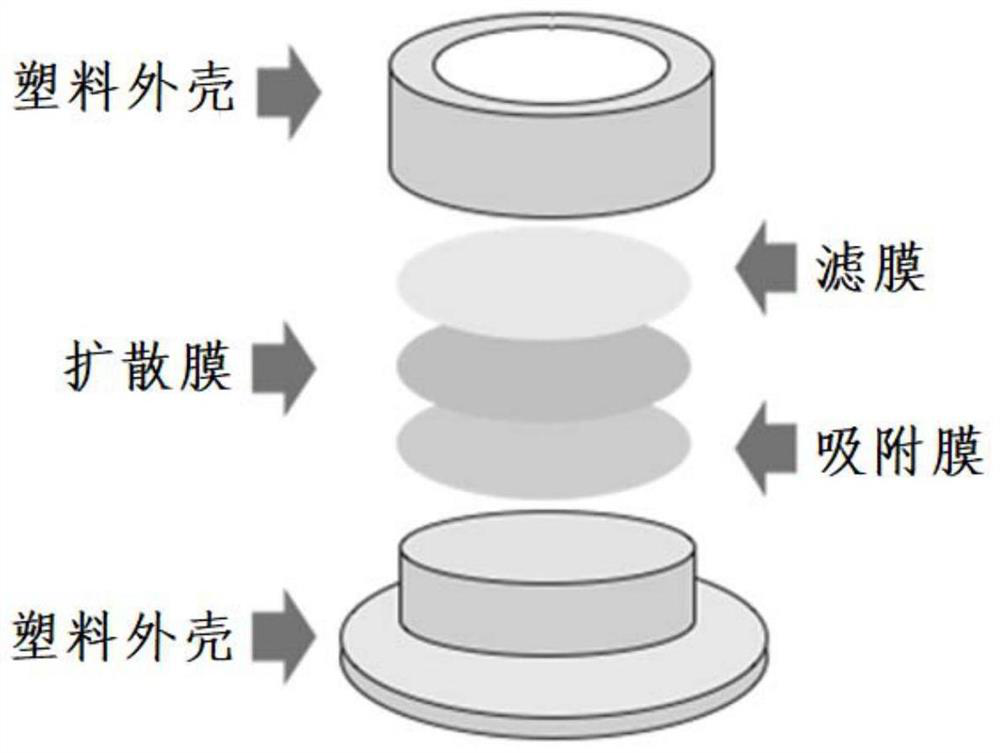

[0047] (1) Assembly of the DGT device: first place the DGT base on the clean bench, and spread the WAX resin adsorption film, diffusion film and filter film on the base with clean tweezers in turn, and then gently press the DGT cover on the base by hand , and finally press it tightly to assemble a DGT device (such as figure 1 shown), the base and cover of the DGT device are made of acrylonitrile-butadiene-styrene copolymer (Acrylonitrile butadiene styrene copolymer, ABS), and from top to bottom are filter membrane, diffusion membrane, adsorption membrane .

[0048] (2) Placement of the DGT device: put the DGT device in step (1) into well-stirred ...

Embodiment 2

[0067] In this example, the adsorption membrane distributed with WAX resin prepared in Example 1 was used as the binding membrane of the DGT device, the diffusion membrane was selected from agarose diffusion membrane, and the filter membrane was selected from PES polyethersulfone filter membrane.

[0068] The diffusion film was prepared as follows: before the preparation, the assembled and cleaned glass plates and spacers were placed in an oven at 70°C. Weigh 0.45g of agarose and 30mL of Milli-Q water into a conical flask, place the conical flask on an electric stove to heat, and when the aqueous solution becomes clear and about to boil, transfer the solution to the preheated In the glass plate, after standing at room temperature for 50 minutes, it can be cut into discs with a diameter of 2.51 cm with a mold.

[0069] Use DGT technology to determine the perfluorinated and polyfluorinated compounds in the water to be tested. The specific detection steps are as follows:

[0070...

Embodiment 3

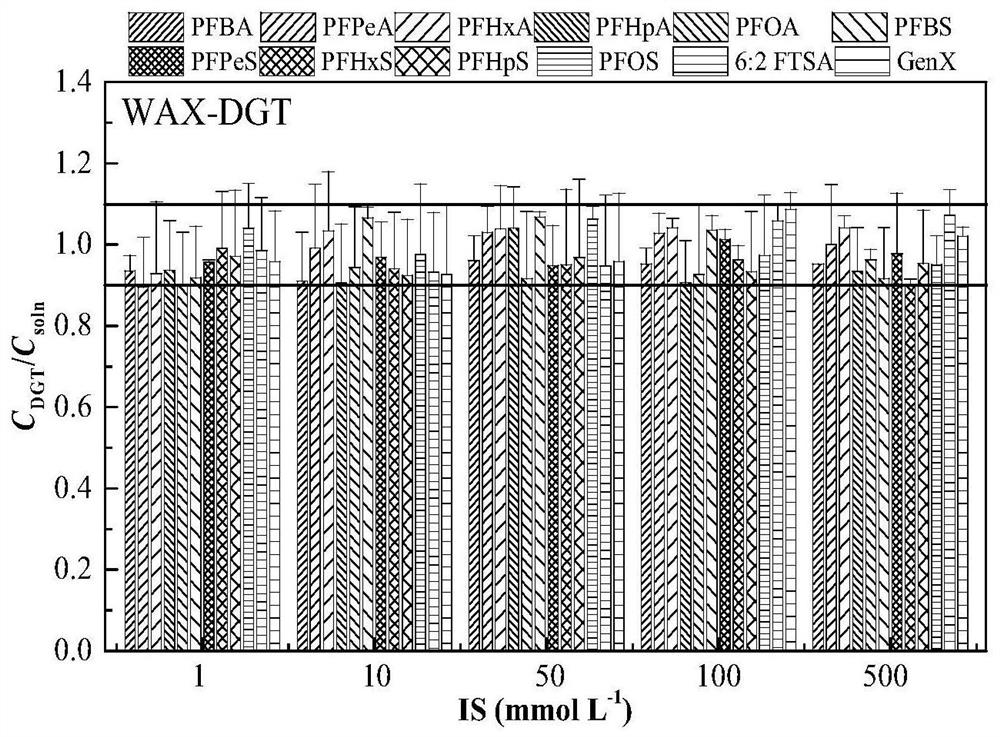

[0089] This example is basically the same as Example 2, except that the difference is that in this example, under different ionic strengths, the DGT technique is used to determine the influence of perfluorinated and polyfluorinated compounds in the water environment, wherein the perfluorinated and polyfluorinated compounds in the water to be tested are The concentration of the fluorine compound is 20 μg / L, and the ionic strength IS (calculated as NaCl) of the aqueous solution to be tested is respectively: 1, 10, 50, 100 and 500 mmol / L.

[0090] image 3 In order to use the DGT device in this embodiment to adsorb various perfluorinated and polyfluorinated compounds under different ionic strengths, the concentration measured by WAX-DGT is basically the same as the solution concentration;

[0091] Such as image 3 As shown, the concentration of perfluorinated and polyfluorinated compounds calculated according to the formula C DGT Compared with the actual measurement of the conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com