Liquid-deficient monitor for transparent pipeline

A monitor and transparent tube technology, which is applied in the field of liquid shortage monitors in transparent pipelines, can solve the problems of leakage observation, slow response speed, labor-intensive and other problems, and achieve the effect of automatic detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

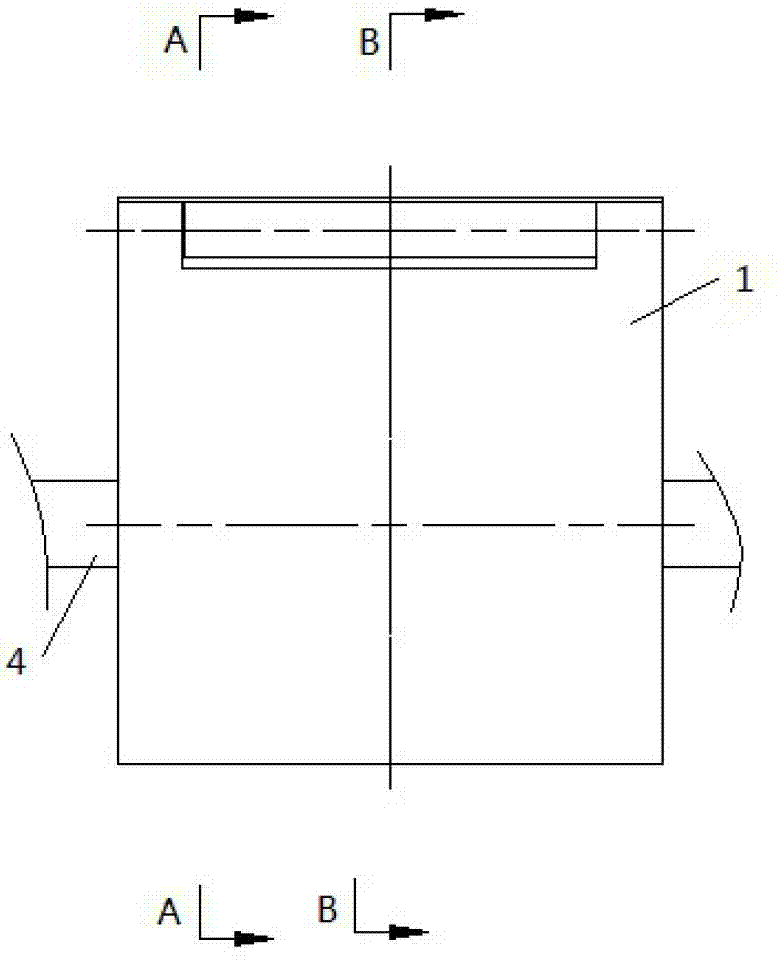

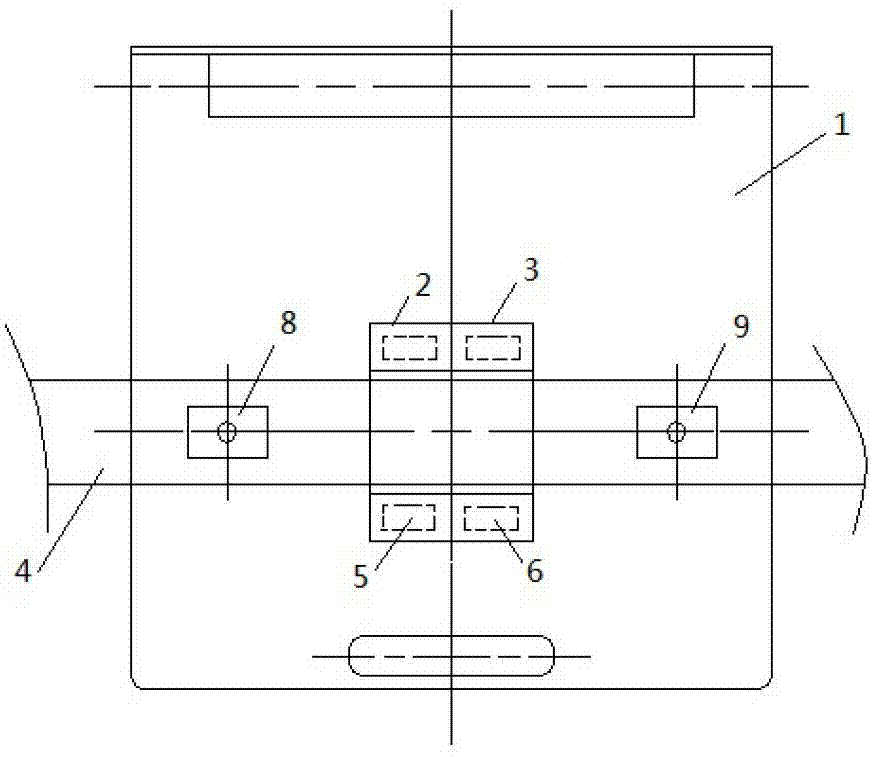

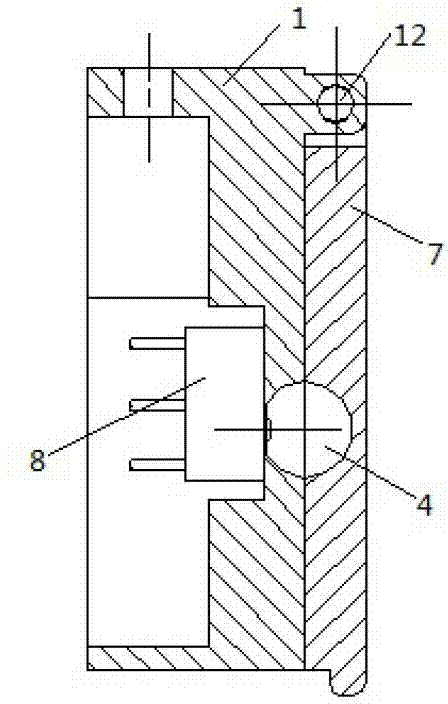

[0016] A liquid shortage monitor for a transparent pipeline, comprising a base 1 on which a photosensitive tube bracket is fixed, a groove-type photoelectric sensor is embedded in the photosensitive tube bracket, a groove is arranged on the photosensitive tube bracket, a perfusion tube 4 is placed in the groove, and the base 1, the left and right micro switches 8 and 9 are respectively fixed at the two ends of the perfusion pipe 4, such as figure 2 shown. The left and right microswitches 8 and 9 are used to detect whether the perfusion tube 4 is put into the monitor, so as to prevent the false detection phenomenon that the perfusion tube 4 is not put into the monitor.

[0017] like figure 2 , 3 , 4, the first and second photosensitive tube supports 2 and 3 are fixed at the central position of the base 1, and the first and second photosensitive tube supports 2 and 3 are all installed on the base 1 by screws 13. The first photosensitive tube The first groove photoelectric s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com