Polymeric-inorganic nanoparticle compositions, manufacturing process thereof and their use as lubricant additives

A technology of inorganic nanoparticles and polymers, which is applied in the field of improving tribological properties, improving extreme pressure performance and friction reduction rate on metal parts, and can solve problems such as engine parts and bearing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

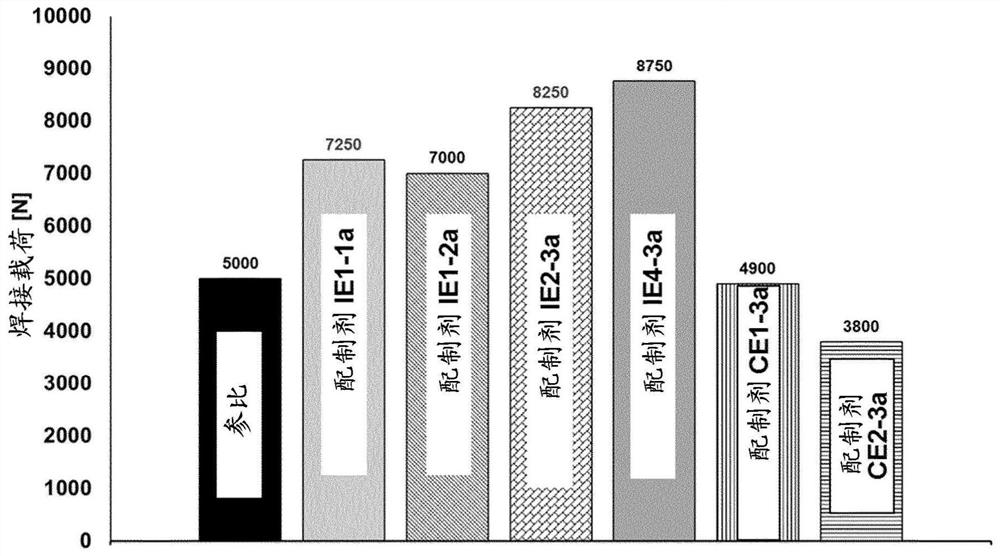

Examples

preparation example Construction

[0179] Preparation of polymer compound (B)

[0180] According to the present invention, above-mentioned polymer can be prepared according to the method comprising the following steps:

[0181] (a) providing a monomer composition as described above; and

[0182] (b) initiating free radical polymerization in the monomer composition.

[0183] Standard free-radical polymerization is described in detail in Ullmann's Encyclopedia of Industrial Chemistry, Sixth Edition, among others. In general, polymerization initiators and optionally chain transfer agents are used for this purpose.

[0184] The polymerization can be carried out under standard pressure, reduced pressure or elevated pressure. The polymerization temperature is also not critical. Generally, however, it is in the range of -20 to 200°C, preferably 50 to 150°C and more preferably 80 to 130°C.

[0185] Polymerization step (b) can be carried out with or without dilution in oil. If diluted, the amount of the monomer ...

Embodiment approach

[0198] According to a preferred embodiment of the present invention, said polymer-inorganic nanoparticle composition is obtainable by grinding a mixture comprising one or more intercalation compounds (A) and one or more polymer compounds (B),

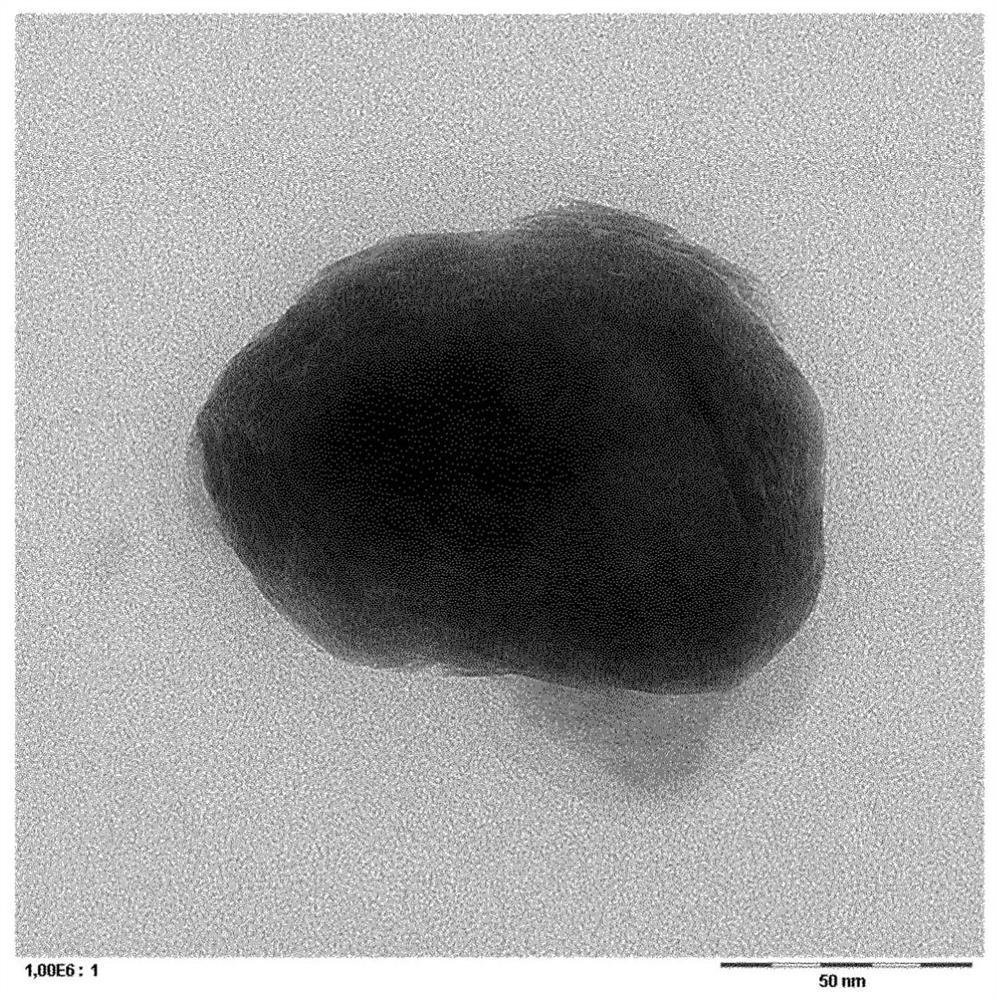

[0199] Wherein the intercalation compound (A) is a nanostructured compound comprising a multilayer fullerene-like nanostructure consisting of metal chalcogenides each having the molecular formula MX 2 A multilayer composition of (M=W and X=S), which preferably has a spherical shape,

[0200] Wherein said one or more polymer compounds (B) can be obtained by polymerizing the following monomer composition comprising:

[0201] a) 1 to 60% by weight, preferably 2 to 50% by weight, more preferably 2 to 40% by weight, most preferably 3 to 35% by weight of said one or more polymer compounds (B) or multiple functional monomers as component a); and

[0202] b) 10 to 99% by weight, preferably 20 to 98% by weight, more preferably 30 to 98% by we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com