Interface optimization type perovskite solar cell and preparation method thereof

A technology for solar cell and interface optimization, applied in the field of solar cells, can solve the problems of harsh conditions and high optimization cost, and achieve the effects of good stability, expansion of device material selection space, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

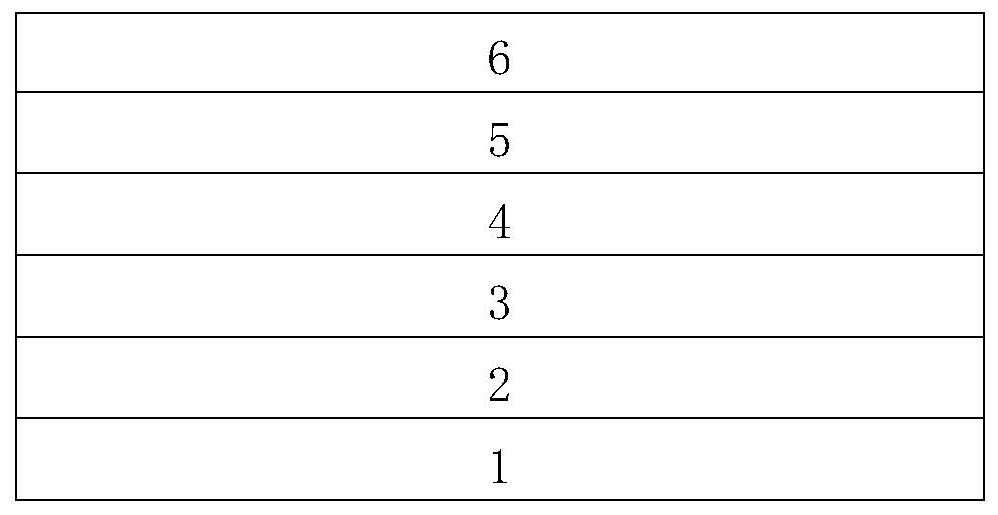

[0029] Example 1 An interface-optimized perovskite solar cell, such as figure 1 As shown, from bottom to top are conductive glass substrate 1 , electron transport layer 2 , perovskite functional layer 3 , hole transport layer 4 , hole modification layer 5 and cathode electrode 6 .

[0030] The material of the hole transport layer 4 is SPIRO-OMeTAD; the material of the hole modification layer 5 is HAT-CN; the cathode electrode 6 is an Ag electrode; the material of the conductive glass substrate 1 is tin oxide doped with fluorine; the electron transport layer 2 The material is TiO 2 ; The material of the perovskite functional layer 3 is CH 3 NH 3 PB 3.

[0031] The thickness of the conductive glass substrate 1 is 3mm; the thickness of the electron transport layer 2 is 100nm; the thickness of the perovskite functional layer 3 is 300nm; the thickness of the hole transport layer 4 is 200nm; the thickness of the hole modification layer 5 is 10nm; The thickness of the cathode el...

Embodiment 2

[0039] Embodiment 2 is an interface-optimized perovskite solar cell and its preparation method. The difference from Embodiment 1 is that the hole modification layer 5 of this embodiment has a thickness of 5 nm.

Embodiment 3

[0040] Embodiment 3 is an interface-optimized perovskite solar cell and its preparation method. The difference from Embodiment 1 is that the hole modification layer 5 of this embodiment has a thickness of 15 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com