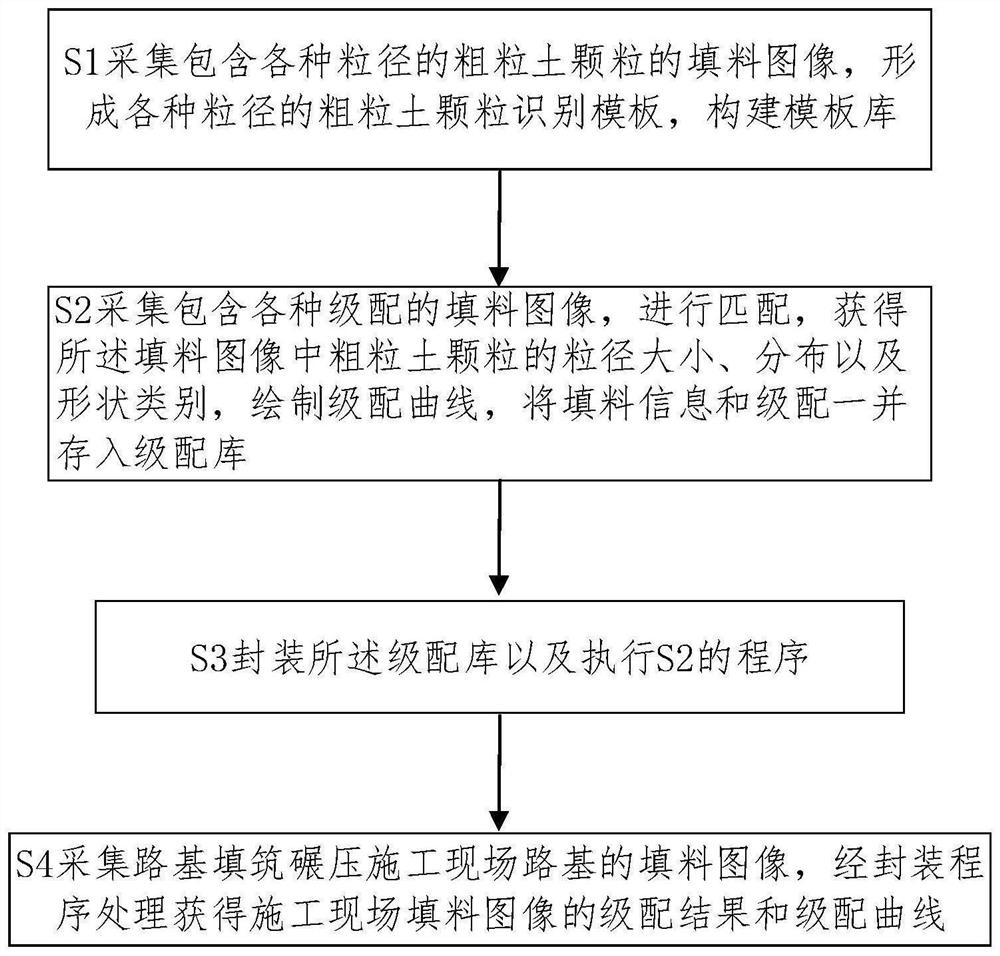

Coarse-grained soil filler grading automatic identification method based on image matching and application system

A filling grading and automatic identification technology, applied in character and pattern recognition, instruments, biological neural network models, etc., can solve the problems of disturbing the site state, manual intervention, time-consuming, etc., and achieve strong environmental adaptability and high degree of automation , high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in combination with specific embodiments and with reference to the accompanying drawings. It should be understood that these descriptions are exemplary only, and are not intended to limit the scope of the present invention. Also, in the following description, descriptions of well-known structures and techniques are omitted to avoid unnecessarily obscuring the concept of the present invention.

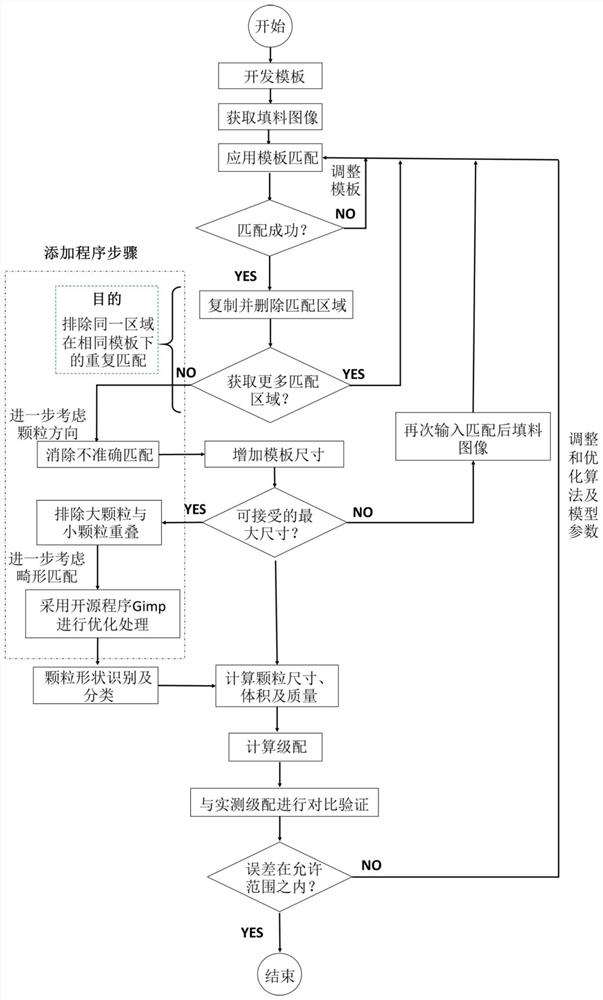

[0043] The invention relates to an image-matching-based automatic recognition method for the gradation of coarse-grained soil fillers, which is used for evaluating the size and mass distribution (ie, gradation) of all particles of the coarse-grained soil fillers. Such as Figure 4 Shown is a common gradation curve to describe the gradation, where the abscissa is the sieve size (or particle size), and the ordinate is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com