Construction method of spherical crown-shaped space truss structure roof tile

A network frame structure and construction method technology, which is applied in the direction of roofing, roof engineering tools, building structures, etc., can solve the problems of difficult construction of spherical crown-shaped grid roof tiles, difficulty in ensuring installation accuracy, etc., and achieve hoisting The effect of small mechanical requirements, enhanced safety, and guaranteed installation accuracy and installation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

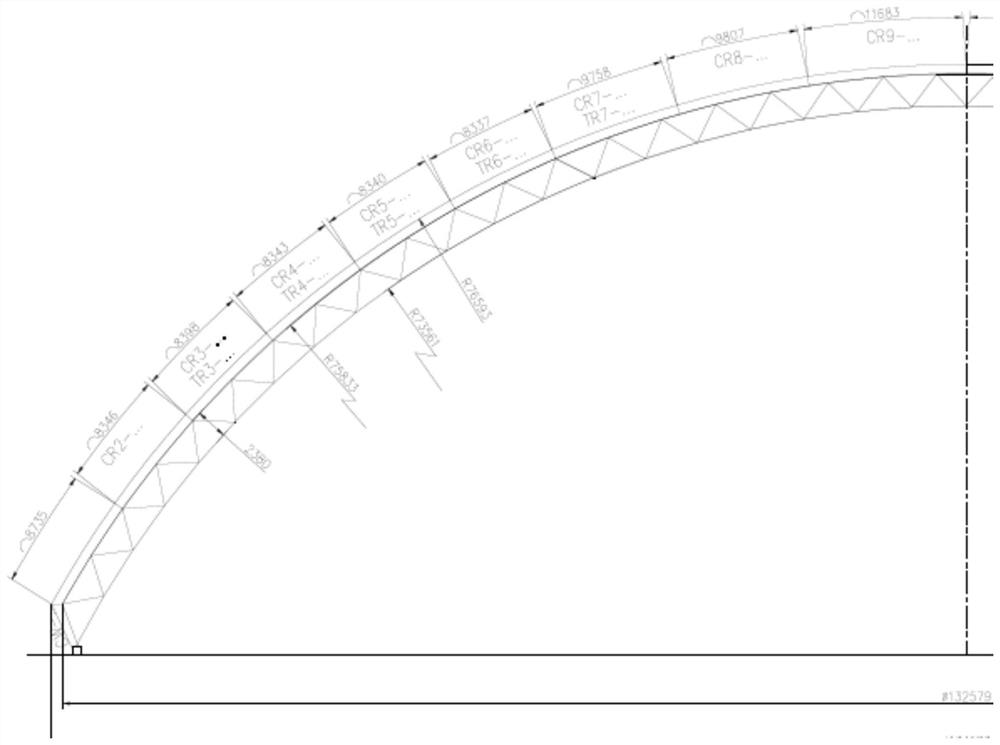

[0039] Below in conjunction with accompanying drawing, structure and working process of the present invention will be further described.

[0040] The construction method of the roof tile of the spherical crown grid structure includes the following steps:

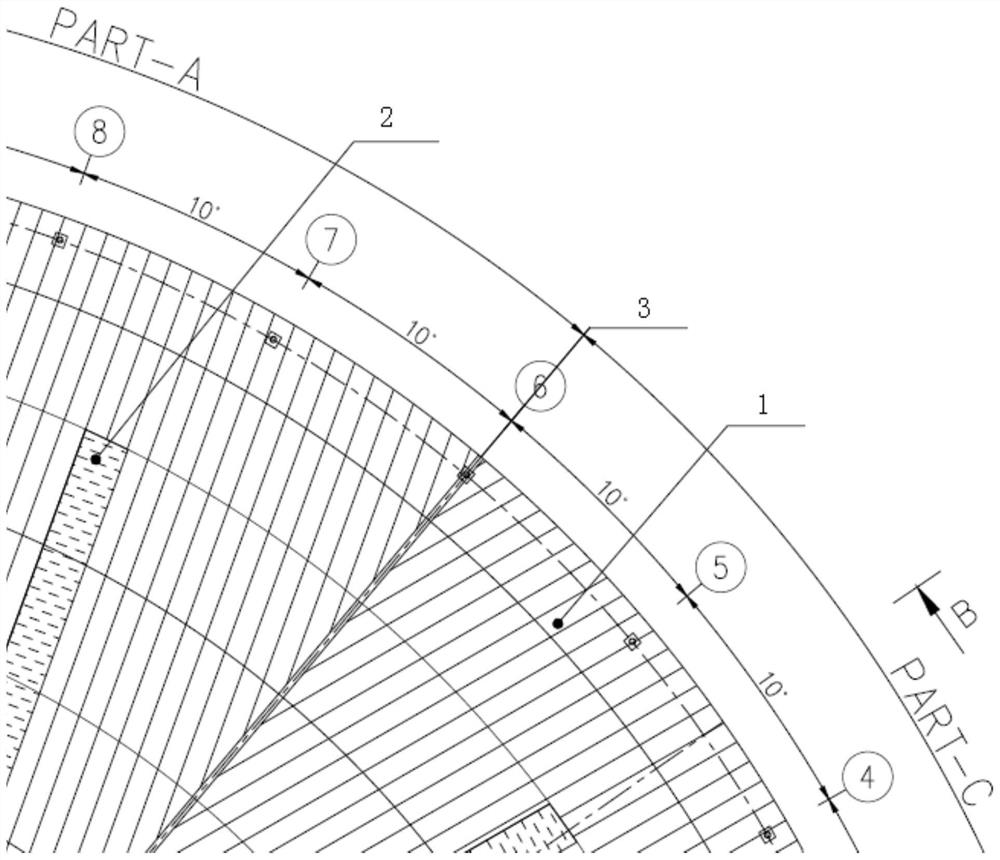

[0041] Step 1. According to the height and span of the assembled spherical crown-shaped grid structure, divide its surface into multiple sectors, and then divide each sector into multiple roof tile construction areas according to the building height. Each construction area is divided into multi-layer;

[0042] Step 2. Locate with the grid axis where the central area of each sector is located as the reference line;

[0043] Step 3. Follow the steps below to lay the roof tiles in the construction area at the bottom of the first sector:

[0044] Step 3.1. Lay the first roof tile of the bottom layer on both sides of the reference line and fix them. The reference line and the first roof tile on both sides form a guide line. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com