Air valve material for automobile electronic vehicle stability control system, and preparation method of air valve

A technology of stability control and automotive electronics, applied in the field of automotive materials, can solve problems such as high hardness, demanding valve performance, and no suppliers, achieve excellent processing performance, ensure tear resistance, and save foreign exchange.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

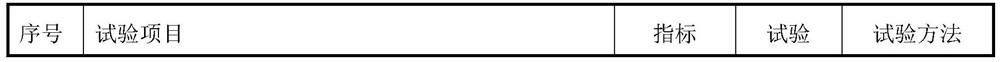

Image

Examples

Embodiment 1

[0035] A kind of air valve material for automotive electronic vehicle stability control system that the present invention proposes, its raw material comprises by weight parts:

[0036] EPDM rubber: 100 parts

[0037] Thermoplastic Elastomer: 10 parts

[0038] Indirect zinc oxide: 5 parts

[0039] High wear-resistant furnace black: 70 parts

[0040] White carbon black: 5 parts

[0041] Processing aid: 3 parts

[0042] Antiager TMQ: 1 part

[0043] Peroxide DCP curing agent: 2.5 parts

[0044] Insoluble sulfur: 0.1 part;

[0045] Wherein, the EPDM rubber is Arlanxeo EPDM rubber; the thermoplastic elastomer is JSR RB series thermoplastic elastomer; the high wear-resistant furnace black is Shanghai Cabot high wear-resistant furnace black; The white carbon black is Belgian Solvay white carbon black: the processing aid is the WB series processing aid of struktol in the United States: the peroxide DCP curing agent is Kunshan Yatman peroxide DCP curing agent; The insoluble sul...

Embodiment 2

[0056] A kind of air valve material for automotive electronic vehicle stability control system that the present invention proposes, its raw material comprises by weight parts:

[0057] ARLANXEO EPDM: 100 parts

[0058] JSR RB series thermoplastic elastomer: 5 parts

[0059] Indirect zinc oxide: 3 parts

[0060] Shanghai Cabot High Abrasion Furnace Black: 50 parts

[0061] Belgian Solvay silica: 15 parts

[0062] American struktol WB series processing aids: 1 part

[0063] Antiager TMQ: 2 parts

[0064] Kunshan Atman peroxide DCP vulcanizing agent: 3.5 parts

[0065] Kunshan Yatman insoluble sulfur: 0.2 parts.

[0066] The method for preparing the air valve according to the above formula may further comprise the steps:

[0067] S1, the first mixing: put other raw material components except Kunshan Atman peroxide DCP vulcanizing agent and Kunshan Atman insoluble sulfur in the internal mixer for the first internal mixing according to the parts by weight. The first interna...

Embodiment 3

[0075] A kind of air valve material for automotive electronic vehicle stability control system that the present invention proposes, its raw material comprises by weight parts:

[0076] ARLANXEO EPDM: 100 parts

[0077] JSR RB series thermoplastic elastomer: 7 parts

[0078] Indirect zinc oxide: 5 parts

[0079] Shanghai Cabot High Abrasion Furnace Black: 60 parts

[0080] Belgian Solvay silica: 10 parts

[0081] American struktol WB series processing aids: 2 parts

[0082] Antiager TMQ: 1 part

[0083] Kunshan Atman peroxide DCP vulcanizing agent: 3 parts

[0084] Kunshan Yatman insoluble sulfur: 0.15 parts.

[0085] The method for preparing the air valve according to the above formula may further comprise the steps:

[0086] S1, the first mixing: put other raw material components except Kunshan Atman peroxide DCP vulcanizing agent and Kunshan Atman insoluble sulfur in the internal mixer for the first internal mixing according to the parts by weight. The first internal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com