Preparation method of inorganic micro-powder/PBAT full-degradable composite film

A technology of inorganic micropowder and composite film, applied in the field of packaging materials, can solve the problems of easy adhesion, high cost, etc., and achieve the effect of simple process, low price, and improvement of the blown film production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

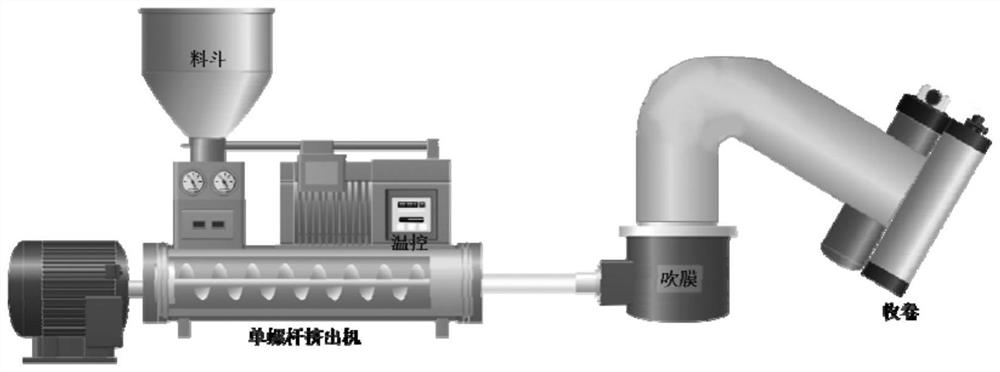

[0026] like figure 1 method, the 5000 mesh calcium carbonate powder (CaCO 3 , derived from limestone) is added to the hopper, blended with PBAT masterbatch, the amount of calcium carbonate micropowder is 25% of PBAT masterbatch, and fully mixed evenly, the blended raw materials are produced through screw extruder and blown film process Composite film , and winding, the temperature of each zone of the screw extruder is between 120 and 150 °C, the thickness of the composite film is 50 μm, and the width is 0.01 m.

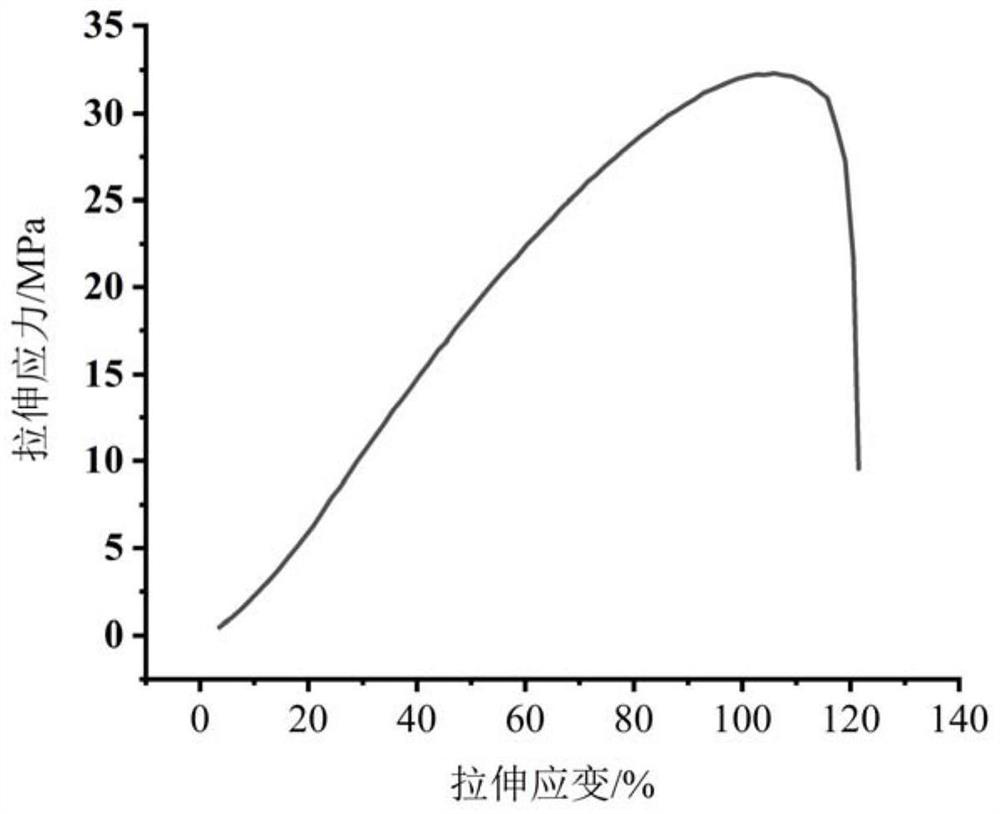

[0027] Narrow and wide composite films can be used in the outer packaging of disposable straws and chopsticks, etc., and wider ones can be used in various specifications of shopping bags, packaging bags, takeaway bags, etc. figure 2 The mechanical performance test of the calcium carbonate / PBAT composite film with a relative content of 25% shows a strength of 32Mpa and an elongation at break of 110%, and the performance is very excellent.

Embodiment 2

[0029] Add 500 mesh mica powder (derived from mica stone) to the hopper, blend with PBAT masterbatch, the amount of silicon micropowder is 0.5%, 5%, 10% of PBAT masterbatch, and fully mix evenly; the blended raw materials are passed through The composite film is produced by the film blowing process and wound. The thickness of the obtained composite film is 10-50 μm and the width is 0.2-1 m. The wound composite film can be used as an agricultural mulch film. The wound composite film is passed through the bag-making process Fully biodegradable bags of different specifications are produced.

Embodiment 3

[0031] Add 2000-mesh talc powder and quartz powder to the hopper at a ratio of 1:1, and blend with PBAT masterbatch, where the powder is 50% of the PBAT masterbatch, and mix well, and the blended raw materials are produced by blown film process Composite film, and winding, the temperature of each zone of the screw extruder is between 120 and 150°C, the thickness of the composite film is 5-30μm, and the width is 0.15-0.35m, and the wound composite film is produced by bag-making process Fully biodegradable bags of different specifications.

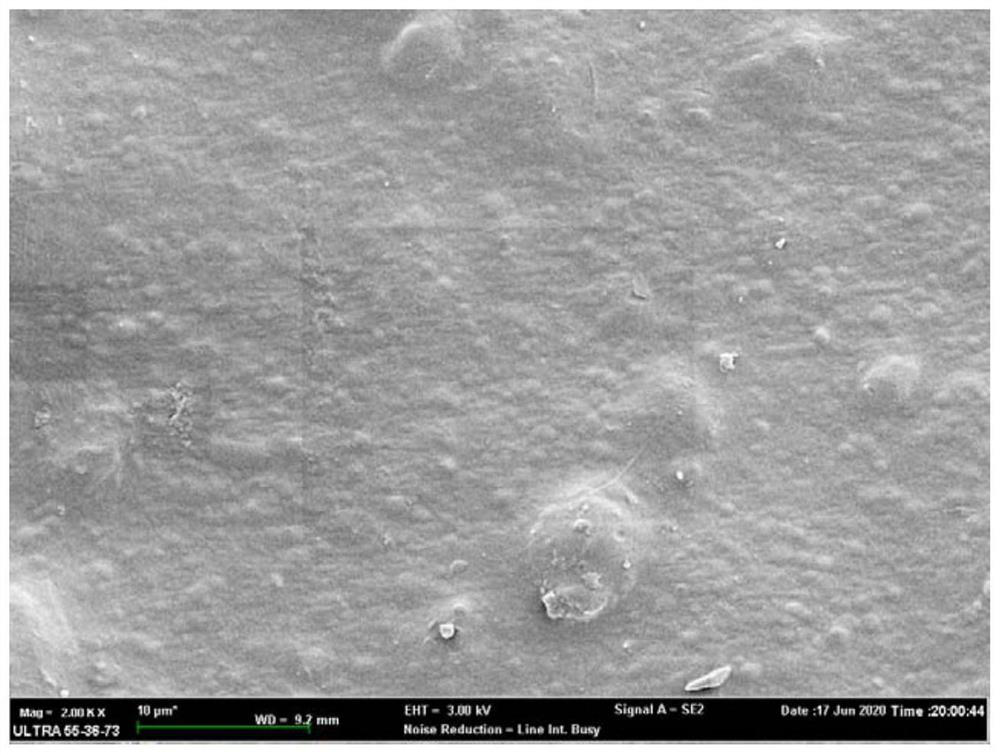

[0032] image 3 It shows the microscopic morphology of the talc powder and quartz powder (1:1) / PBAT composite film with a relative content of 50%, which shows good dispersion, and its performance meets the application requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com