High-stability environment-friendly carbon nanotube water dispersing liquid and preparation method thereof

A technology of carbon nanotubes and high stability, which is applied in the field of preparation of carbon nanotube dispersion stabilizers, can solve the problems of easy aggregation of carbon nanotubes, low dispersion concentration, environmental pollution, etc., to improve hydrophobicity, increase adsorption, The effect of solving environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] In terms of mass fraction, 1 part of multi-walled carbon nanotubes (CNT-E3010, Zhongshan Carnet Plastic Co., Ltd.), 10 parts of sodium lignosulfonate (NF-2, Yanbian Shixian Shuanglu Industrial Co., Ltd., ≤12%, inorganic salt content ≤3.0% (Na 2 SO 4 )), 0.2 parts of deionized water, and grind for 3 hours by manual grinding. After grinding, add 400 parts of deionized water to dilute, use 0.1M dilute hydrochloric acid or 0.1M dilute NaOH solution to adjust the pH to 7, add 5 parts of dodecane Sodium phenyl sulfonate was ultrasonically dispersed for 0.5 h to obtain a stable dispersion of carbon nanotubes in water.

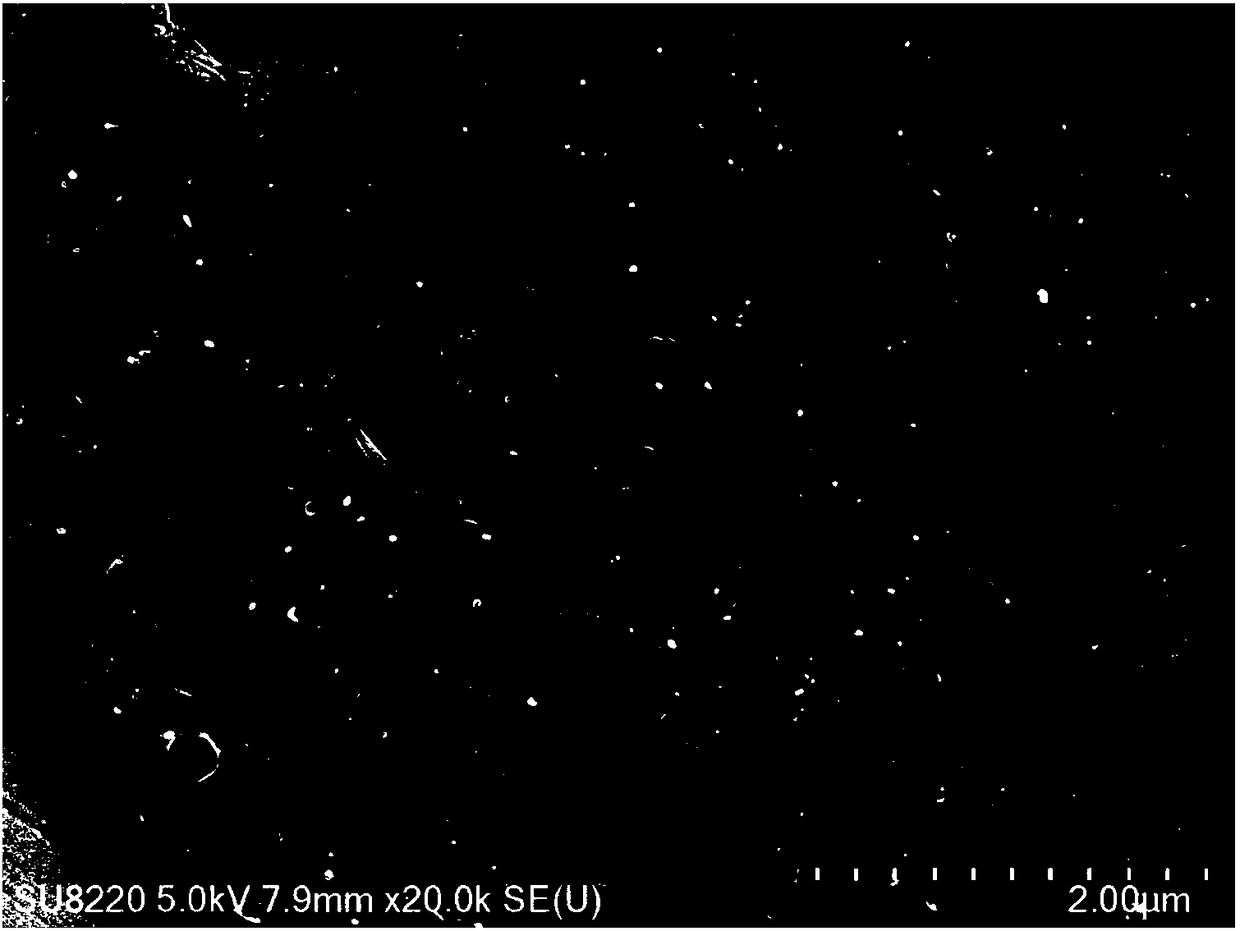

[0041] figure 1 It is a high-magnification scanning electron microscope picture of the highly stable and environmentally friendly carbon nanotube aqueous dispersion obtained in Example 1 using a scanning electron microscope (FE-SEM, SU-8200, Japan). It can be seen from the figure that the carbon nanotubes are uniformly dispersed and are in a single-layer fla...

Embodiment 2

[0046] In terms of mass fraction, 1 part of multi-walled carbon nanotubes (CNT-E3010, Zhongshan Carnet Plastic Co., Ltd.), 7 parts of calcium lignosulfonate (M-9, Yanbian Shixian Shuanglu Industrial Co., Ltd., ≤12%, calcium and magnesium particle content ≤1.5%), mix with 0.4 parts of deionized water, use a ball mill to grind for 3 hours, add 500 parts of deionized water to dilute after grinding, adjust the pH to 8, add 5 parts of sodium lauryl sulfate Ultrasonic dispersion was carried out for 1 h to obtain a stable dispersion of carbon nanotubes in water.

[0047] The obtained aqueous dispersion of carbon nanotubes had an apparent color of dark black and a concentration of 2.0 g / L. After measurement, the Zeta potential of the aqueous dispersion was -54.2mV, the hydrated particle size was 600.2nm, and no precipitation was found by centrifugation at 5000r / min for 15min. It is proved that the aqueous dispersion of carbon nanotubes has good stability.

[0048] Compounded with 24...

Embodiment 3

[0050] In terms of mass fraction, 2 parts of single-walled carbon nanotubes (TNST, Zhongke Times Nano), 10 parts of sodium lignosulfonate (NF-2, Yanbian Shixian Shuanglu Industrial Co., Ltd., reducing content ≤ 12%, inorganic Salt content ≤ 3.0% (Na2SO4)), mixed with 0.6 parts of deionized water, using a ball mill to grind for 2 hours, after grinding, add 500 parts of deionized water to dilute, adjust the pH to 7, add 10 parts of dodecyl hydroxy sultaine Ultrasonic dispersion was carried out for 1 h to obtain a stable dispersion of carbon nanotubes in water.

[0051] The obtained aqueous dispersion of carbon nanotubes had an apparent color of dark black and a concentration of 4.0 g / L. After measurement, the Zeta potential of the aqueous dispersion was -59.2mV, and the hydrated particle size was 590.8nm. No precipitation was found by centrifugation at 5000r / min for 15min. It is proved that the aqueous dispersion of carbon nanotubes has good stability.

[0052] Compounded with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com