Industrial composite paper board and preparing technology thereof

A preparation process and paperboard technology, applied in the direction of machining/deformation, etc., can solve the problems of dislocation in the conveying process, dislocation in the pressing process of the base paper, and impact on the quality of the composite paperboard, and achieve the effect of reducing the burden.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

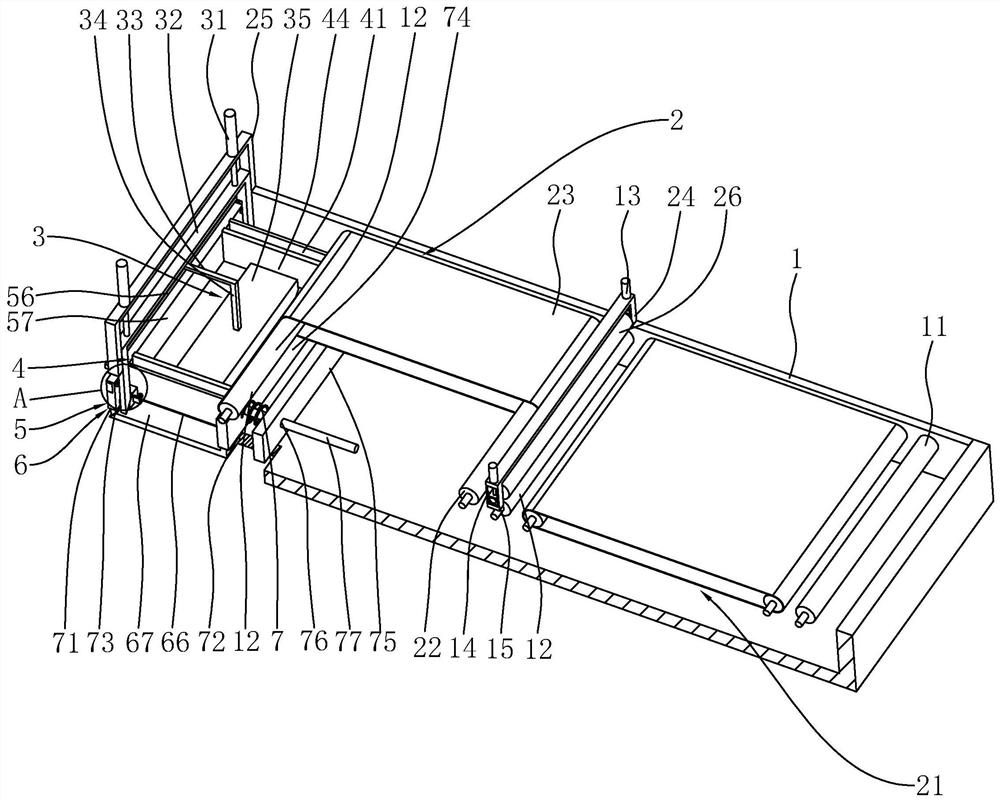

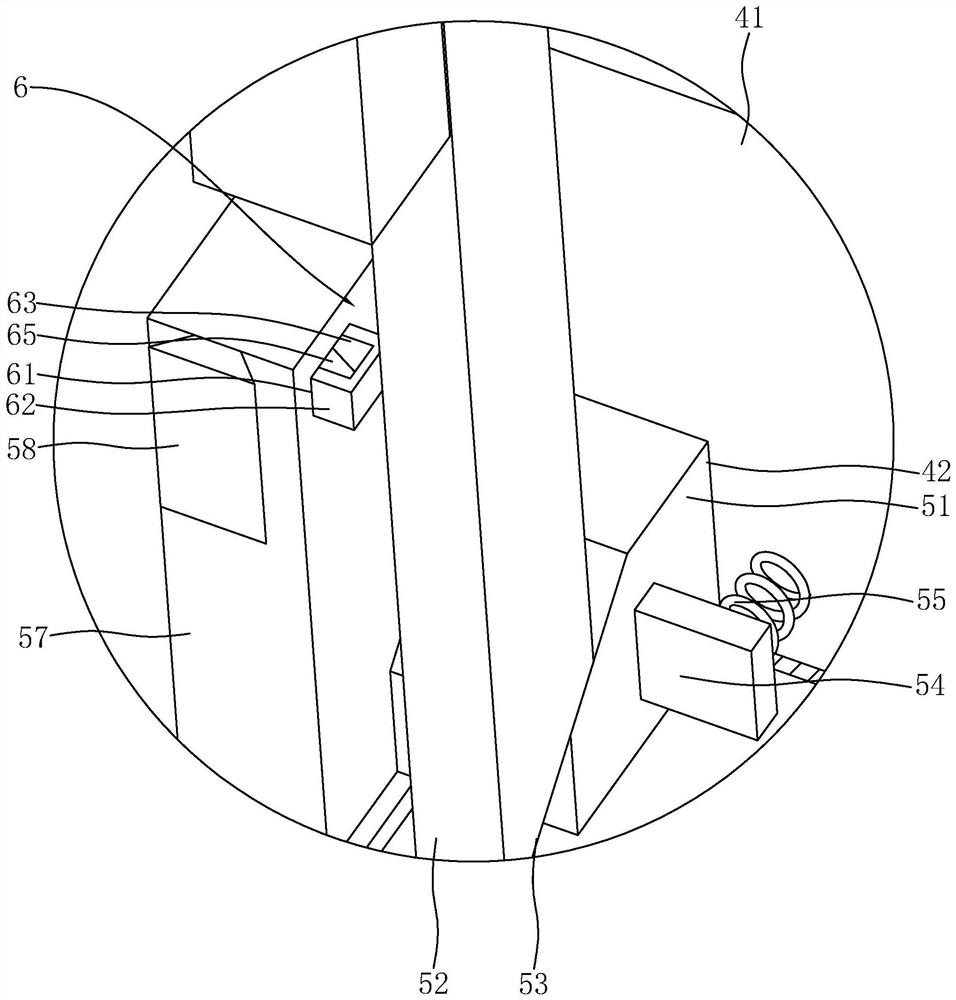

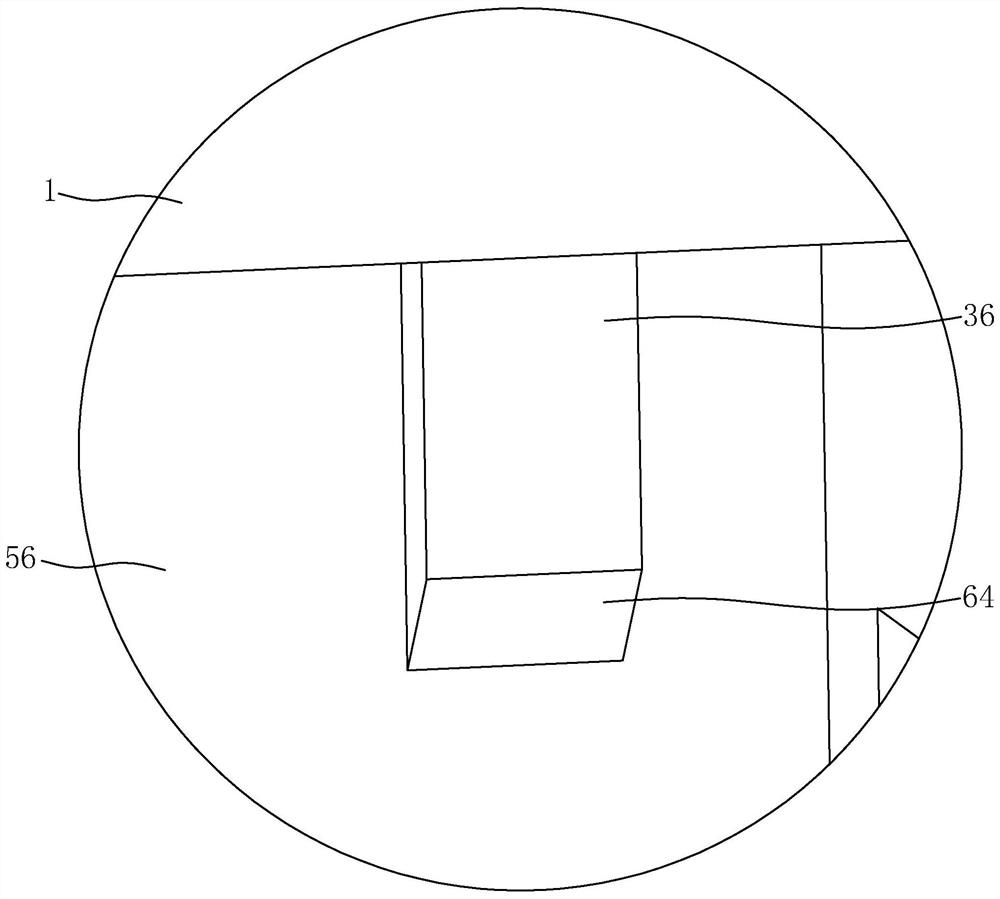

[0040] Embodiment 1: a kind of paper supporting machine, such as figure 1 As shown, it includes a roller bed 1, a heating roller 11 and a second transmission roller 12 rotatably installed on the opposite inner side of the roller bed 1, and a first transmission assembly 2 and a second transmission assembly 21 arranged in the roller bed 1 and used to transport base paper ; The second transmission assembly 21 has the same structure as the first transmission assembly 2 . The first transmission assembly 2 includes two first transmission rollers 22 rotatably installed on the opposite inner sides of the roller bed 1 and a conveyor belt 23 for linking the two first transmission rollers 22 . The first transmission assembly 2 and the second transmission assembly 21 are arranged on two sides of the second transmission roller 12 respectively; the heating roller 11 is arranged on the side of the second transmission assembly 21 away from the second transmission roller 12 . The top of the r...

Embodiment 2

[0057] Embodiment 2: a kind of preparation technology of industrial composite cardboard, comprises the steps:

[0058] S1. Loading: Select high-gloss paper as the base paper, and put the base paper on the paper support machine in turn. Three adjacent base papers on the paper support machine form a group, and the interval between two adjacent base paper groups on the paper support machine is 70cm. In each base paper group, the interval between two adjacent base papers on the paper support machine is 18cm.

[0059] S2. Preheat the base paper: set the heating temperature of the heating roller 11 to 45° C., and the base paper moves into the second transmission assembly 21 after being heated by the heating roller 11 .

[0060] S3. Apply glue to the preheated base paper: the base paper moves to the top of the second transmission roller 12, start the second cylinder 31 to drive the glue roller 26 to move downward, apply glue to the base paper, and set the coating speed of the glue rol...

Embodiment 3

[0063] Embodiment 3: a kind of preparation technology of industrial composite cardboard, comprises the steps:

[0064] S1. Loading: Select high-gloss paper as the base paper, and put the base paper on the paper support machine in turn. Three adjacent base papers on the paper support machine form a group, and the interval between two adjacent base paper groups on the paper support machine is 80cm. In each base paper group, the interval between two adjacent base papers on the paper support machine is 15-20cm.

[0065] S2. Preheat the base paper: set the heating temperature of the heating roller 11 to 50° C., and the base paper moves into the second transmission assembly 21 after being heated by the heating roller 11 .

[0066] S3. Apply glue to the preheated base paper: the base paper moves to the top of the second transmission roller 12, start the second cylinder 31 to drive the glue roller 26 to move downward, apply glue to the base paper, and set the coating speed of the glu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com