Preparation method of phosphate radical adsorbent based on 3D rGO/zirconium dioxide composite material

A composite material and zirconium dioxide technology, applied in the field of environmental pollutant treatment, can solve problems such as balance imbalance and toxicity, and achieve the effects of low cost, simple preparation and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] GO was prepared by a conventional method, and a 3 mg / mL dispersion was prepared with deionized water as needed.

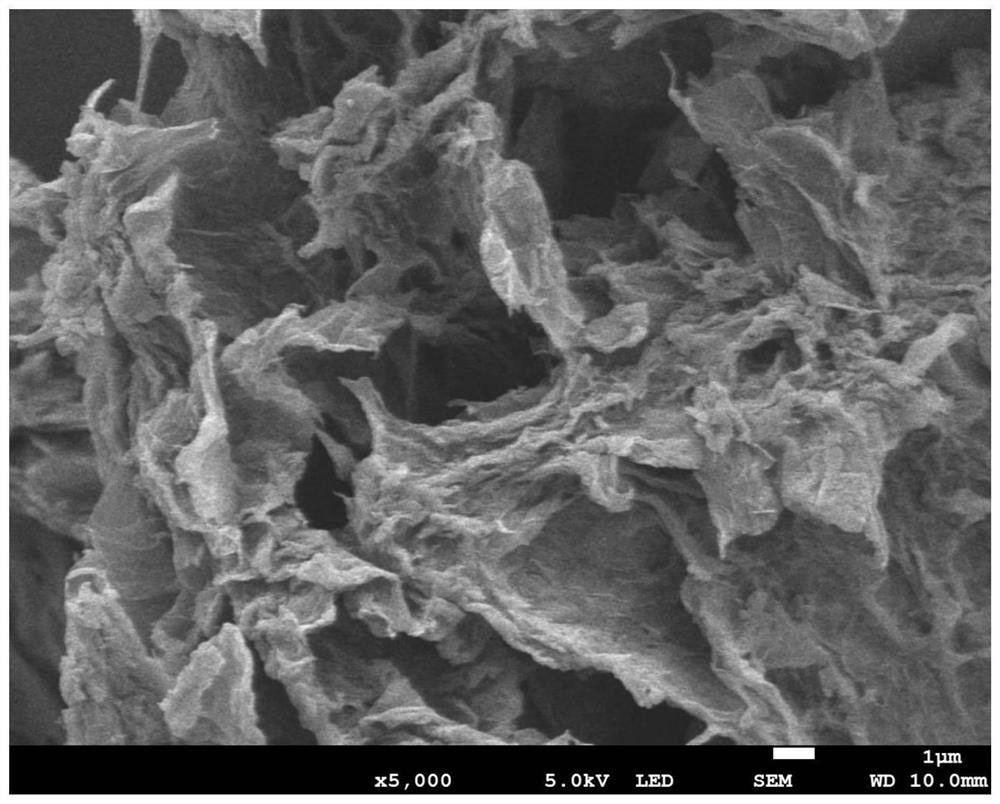

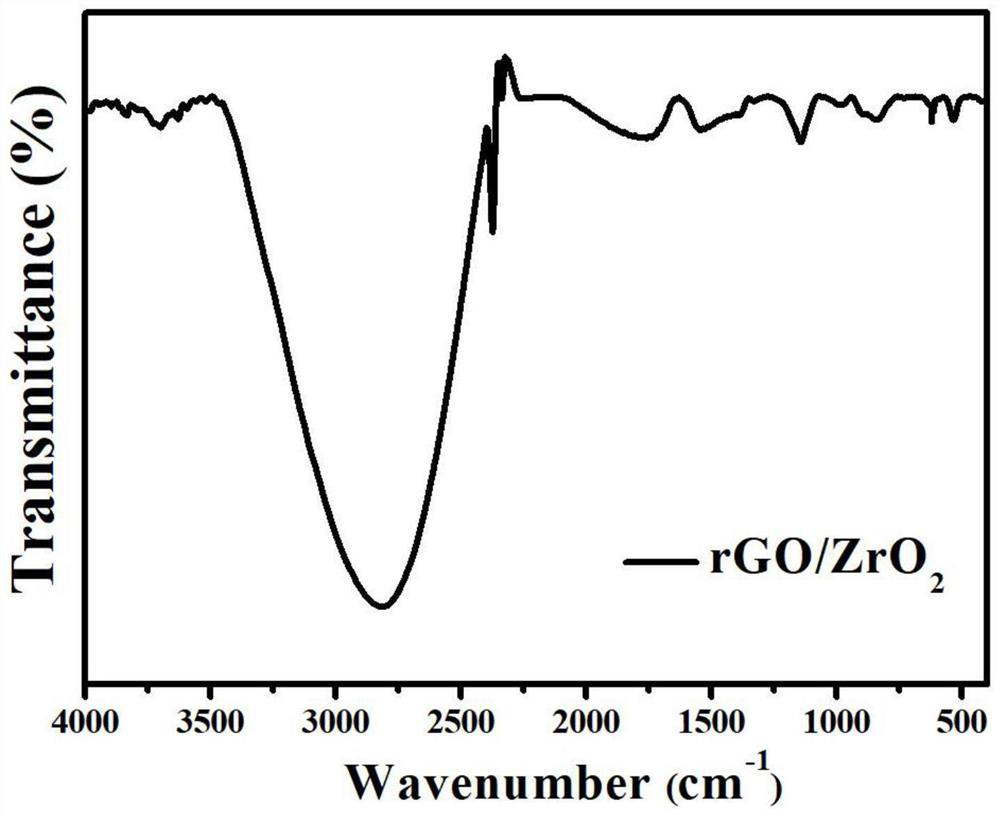

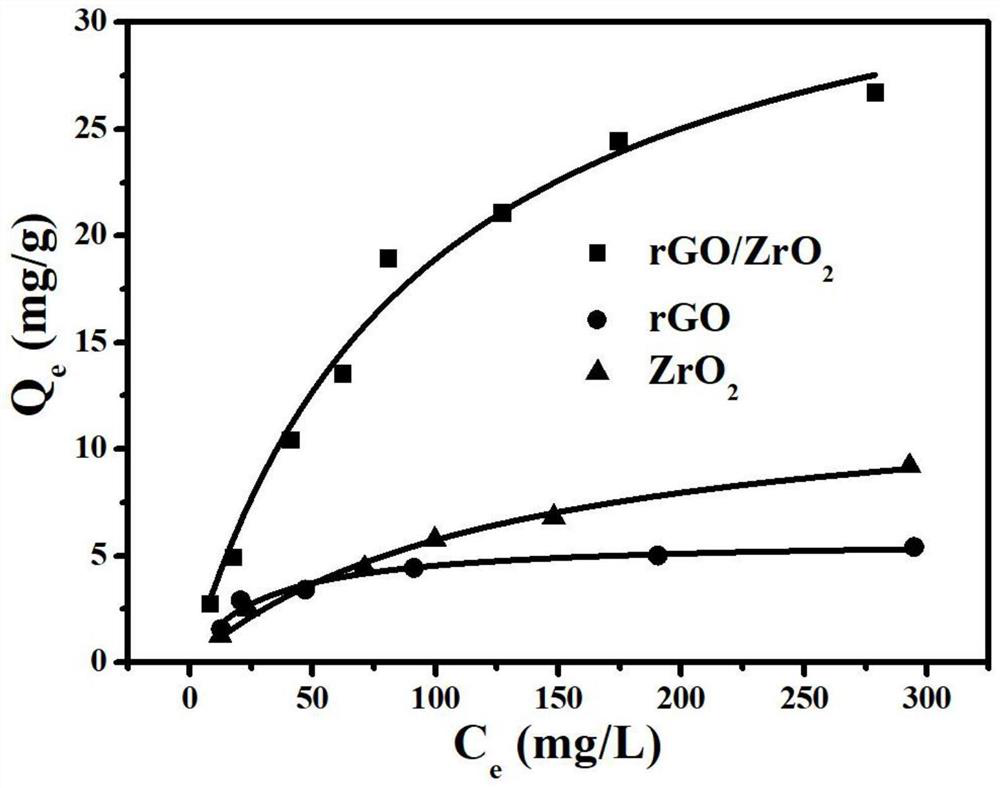

[0019] 50mg of ZrOCl 2 ·8H 2 O and 50mg of glutamic acid were dissolved in 1mL of deionized water and sonicated for 10min. While stirring, add the above mixed solution and 5 mL of 3 mg / mL GO dispersion into 30 mL of ethylene glycol. The above mixed solution was transferred to a polytetrafluoroethylene reactor, and hydrothermally reacted at 180°C for 6 hours. The reacted material was repeatedly washed with deionized water to remove impurities, and finally freeze-dried to obtain the final product 3D rGO / ZrO 2 .

Embodiment 2

[0021] GO was prepared by a conventional method, and a 3 mg / mL dispersion was prepared with deionized water as needed.

[0022] 30mg of ZrOCl 2 ·8H 2 O and 50mg of glutamic acid were dissolved in 1mL of deionized water and sonicated for 10min. While stirring, add the above mixed solution and 5 mL of 3 mg / mL GO dispersion into 30 mL of ethylene glycol. The above mixed solution was transferred to a polytetrafluoroethylene reactor, and hydrothermally reacted at 180°C for 6 hours. The reacted material was repeatedly washed with deionized water to remove impurities, and finally freeze-dried to obtain the final product 3D rGO / ZrO 2 .

Embodiment 3

[0024] GO was prepared by a conventional method, and a 3 mg / mL dispersion was prepared with deionized water as needed.

[0025] 40mg of ZrOCl 2 ·8H 2 O and 50mg of glutamic acid were dissolved in 1mL of deionized water and sonicated for 10min. While stirring, add the above mixed solution and 5 mL of 3 mg / mL GO dispersion into 30 mL of ethylene glycol. The above mixed solution was transferred to a polytetrafluoroethylene reactor, and hydrothermally reacted at 180°C for 6 hours. The reacted material was repeatedly washed with deionized water to remove impurities, and finally freeze-dried to obtain the final product 3D rGO / ZrO 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com