Electrochemical layer-by-layer polishing device for additive manufacturing metal tubular part

A technology of additive manufacturing and polishing device, which is applied in electrolysis process, electrolysis components, etc., can solve the problems of low selectivity of polishing area, uneven polishing, etc., and achieve the effect of avoiding excessive polishing and improving polishing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

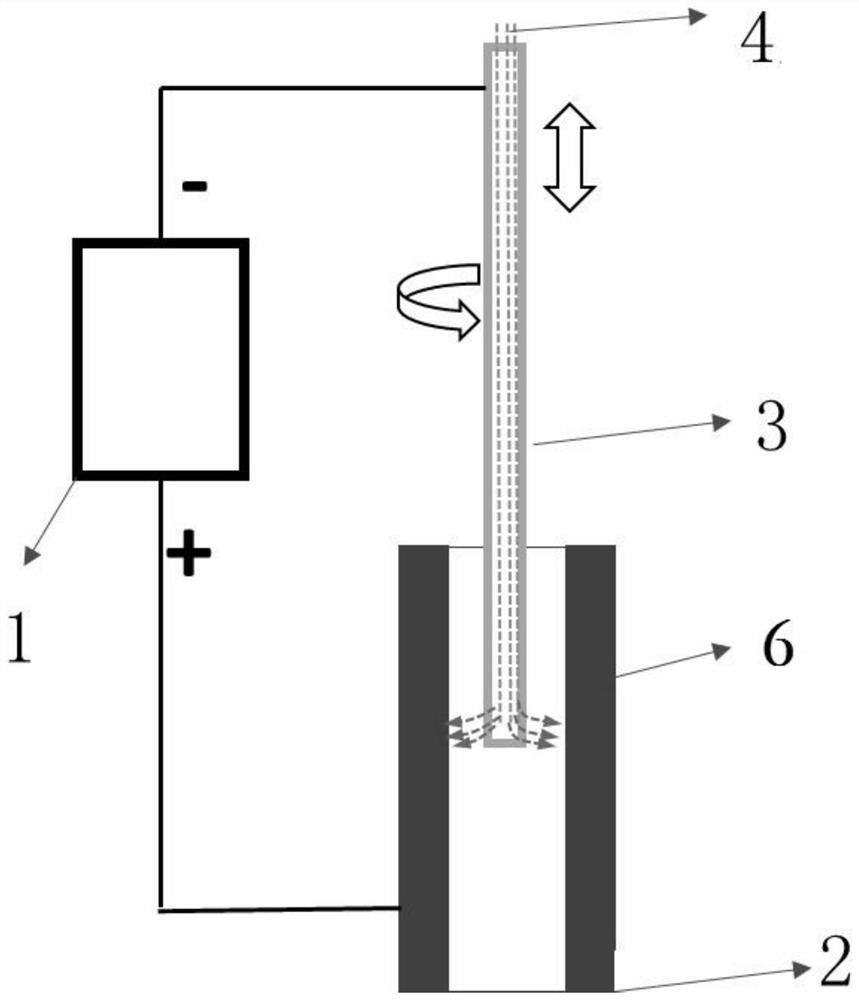

[0035] like figure 1 As shown, the electrochemical liquid spraying layer-by-layer polishing device for additively manufactured metal tubular parts provided in this embodiment includes a control drive part, a power supply 1 , a workpiece placement area 2 , an electrode 3 and a working liquid 4 . Wherein, the workpiece placement area 2 is used to place the additively manufactured metal tubular member 6 to be polished; the electrode 3 is a hollow structure, and a spray hole is opened around the lower end of the electrode 3 .

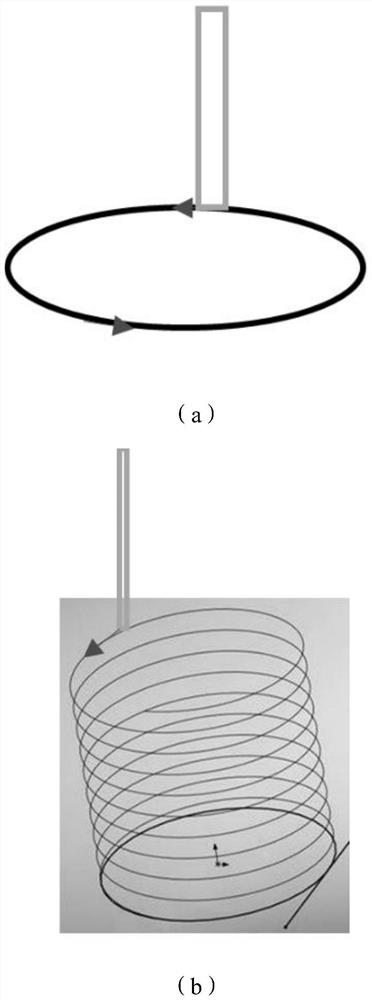

[0036]When working, the additively manufactured metal tubular part 6 to be polished is placed on the workpiece placement area 2, the electrode 3 extends into the interior of the additively manufactured metal tubular part 6, and the working fluid 4 is transferred from the storage of the working fluid 4 through an external pump. The working fluid is extracted from the working fluid tank and flows into the inside of the electrode 3; the positive pole of the po...

Embodiment 2

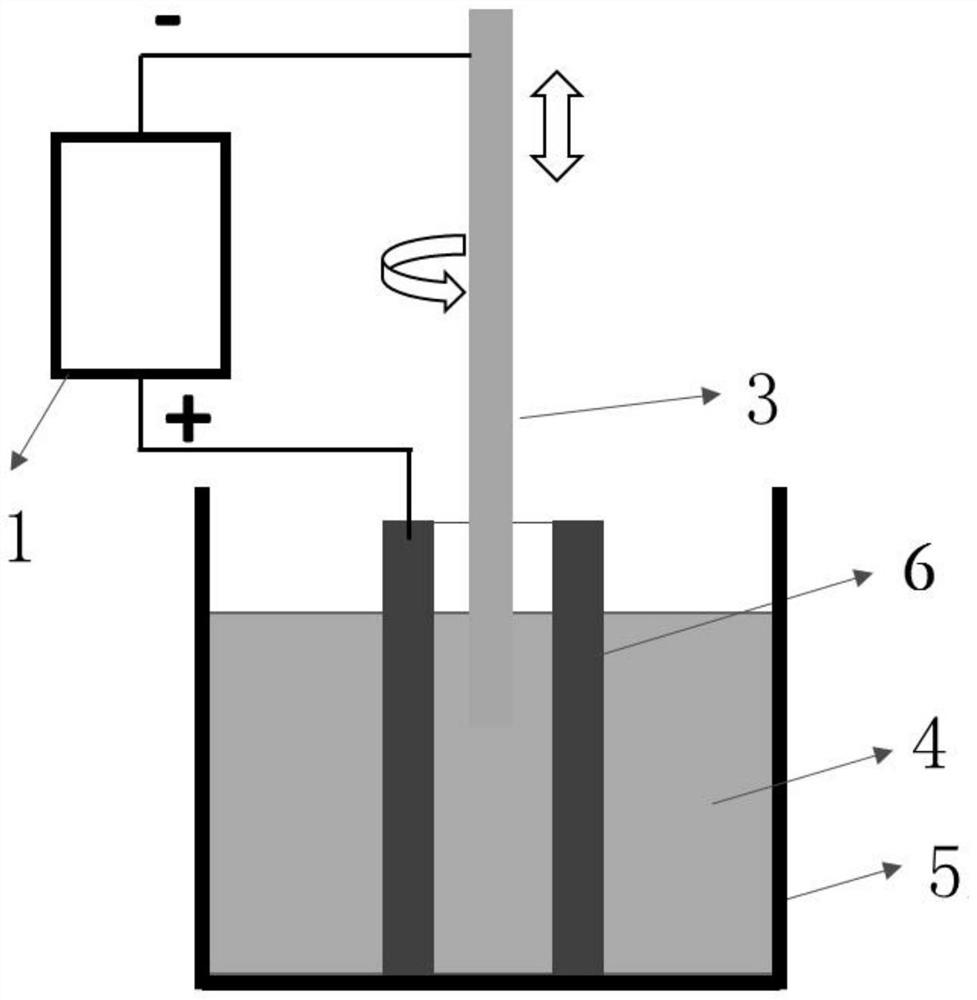

[0051] like image 3 As shown, the electrochemical immersion layer-by-layer polishing device for additively manufactured metal tubular parts provided in this embodiment includes a control drive unit, a power supply 1 , electrodes 3 , a working solution 4 and a working solution tank 5 . Wherein, the working fluid tank 5 is used for placing the additively manufactured metal tubular part 6 and the working fluid 4 to be polished.

[0052] When working, the additive manufacturing metal tubular part 6 to be polished and the working fluid 4 are placed in the working fluid tank 5, and the electrode 3 extends into the inside of the additive manufacturing metal tubular part 6; the positive electrode of the power supply 1 is connected to the additive manufacturing metal Tubular part 6, the negative pole of power supply 1 is connected to electrode 3; the control driving part is connected to electrode 3 and / or the metal tubular part 6 of additive manufacturing, and the control driving part...

Embodiment 3

[0065] In this embodiment, additive manufacturing technology is used to manufacture a stainless steel cylindrical part with an outer wall diameter of 10 mm and an inner wall diameter of 6 mm, and the device provided in Embodiment 1 is used for electrochemical polishing.

[0066]After configuring the working fluid according to the experimental data, assemble the device provided in Example 1, use the electrode as the cathode, and the stainless steel cylindrical part to be polished as the anode, and extend the electrode into the stainless steel cylindrical part; then start the control drive part and connect When the pulse power is turned on, the working fluid is sprayed onto the inner surface of the stainless steel cylindrical part through the liquid spray holes around the lower end of the electrode; finally, the driving part is controlled to control the electrode to move from top to bottom at a predetermined speed and rotate to realize layer-by-layer polishing. After a period of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Camber | aaaaa | aaaaa |

| Outer wall diameter | aaaaa | aaaaa |

| Inner wall diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com