High polymer material surface anticoagulation modification method

A polymer material, anti-coagulation technology, applied in the direction of heparin coatings, alginic acid coatings, coatings, etc., can solve the problems of low grafting rate of heparin sodium, limited surface amount of heparin sodium, and general anti-coagulation function effect, etc. The preparation method is simple and feasible, the anticoagulant effect is promoted, and the anticoagulant effect is prevented from being lasting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

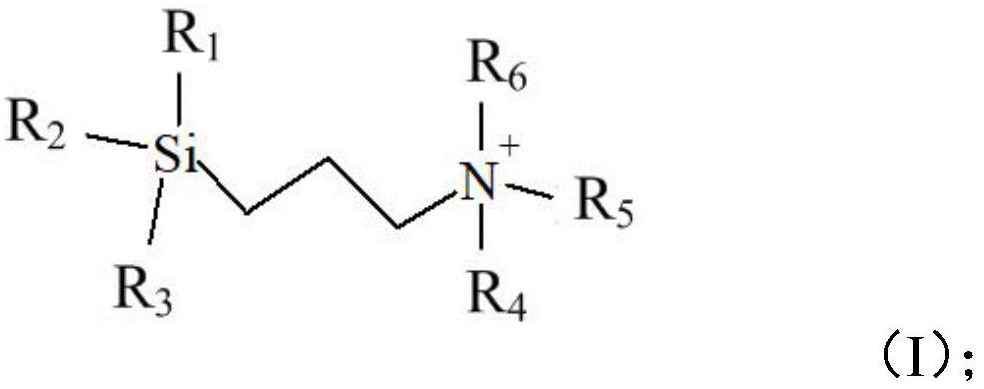

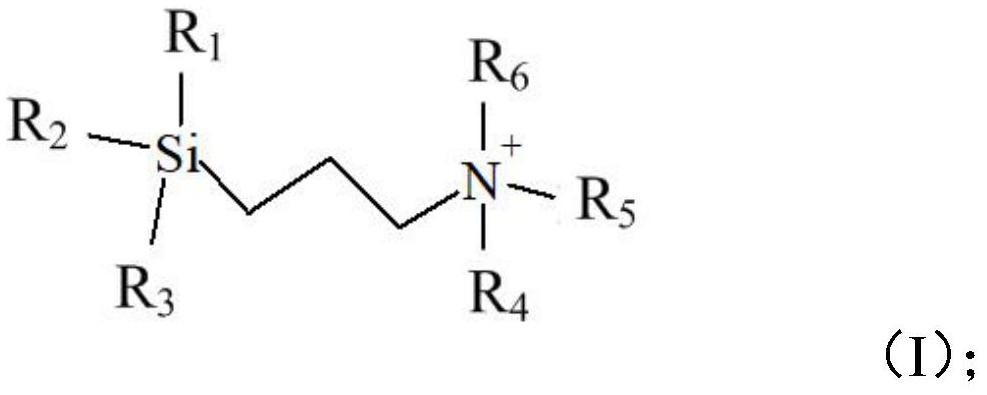

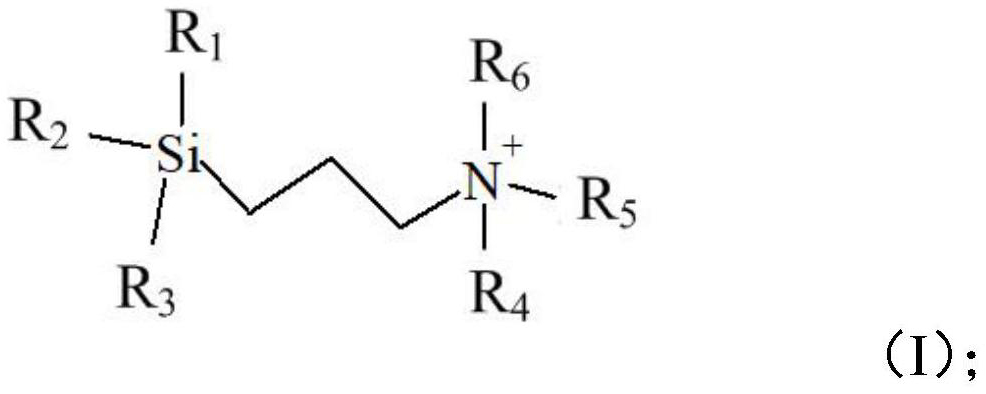

[0072] Preparation of sodium alginate and organosilicon quaternary ammonium salt charge complex: prepare respectively a concentration of 4wt% sodium alginate aqueous solution (the number average molecular weight of sodium alginate is 80000) and a concentration of 4wt% trimethyl[3-(trimethyl Oxysilyl)propyl]ammonium chloride aqueous solution, sodium alginate and trimethyl[3-(trimethoxysilyl)propyl]ammonium chloride are mixed at room temperature according to the mass ratio of 2:1, and an insoluble Precipitated in water, centrifuged, washed 3 times with water and dried to obtain charge complex of sodium alginate and trimethyl[3-(trimethoxysilyl)propyl]ammonium chloride.

[0073] Soak the poly(4-methyl-1-pentene) hollow fiber membrane in deionized water for 24 hours, dry it in a vacuum drying oven, put the dried hollow fiber membrane into the chamber of the plasma processor and fix it. Vacuum to 1Pa, pass through oxygen for surface activation. The air pressure in the cavity is 35...

Embodiment 2

[0077]Preparation of sodium alginate and organosilicon quaternary ammonium salt charge complex: prepare respectively a concentration of 1.5wt% sodium alginate aqueous solution (the number average molecular weight of sodium alginate is 10000) and a concentration of 1.5wt% dimethyltetradecane Base[3-(triethoxysilyl)propyl]ammonium chloride aqueous solution, sodium alginate and dimethyltetradecyl[3-(triethoxysilyl)propyl]ammonium chloride according to Mix at room temperature with a mass ratio of 1:1 to rapidly form a water-insoluble precipitate. After centrifugation, wash with water three times and dry to obtain sodium alginate and dimethyltetradecyl[3-(triethoxysilane base) propyl] ammonium chloride charge complex.

[0078] Soak the poly(4-methyl-1-pentene) hollow fiber membrane in deionized water for 24 hours, dry it in a vacuum drying oven, put the dried hollow fiber membrane into the chamber of the plasma processor and fix it. Vacuum to 1Pa, pass through oxygen for surface a...

Embodiment 3

[0082] Preparation of sodium alginate and organosilicon quaternary ammonium salt charge complex: prepare respectively a concentration of 2.5wt% sodium alginate aqueous solution (the number average molecular weight of sodium alginate is 30000) and a concentration of 2.5wt% dimethyl octadecane Base[3-(trimethoxysilyl)propyl]ammonium chloride aqueous solution, sodium alginate and dimethyloctadecyl[3-(trimethoxysilyl)propyl]ammonium chloride according to mass ratio Mix at room temperature at a ratio of 1:2, rapidly form a water-insoluble precipitate, centrifuge, wash 3 times with water and dry to obtain sodium alginate and dimethyloctadecyl[3-(trimethoxysilyl)propane base] ammonium chloride charge complex.

[0083] Soak the poly(4-methyl-1-pentene) hollow fiber membrane in deionized water for 24 hours, dry it in a vacuum drying oven, put the dried hollow fiber membrane into the chamber of the plasma processor and fix it. Vacuum to 1Pa, pass through oxygen for surface activation. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com