Amorphous crystal form of acetylcholine chloride and preparation method thereof

An amorphous technology of methacholine chloride, which is applied in the field of pharmaceutical crystal forms, can solve the problems of easy deliquescence of methacholine chloride and excessive water content, and achieve convenient production and quality control, strong wet stability, The effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

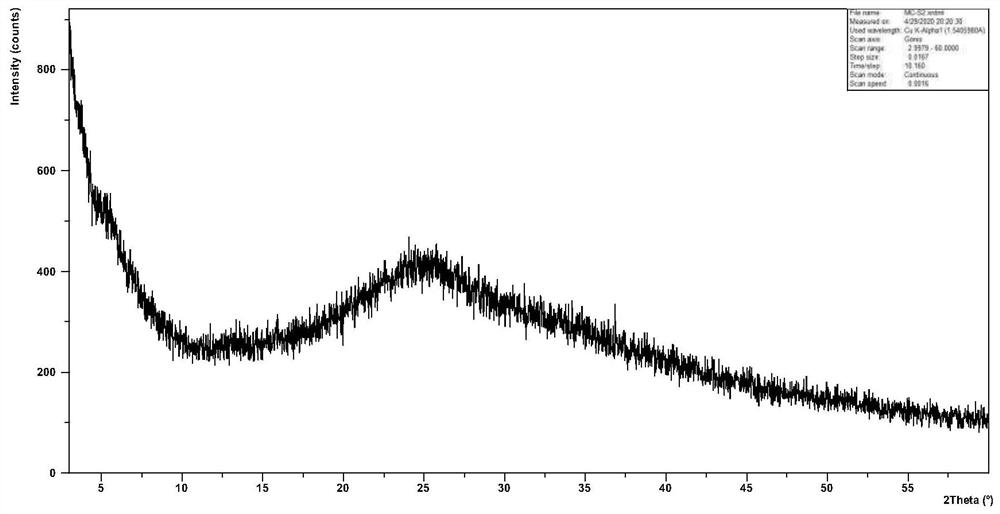

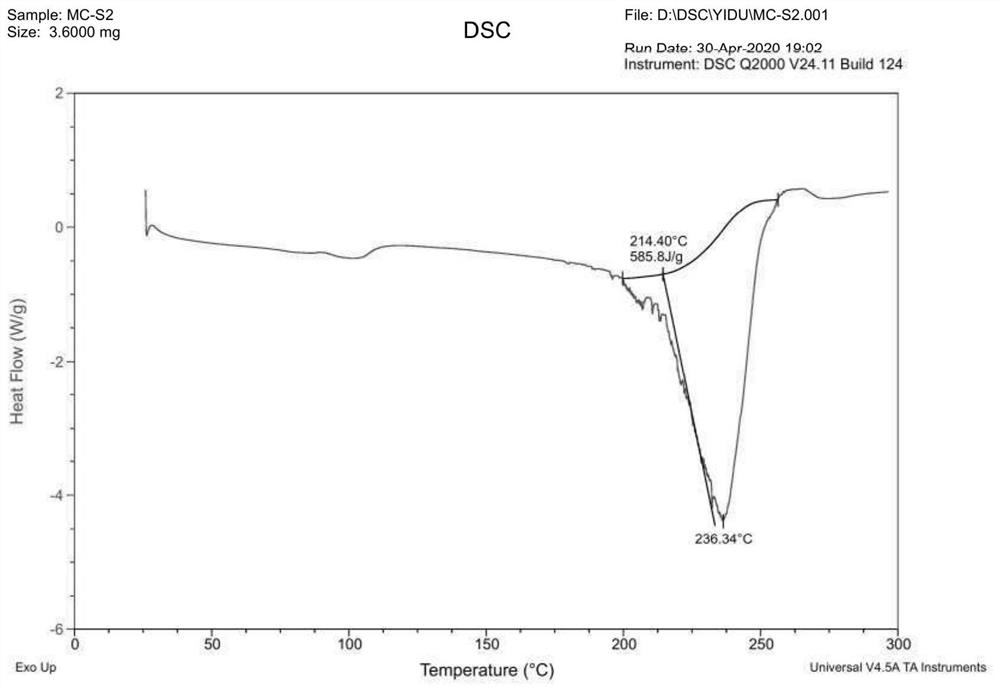

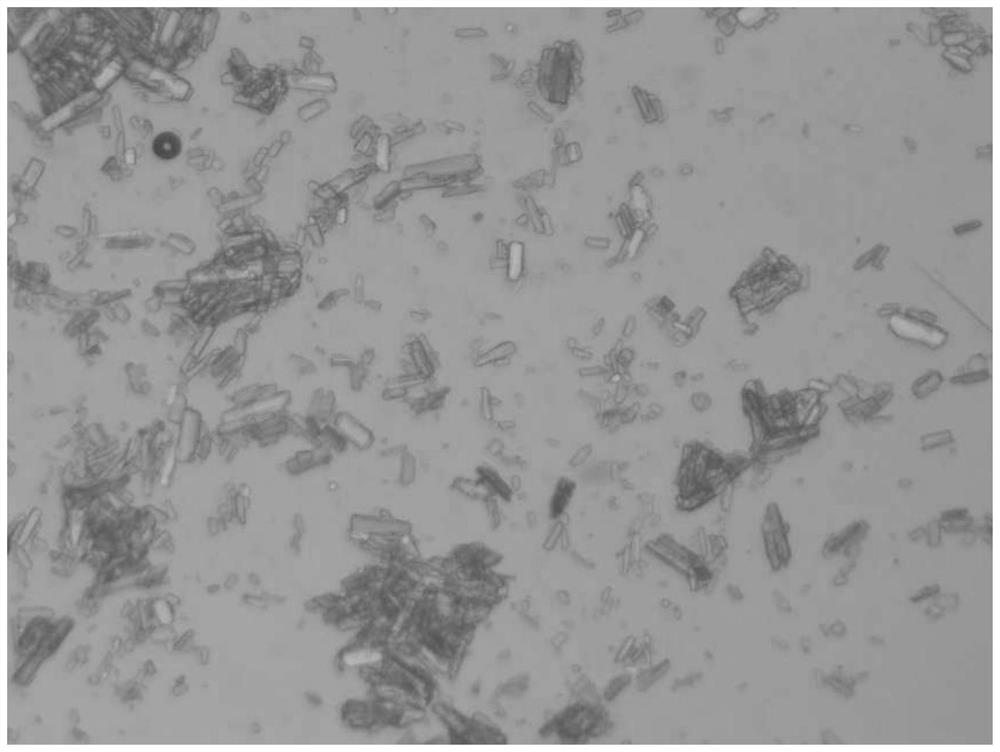

Image

Examples

Embodiment 1

[0033] The preparation method of the methacholine chloride amorphous crystal form described in the present embodiment, the steps are as follows:

[0034] First group:

[0035] (a) Weigh 100g of the crude methacholine chloride, put it in a container, add 100mL of acetonitrile to stir, slowly raise the temperature to 45-55°C, the crude methacholine chloride is not completely dissolved, take the acetonitrile and slowly add it dropwise to the system During the process, the dropwise addition of acetonitrile was stopped when the system just became clear, and the recorded dropwise amount of acetonitrile was 96 mL.

[0036] (b) Keep the solution system in (a) at 45-55°C, slowly add ethyl acetate dropwise to the system, stop adding ethyl acetate dropwise when the system starts to become cloudy, and record the amount of ethyl acetate dropwise as 352mL , stop heating.

[0037] (c) Continue to stir the cloudy solution in (b) to room temperature, then lower the temperature to 0-5°C and s...

Embodiment 2

[0050] The preparation method of the methacholine chloride amorphous crystal form described in the present embodiment, the steps are as follows:

[0051] First group:

[0052] (a) Weigh 100g of the crude methacholine chloride, place it in a container, add 200mL of n-butanol to stir, slowly raise the temperature to 45-55°C, the crude methacholine chloride is not completely dissolved, take n-butanol and slowly Add it dropwise to the system, stop adding n-butanol when the system just becomes clear, record the amount of n-butanol added dropwise as 88mL.

[0053] (b) Keep the solution system in (a) at 45-55°C, slowly add ethyl acetate dropwise to the system, stop adding ethyl acetate dropwise when the system starts to become cloudy, and record the amount of ethyl acetate dropwise as 278mL , stop heating.

[0054] (c) Continue to stir the cloudy solution in (b) to room temperature, then lower the temperature to 0-5°C and stir for 3 hours to precipitate crystals. The suspension wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com