A high-precision military sand table rapid prototyping device and method

A molding method and molding device technology are applied in the field of high-precision military sand table rapid prototyping devices, which can solve the problems of long time consumption and low dimensional accuracy of the sand table, and achieve the effect of broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

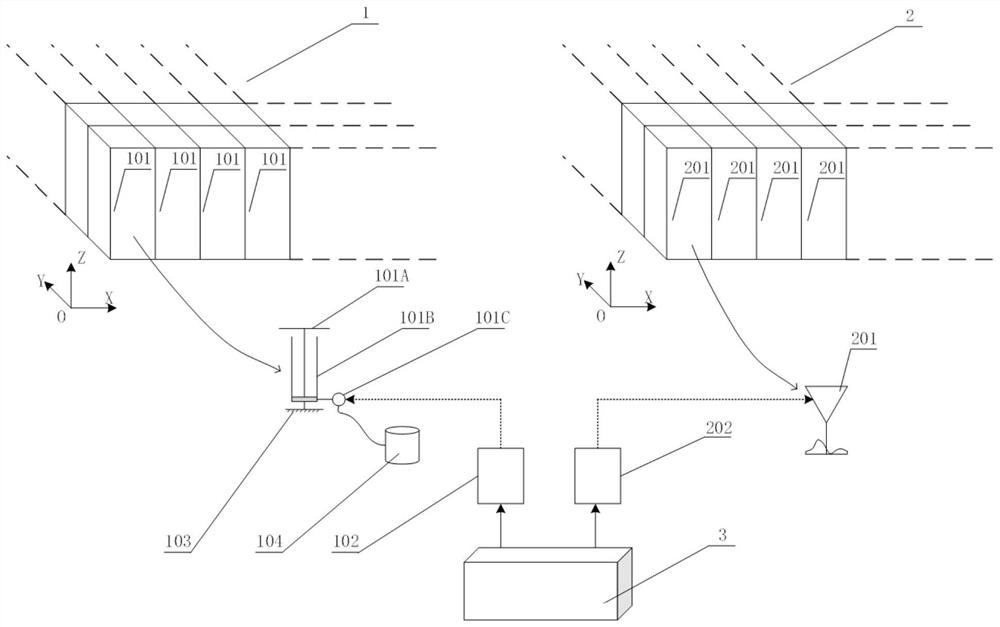

[0050] see Figure 1 to Figure 4 , the present embodiment provides a high-precision military sand table rapid prototyping device, which includes: a lower preforming system 1, an upper 3D printing system 2, and a data analysis system 3; wherein,

[0051]The lower preforming system 1 includes: a frame 103 and a preforming data processor 102; wherein, the frame 103 is provided with a plurality of preforming modules 101, and the top of each preforming module 101 is provided with a preforming table top 101A, and Each preforming module 101 is communicatively connected with the preforming data processor 102 respectively;

[0052] The preforming data processor 102 and the upper 3D printing system 2 are respectively connected in communication with the data analysis system 3; the data analysis system 3 is used to generate a plurality of module data corresponding to the number of preforming modules 101 according to the terrain data of the terrain to be simulated The preformed data proce...

no. 2 example

[0058] see Figure 1 to Figure 4 , the present embodiment provides a high-precision military sand table rapid prototyping method realized by the above-mentioned high-precision military sand table rapid prototyping device, the method comprising:

[0059] S1, obtaining the terrain data of the terrain to be simulated, and inputting the obtained data into the data analysis system 3;

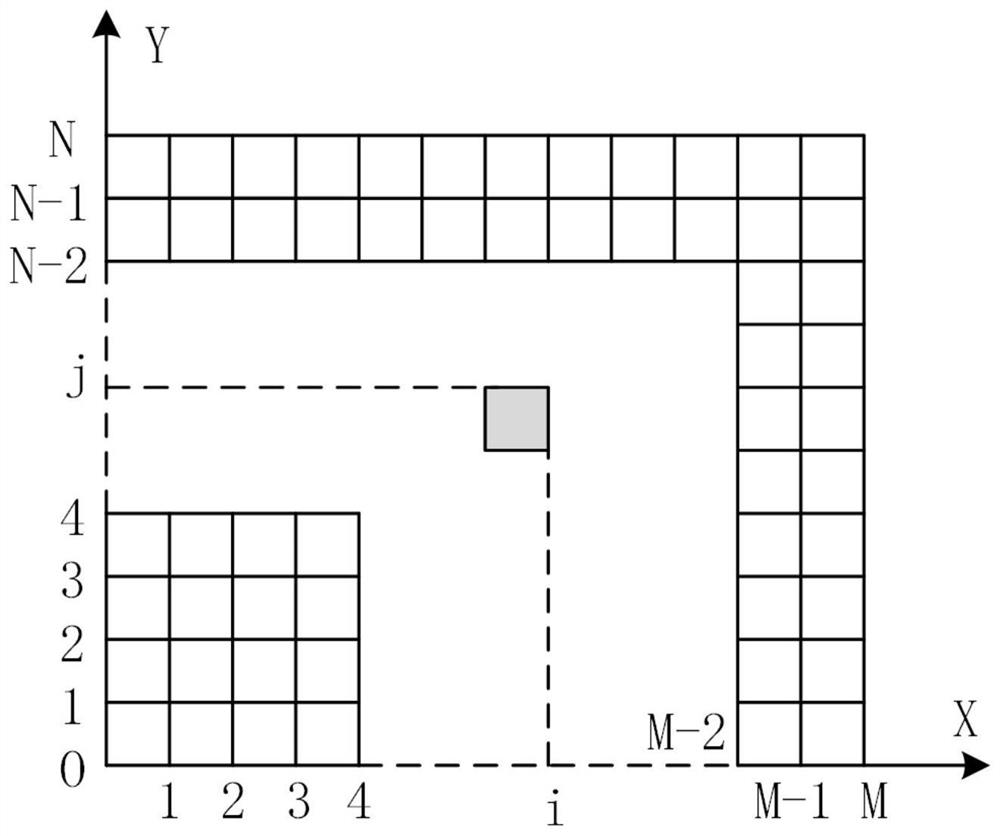

[0060] S2, preprocessing the acquired terrain data through the data analysis system 3, and dividing the preprocessed terrain data into a plurality of module data corresponding to the number of preforming modules 101;

[0061] S3, adjust the height of each preformed table 101A through the preformed data processor 102 according to the module data generated by the data analysis system 3 to form a prefabricated sand table;

[0062] S4, through the upper 3D printing system 2 according to the module data generated by the data analysis system 3, respectively perform 3D printing on the sand table topography...

no. 3 example

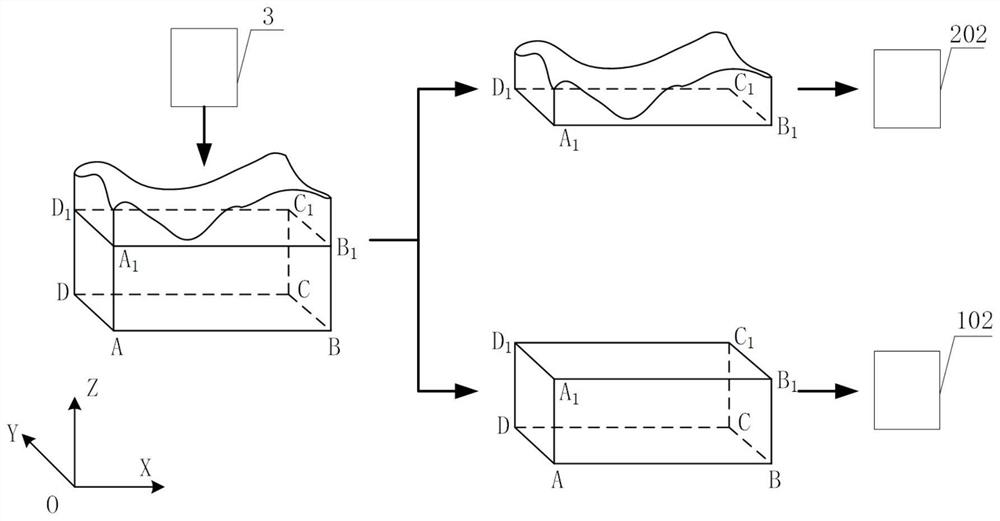

[0079] see Figure 5 to Figure 7 , this embodiment provides a high-precision military sand table rapid prototyping method realized by the above-mentioned high-precision military sand table rapid prototyping device, and the forming method is further explained with the help of a two-dimensional diagram:

[0080] Reconnaissance of the simulated terrain by unmanned aerial vehicle, got Figure 5 Terrain data shown.

[0081] Such as Figure 6 As shown, the three-dimensional terrain coordinate data obtained by the data analysis system 3 is scaled down, and the coordinates become the original 1 / k; wherein, k is a preset proportional constant; further, the terrain coordinate data of the sand table is modularized After processing, 6 modules from left to right are obtained, and the minimum Z coordinates of the 6 modules are marked as Z 1min ,Z 2min ,Z 3min ,Z 4min ,Z 5min ,Z 6min ;

[0082] Among them, the data processing and shaping method of the first module includes:

[0083...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com