High-precision military sand table rapid forming device and method

A molding device and molding method technology, which is applied in the field of high-precision military sand table rapid prototyping devices, can solve the problems of long time consumption and low sand table size accuracy, and achieve the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

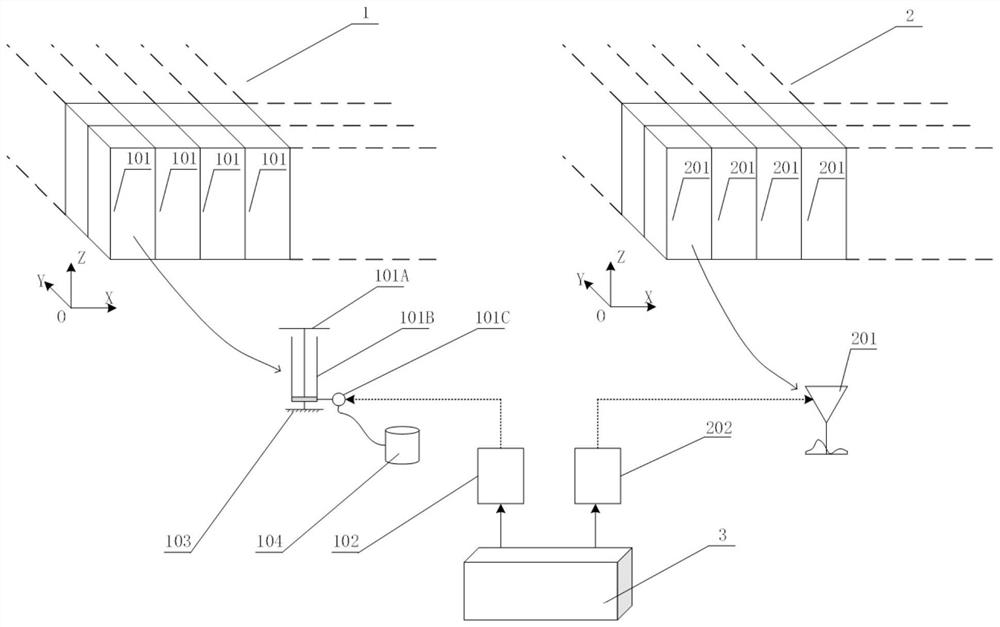

[0050] see Figure 1 to Figure 4 , the present embodiment provides a high-precision military sand table rapid prototyping device, which includes: a lower preforming system 1, an upper 3D printing system 2, and a data analysis system 3; wherein,

[0051]The lower preforming system 1 includes: a frame 103 and a preforming data processor 102; wherein, the frame 103 is provided with a plurality of preforming modules 101, and the top of each preforming module 101 is provided with a preforming table top 101A, and Each preforming module 101 is communicatively connected with the preforming data processor 102 respectively;

[0052] The preforming data processor 102 and the upper 3D printing system 2 are respectively connected in communication with the data analysis system 3; the data analysis system 3 is used to generate a plurality of module data corresponding to the number of preforming modules 101 according to the terrain data of the terrain to be simulated The preformed data proce...

no. 2 example

[0058] see Figure 1 to Figure 4 , the present embodiment provides a high-precision military sand table rapid prototyping method realized by the above-mentioned high-precision military sand table rapid prototyping device, the method comprising:

[0059] S1, obtaining the terrain data of the terrain to be simulated, and inputting the obtained data into the data analysis system 3;

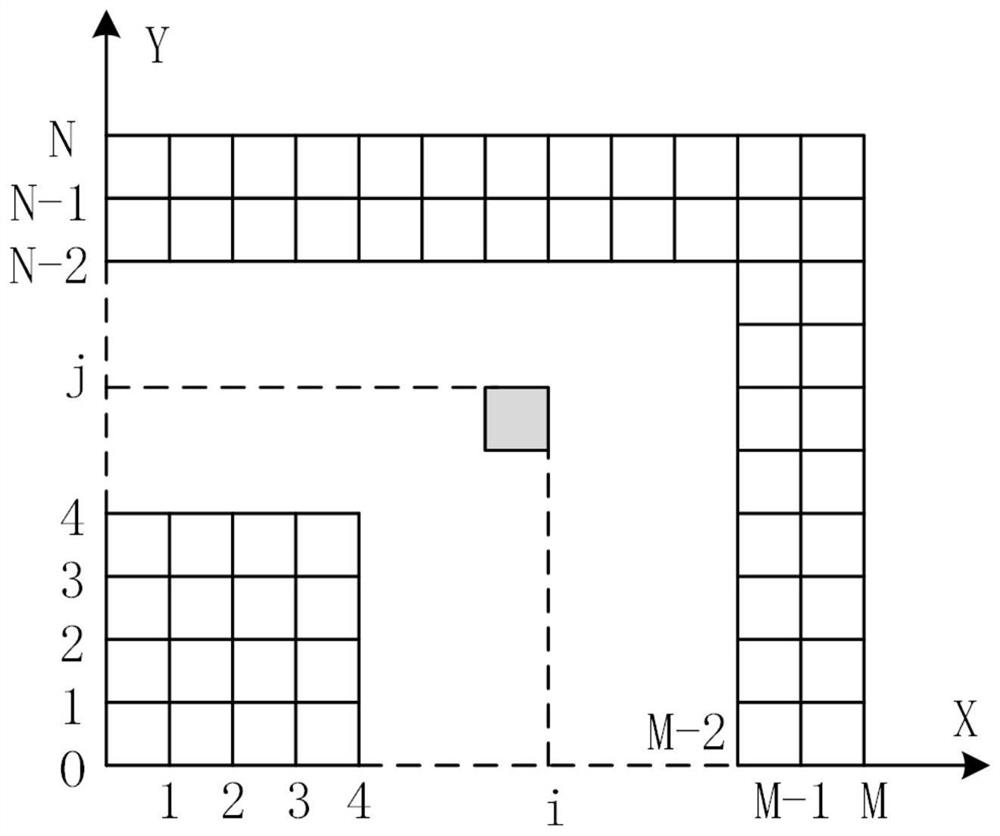

[0060] S2, preprocessing the acquired terrain data through the data analysis system 3, and dividing the preprocessed terrain data into a plurality of module data corresponding to the number of preforming modules 101;

[0061] S3, adjust the height of each preformed table 101A through the preformed data processor 102 according to the module data generated by the data analysis system 3 to form a prefabricated sand table;

[0062] S4, through the upper 3D printing system 2 according to the module data generated by the data analysis system 3, respectively perform 3D printing on the sand table topography...

no. 3 example

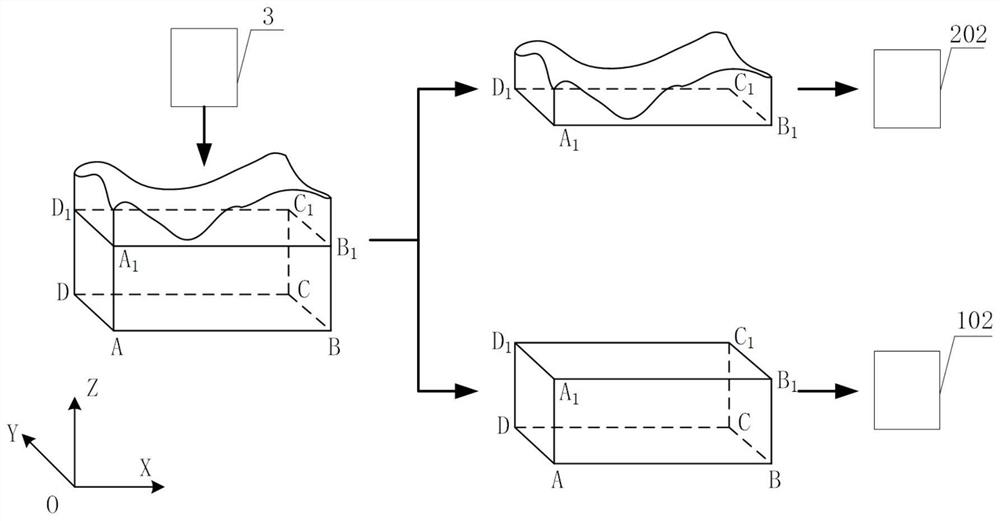

[0079] see Figure 5 to Figure 7 , this embodiment provides a high-precision military sand table rapid prototyping method realized by the above-mentioned high-precision military sand table rapid prototyping device, and the forming method is further explained with the help of a two-dimensional diagram:

[0080] Reconnaissance of the simulated terrain by unmanned aerial vehicle, got Figure 5 Terrain data shown.

[0081] Such as Figure 6 As shown, the three-dimensional terrain coordinate data obtained by the data analysis system 3 is scaled down, and the coordinates become the original 1 / k; wherein, k is a preset proportional constant; further, the terrain coordinate data of the sand table is modularized After processing, 6 modules from left to right are obtained, and the minimum Z coordinates of the 6 modules are marked as Z 1min ,Z 2min ,Z 3min ,Z 4min ,Z 5min ,Z 6min ;

[0082] Among them, the data processing and shaping method of the first module includes:

[0083...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com