One-time forming efficient PCD cutter for annular groove machining

A high-efficiency, ring-groove technology, which is applied to milling machine tools, manufacturing tools, metal processing equipment, etc., can solve problems such as not being able to meet the needs of mass production, and achieve good results, low processing costs, and stable processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

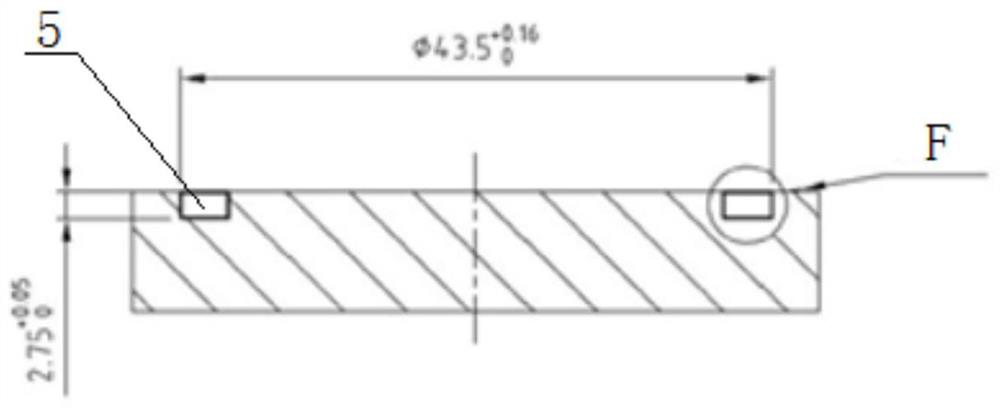

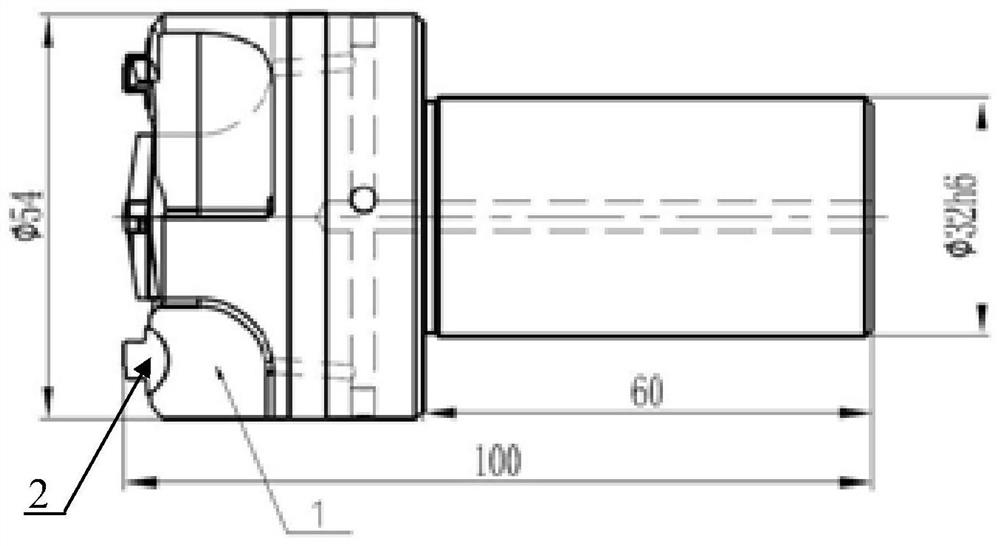

[0037] The following is to process on the retarder housing whose material is ADC12 figure 1 , 2 The ring groove of the shown specifications is taken as an example to further illustrate the present invention.

[0038] In order to improve the processing efficiency, we originally designed a composite ring groove milling cutter with cemented carbide inserts. Four identical shaped inserts are evenly and symmetrically arranged around the cutter body. One pass can directly process the figure 1 , 2 Dimensional features required. The processing efficiency of this solution is significantly improved compared with the above-mentioned traditional solution, but the roughness of the bottom of the ring groove cannot meet the requirements of Ra1.6, and after two or three hundred pieces of cutting tools are processed, obvious knife lines appear on the bottom of the groove (the processing effect is as follows Image 6 As shown), the vibration of the knife will also occur from time to time.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com