Superfine dry powder extinguishing agent and explosive combined cooperative fire extinguishing warhead for aerial bomb

A technology of ultra-fine dry powder and fire extinguishing agent, which is applied in the field of forest fire extinguishing. It can solve the problems of difficulty in suppressing the fire head, poor fire extinguishing effect, and extinguishing forest fires such as crown fires. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

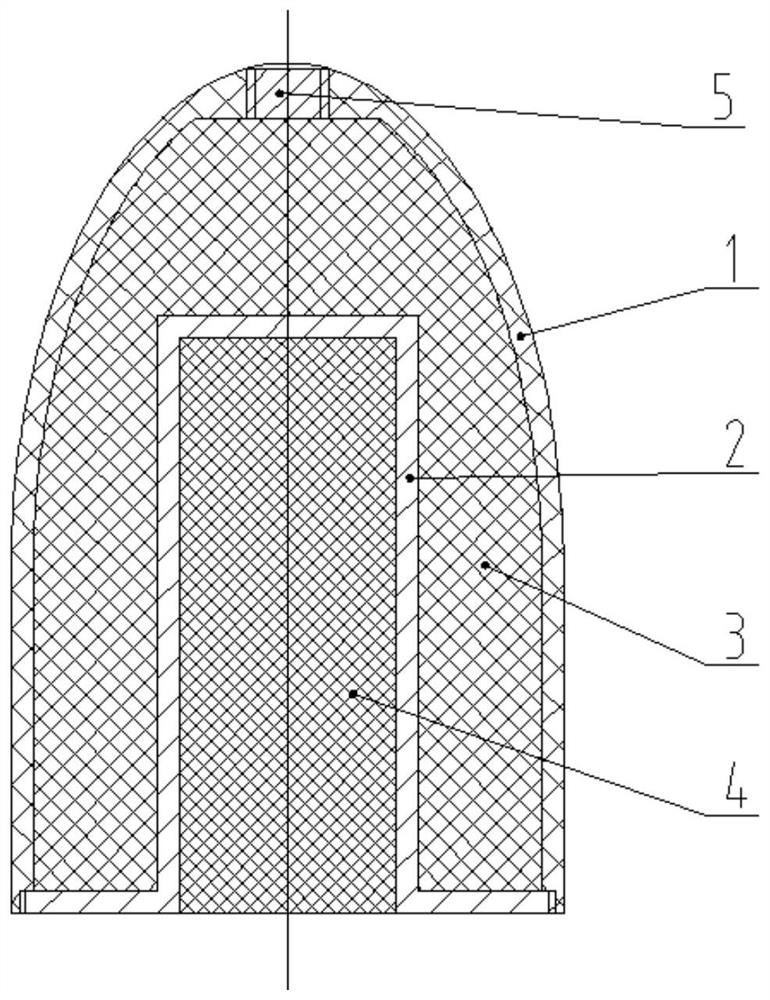

[0027] refer to figure 1 As shown, a combination of ultrafine dry powder fire extinguishing agent and explosives for aerial bombs disclosed in this embodiment cooperates with a fire extinguishing warhead, including a warhead shell 1, a preset sleeve 2, ultrafine dry powder fire extinguishing agent 3, and a main explosive 4 , head screw plug 5.

[0028] The warhead shell 1 adopts a thin-walled shell structure with a spherical upper part and a cylindrical bottom, and a threaded through hole for fixed connection with the head screw 5 is provided downward along the center of the top of the warhead shell 1; The bottom is provided with external threads for fixed connection with the preset sleeve 2; the cavity formed by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com