R-T-B series magnetic material and preparation method thereof

A R-T-B, magnetic material technology, applied in the direction of magnetic material, magnetic object, inductor/transformer/magnet manufacturing, etc., can solve the problems of limited improvement, high cost, no significant improvement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

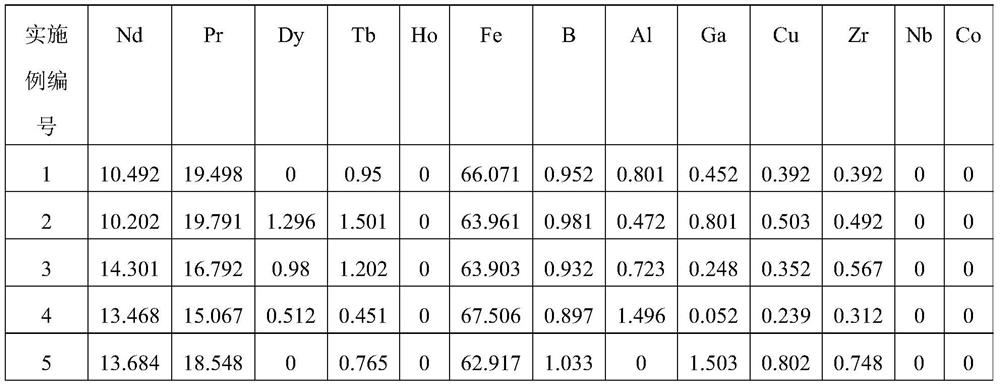

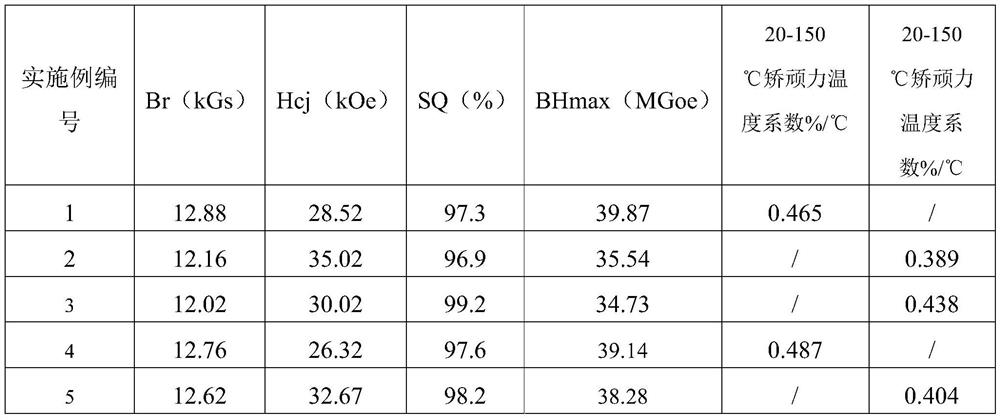

Embodiment 1

[0106] (1) Melting process: According to the formula shown in Table 1, take 50-500kg of the prepared raw materials, put them in a crucible made of alumina, and place them in a high-frequency vacuum induction melting furnace at 5×10 -2 Vacuum melting is performed at 1400-1500°C in a vacuum of Pa.

[0107] (2) Casting process: Ar gas is introduced into the smelting furnace after vacuum smelting to make the pressure reach 55,000 Pa, and then the casting is carried out. 2 ℃ / sec-10 4 The cooling rate of °C / sec obtains a quenched alloy.

[0108] (3) Hydrogen breaking and pulverizing process: Vacuum the hydrogen breaking furnace where the quench alloy is placed at 20-25℃ for 5×10 -2 Pa, then pass hydrogen with a purity of 99.9% into the hydrogen-breaking furnace, maintain the hydrogen pressure at 0.15MPa, fully absorb hydrogen, raise it to 500-550°C, fully dehydrogenate, then cool, and take out the hydrogen-breaking crushed powder.

[0109] (4) Fine pulverization process: Under a nitrogen a...

Embodiment 2

[0115] (1) Melting process: According to the formula shown in Table 1, take 50-500kg of the prepared raw materials, put them in a crucible made of alumina, and place them in a high-frequency vacuum induction melting furnace at 5×10 -2 Vacuum melting is performed at 1400-1500°C in a vacuum of Pa.

[0116] (2) Casting process: Ar gas is introduced into the smelting furnace after vacuum smelting to make the pressure reach 55,000 Pa, and then the casting is carried out. 2 ℃ / sec-10 4 The cooling rate of °C / sec obtains a quenched alloy.

[0117] (3) Hydrogen breaking and pulverizing process: Vacuum the hydrogen breaking furnace where the quench alloy is placed at 20-25℃ for 5×10 -2 Pa, then pass hydrogen with a purity of 99.9% into the hydrogen-breaking furnace, maintain the hydrogen pressure at 0.15MPa, fully absorb hydrogen, raise it to 500-550°C, fully dehydrogenate, then cool, and take out the hydrogen-breaking crushed powder.

[0118] (4) Fine pulverization process: Under a nitrogen a...

Embodiment 3

[0124] (1) Melting process: According to the formula shown in Table 1, take 50-500kg of the prepared raw materials, put them in a crucible made of alumina, and place them in a high-frequency vacuum induction melting furnace at 5×10 -2 Vacuum melting is performed at 1400-1500°C in a vacuum of Pa.

[0125] (2) Casting process: Ar gas is introduced into the smelting furnace after vacuum smelting to make the pressure reach 55,000 Pa, and then the casting is carried out. 2 ℃ / sec-10 4 The cooling rate of °C / sec obtains a quenched alloy.

[0126] (3) Hydrogen breaking and pulverizing process: Vacuum the hydrogen breaking furnace where the quench alloy is placed at 20-25℃ for 5×10 -2 Pa, then pass hydrogen with a purity of 99.9% into the hydrogen-breaking furnace, maintain the hydrogen pressure at 0.15MPa, fully absorb hydrogen, raise it to 500-550°C, fully dehydrogenate, then cool, and take out the hydrogen-breaking crushed powder.

[0127] (4) Fine pulverization process: Under a nitrogen a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com