Slurry filter press for kitchen garbage

A kitchen waste and hydraulic technology, which is applied in the direction of waste drying, dryers, cleaning methods and appliances, etc., can solve the problems of poor dehydration treatment of kitchen waste, insufficient drainage of water and grease in kitchen waste, etc. , to prevent clogging and reduce humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

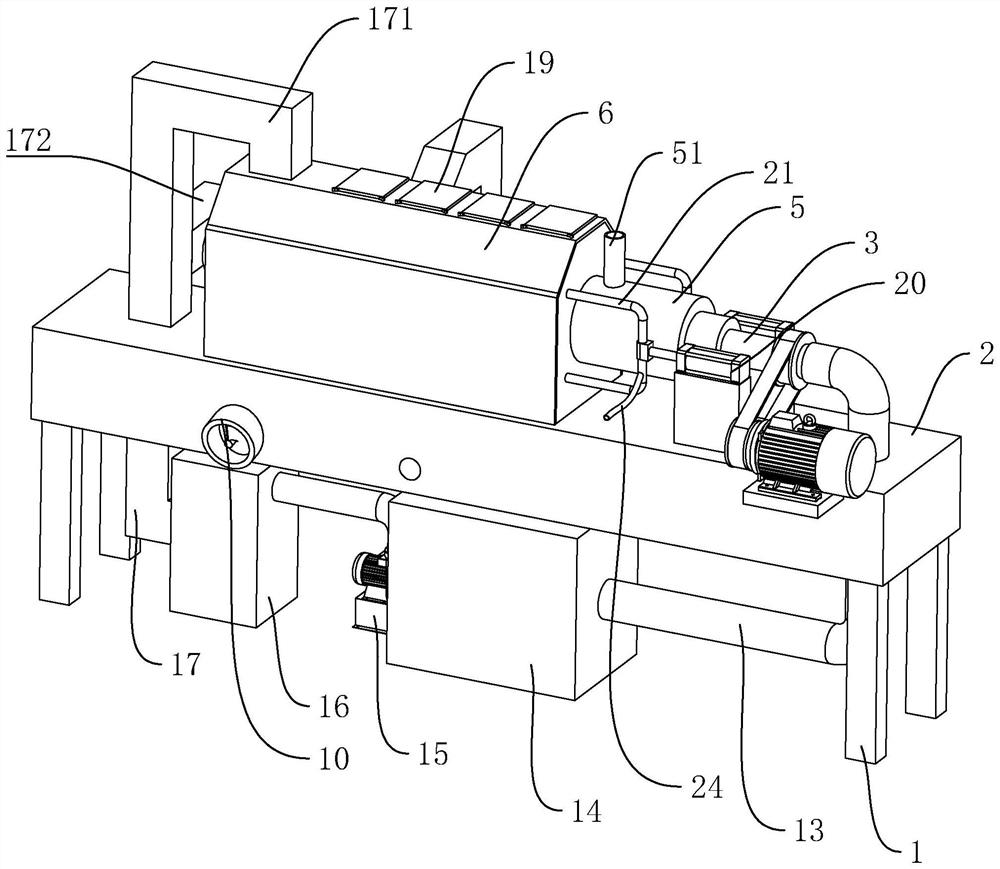

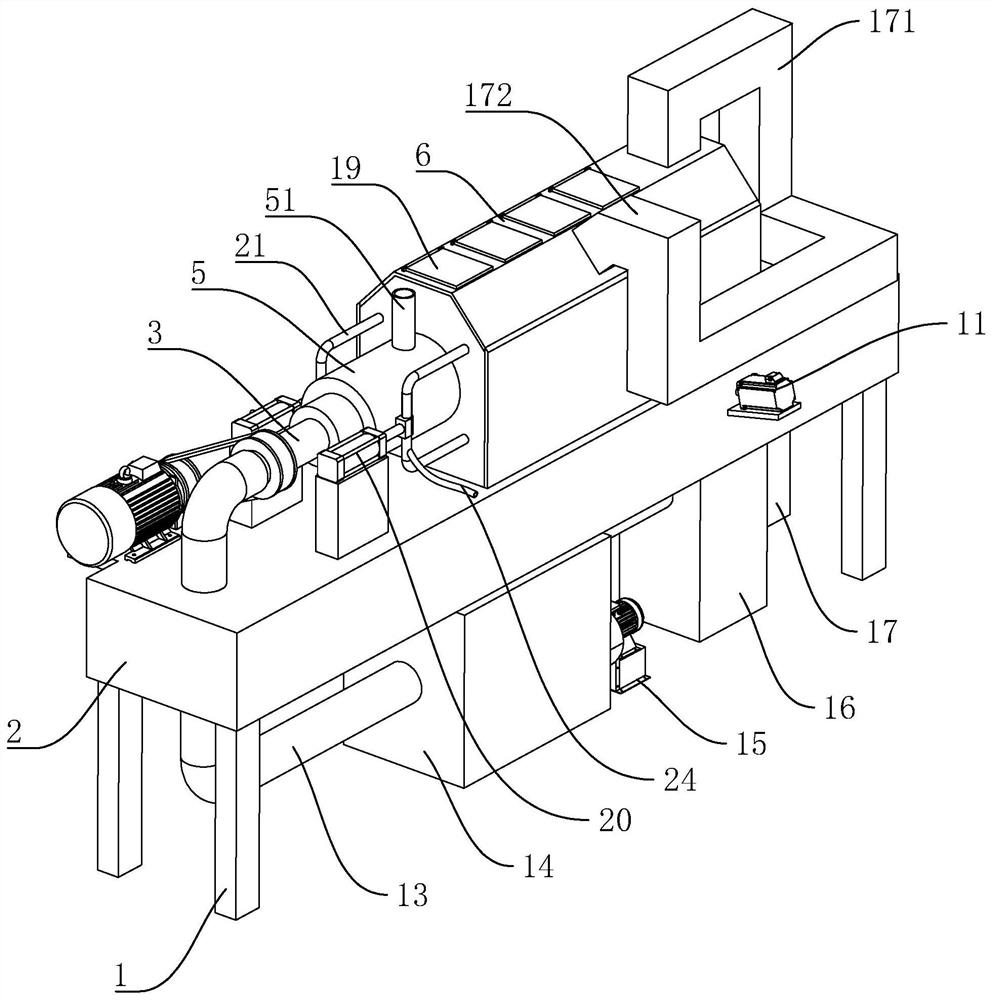

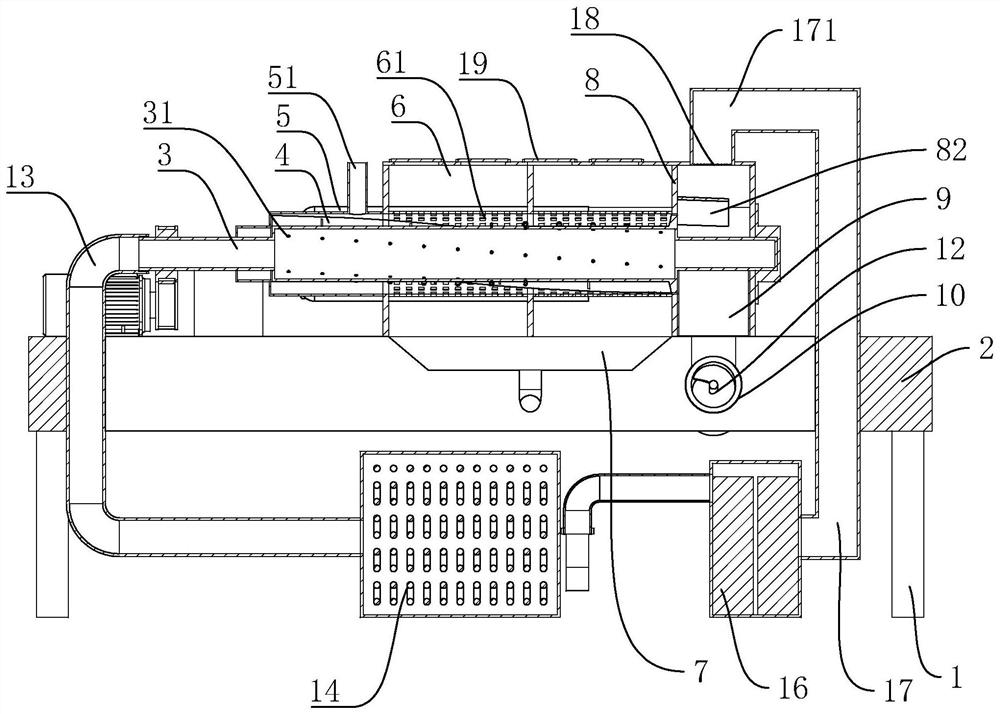

[0037] refer to figure 1 , is a kind of slurry hydraulic filter for kitchen waste disclosed by the present invention, comprising a frame 1 on which a workbench 2 is arranged. A separation chamber 6 is fixedly installed on the workbench 2, and several glass observation windows 19 are also hinged on the top of the separation chamber 6. refer to image 3 , the inside of the separation chamber 6 is equipped with a screening mesh cylinder 61; in the axial direction of the screening mesh cylinder 61, a feed chamber 5 communicating with the separation chamber 6 is also fixedly installed on the workbench 2 on one side of the separation chamber 6, A feeding port 51 for kitchen waste is provided at the top of the feeding chamber 5 . The side of the separation chamber 6 away from the feed chamber 5 is also connected with a discharge chamber 9, the separation chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com