Preparation method for improving purity of YIG (Yttrium Iron Gallium) nanofibers

A nanofiber, purity technology, applied in the field of nanomaterials, to achieve the effect of improving fiber purity, uniform ion diffusion, and reducing hysteresis loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

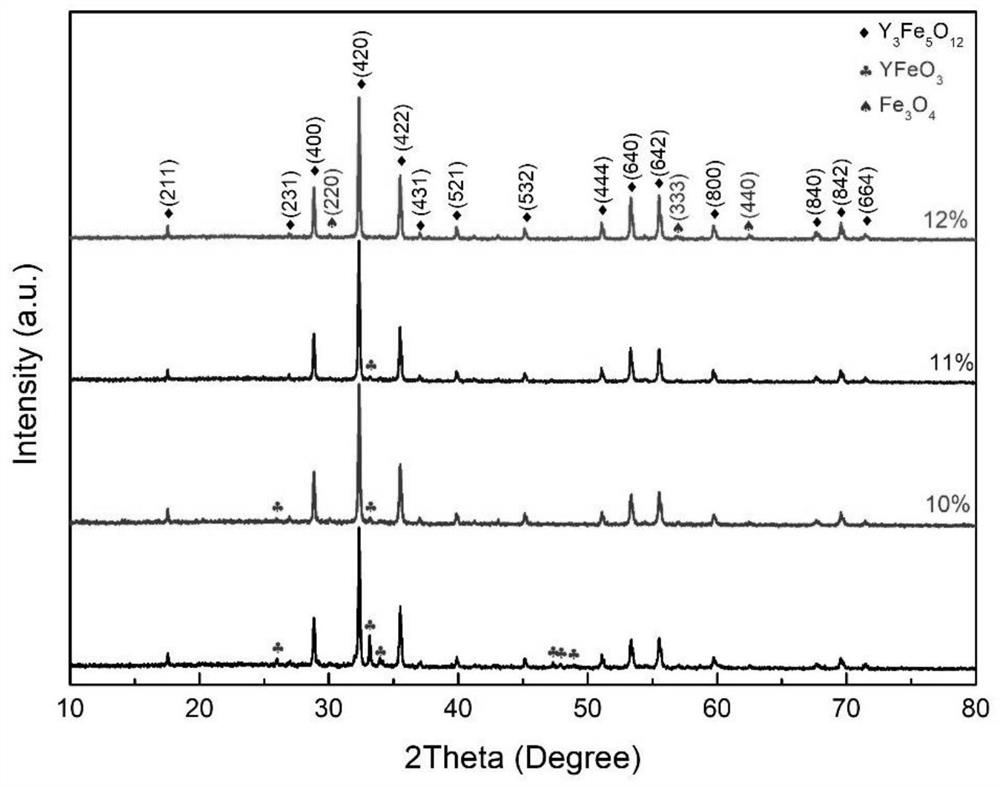

[0030] Embodiment one (change iron ion consumption)

[0031] 1. Configure YIG precursor solution

[0032] Take four glass bottles with a capacity of 30ml, numbered A, B, C, D, and weigh 1.8386g Y(NO 3 ) 3 ·6H 2 O four parts and 3.2979g, 3.3g, 3.6277g and 3.6936g Fe (NO 3 ) 3 9H 2 O was added to the glass bottle, and then 4ml of deionized water was added to it, and magnetically stirred for 30 minutes until it was completely dissolved, and four bottles of YIG aqueous solution were prepared into A, B, C, and D; another empty bottle was taken, and 1.6g of PVP was taken and 16ml of ethanol were added to it, and magnetically stirred for 1 hour until it was completely dissolved; respectively, 4ml of ethanol solution of PVP was taken and added dropwise to the aqueous solution of YIG while stirring. After the solution was mixed evenly, continue to stir for 30 minutes; The solute is dispersed evenly, and after standing for a period of time, a uniform and stable precursor solution ...

Embodiment 2

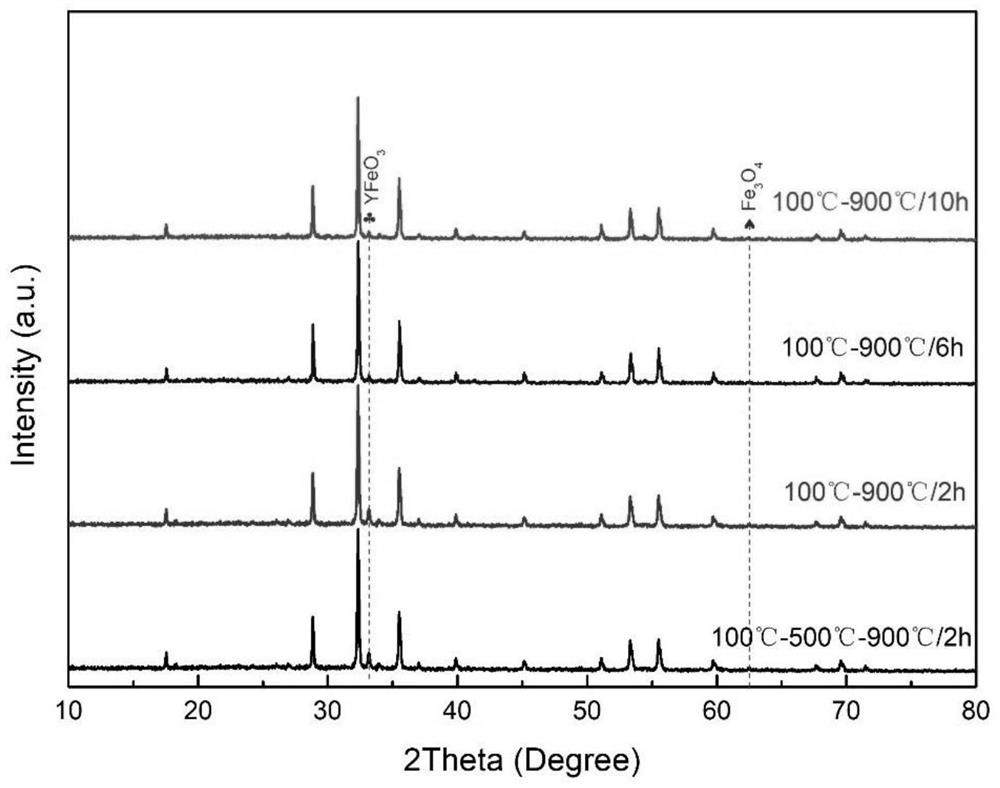

[0042] Embodiment two (change the annealing temperature holding time)

[0043] 1. Configure YIG precursor solution

[0044] Take a glass bottle with a capacity of 30ml, weigh 1.8386g Y(NO 3 ) 3 ·6H 2 O and 3.6277g Fe(NO 3 )3 9H 2 O was added to a glass bottle, and then 4ml of deionized water was added to it, and magnetically stirred for 30min until it was completely dissolved to obtain an aqueous solution of YIG; another empty bottle was taken, and 0.4g of PVP and 4ml of ethanol were added to it, and magnetically stirred for 1h. Until it is completely dissolved, the ethanol solution of PVP is obtained; the ethanol solution of PVP is added dropwise to the aqueous solution of YIG while stirring, and after the solution is mixed evenly, continue to stir for 30 minutes; After a period of time, a homogeneous and stable precursor solution with a certain viscosity was obtained.

[0045] 2. Electrospinning process

[0046] Transfer the prepared precursor solution to a 10ml syrin...

Embodiment 3

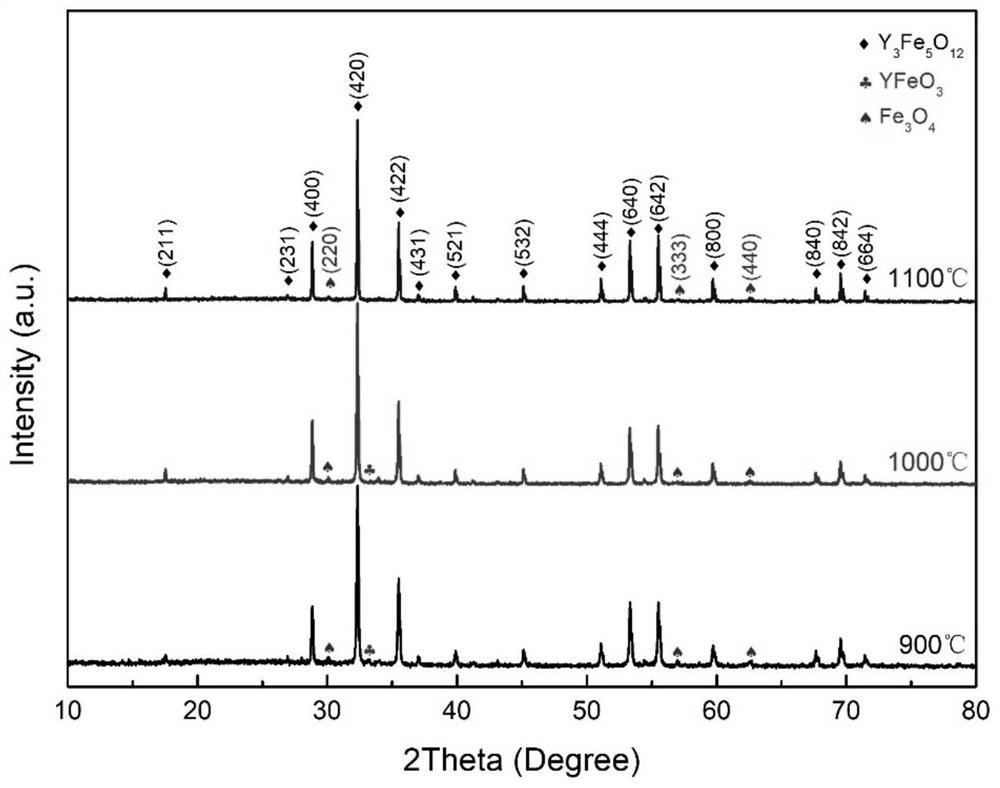

[0052] Embodiment three (change sintering temperature)

[0053] 1. Configure YIG precursor solution

[0054] Take a glass bottle with a capacity of 30ml, weigh 1.8386g Y(NO 3 ) 3 ·6H 2 O and 3.6607g Fe(NO 3 ) 3 9H 2 O was added to a glass bottle, and then 4ml of deionized water was added to it, and magnetically stirred for 30min until it was completely dissolved to obtain an aqueous solution of YIG; another empty bottle was taken, and 0.4g of PVP and 4ml of ethanol were added to it, and magnetically stirred for 1h. Until it is completely dissolved, the ethanol solution of PVP is obtained; the ethanol solution of PVP is added dropwise to the aqueous solution of YIG while stirring, and after the solution is mixed evenly, continue to stir for 30 minutes; After a period of time, a homogeneous and stable precursor solution with a certain viscosity was obtained.

[0055] 2. Electrospinning process

[0056] Transfer the prepared precursor solution to a 10ml syringe, and remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com