Martensitic steel copious cooling and high-pressure twisting mold and method

A technology of martensitic steel and high-pressure twisting, which is applied in the field of martensitic steel cryogenic and high-pressure twisting molds, can solve the problems of uniform and finer grains of high-strength steel and shorten the heat treatment time of high-strength steel, so as to improve mechanical properties, Increased elongation and restrained dynamic recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

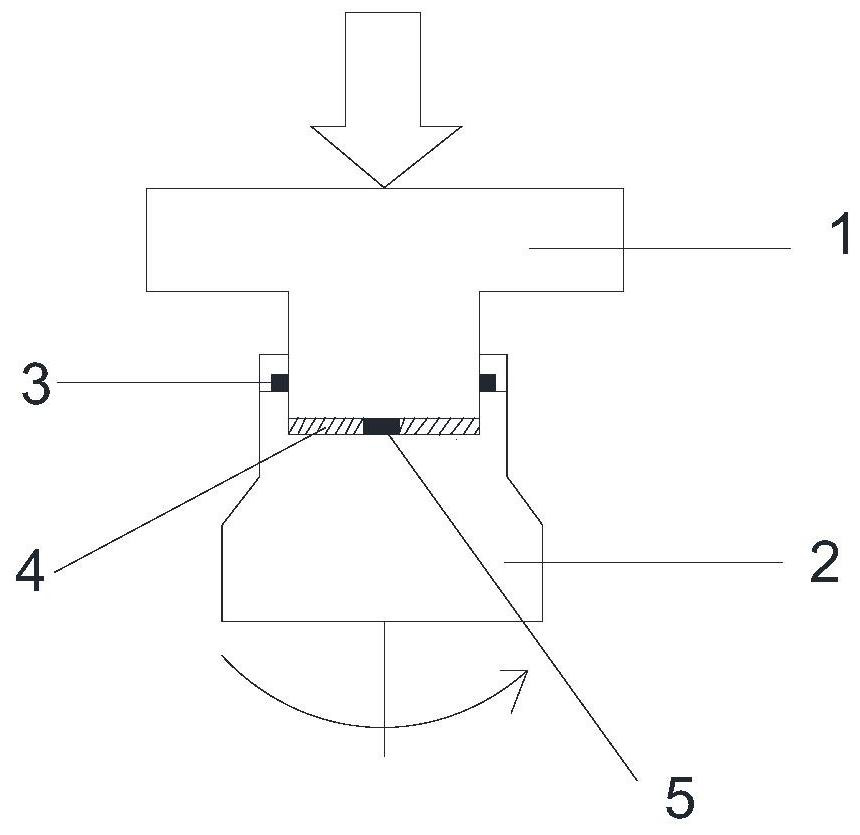

[0027] Such as figure 1 As shown, the present embodiment provides a martensitic steel cryogenic high-pressure rotary die, the die includes an upper die and a lower die, the upper surface of the lower die is provided with a cylindrical groove; the groove just covers The upper mold does not form constraints on the upper mold; a sealing structure 3 is provided between the upper mold and the lower mold. The sealing structure 3 includes a sealing ring, and the sealing ring is arranged at the opening of the groove. The sealing ring is fixed on the opening of the groove through a pressure ring, and the liquid nitrogen in the groove is isolated from the outside through the sealing structure 3, so as to prevent the gasification loss of the liquid nitrogen and achieve the best cryogenic treatment effect.

[0028] In this embodiment, the mold material is cemented carbide.

Embodiment 2

[0030] Put the 1.8mm thick USIBOR1500 martensitic high-strength steel sheet sample 5 into the groove of the lower mold 2, the upper mold 1 presses down on the sample 5, fills the groove with liquid nitrogen 4, and then puts the upper mold 1 The mold and the lower mold are sealed, and the sample is subjected to cryogenic treatment for 20 minutes. After the cryogenic treatment of the sample, high-pressure twisting is performed under a pressure of 4GPa, that is, the lower mold is turned, and the rotation angle is 360°. Then anneal and recrystallize at 750°C in a spark plasma sintering machine, the holding time is 20 minutes, and air cool after the holding.

Embodiment 3

[0032] Put the 1.6mm thick USIBOR1500 martensitic high-strength steel sheet sample 5 into the groove of the lower mold 2, the upper mold 1 presses down on the sample, fills the groove with liquid nitrogen 4, and then puts the upper mold It is sealed with the lower mold, and the sample is subjected to cryogenic treatment for 20 minutes. After the cryogenic treatment of the sample, high-pressure twisting is carried out under the pressure of 5GPa, that is, the lower mold is turned, and the rotation angle is 360°. Then anneal and recrystallize at 750°C in a spark plasma sintering machine, the holding time is 20 minutes, and air cool after the holding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com