Ultralight release force free radical photocuring release film and preparation method thereof

An ultra-light release, light-curing technology, applied in the direction of film/sheet release liner, adhesive, etc., can solve the problem of not meeting the requirements, achieve good adhesion, stable aging release force, stable chemical and physical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

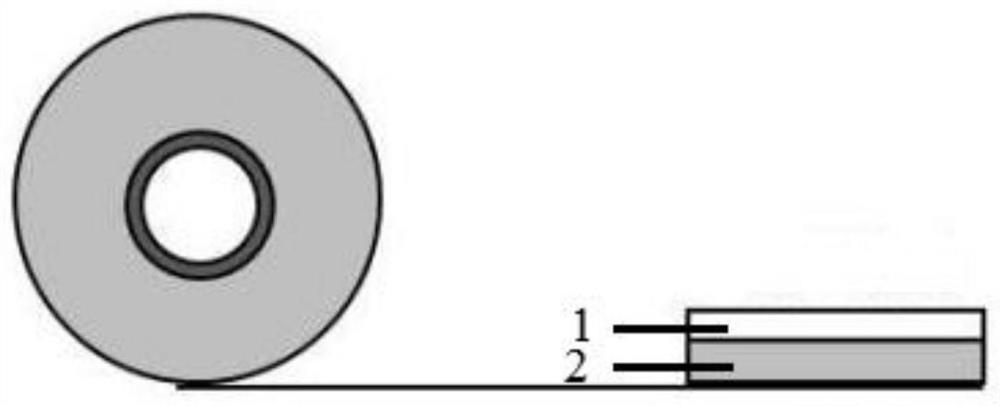

Image

Examples

Embodiment 1

[0054] 7kg acrylate-based polysiloxane TEGO RC 902, 2kg hyperbranched polysiloxane X-62-7989, 0.1kg leveling agent TEGO Glide 410, 0.3kg adhesion additive SR9051, 0.2kg antistatic agent phosphate group B Base acrylate, 0.1kg fumed silica powder CAB-O-SIL TG-829F and 0.3kg photoinitiator PhotoiniciatorA18 are mixed, stirred evenly, poured into a storage tank equipped with an agitator for coating, and put it on the coating machine After putting on the PP film, after corona treatment with a corona value of 40 dynes, the coating process is carried out. During the coating process, nitrogen gas is passed through, and the ultraviolet lamp is turned on to cure at 45 ° C. After the curing is completed, the winding is obtained. product1.

Embodiment 2

[0056] 6kg acrylate-based polysiloxane TEGO RC 902, 3kg hyperbranched polysiloxane X-62-7989, 0.1kg leveling agent TEGO Glide 410, 0.3kg adhesion additive SR9051, 0.2kg antistatic agent phosphate group B Base acrylate, 0.1kg fumed silica powder CAB-O-SIL TG-829F and 0.3kg photoinitiator PhotoiniciatorA18 are mixed, stirred evenly, poured into a storage tank equipped with an agitator for coating, and put it on the coating machine Put on the PE film, go through the corona treatment with a corona value of 38 dynes, and then carry out the coating process. During the coating process, nitrogen gas is introduced, and the ultraviolet lamp is turned on to cure at 50 ° C. After the curing is completed, the winding is obtained. product2.

Embodiment 3

[0058] 5kg acrylate-based polysiloxane TEGO RC 902, 4kg hyperbranched polysiloxane X-62-7989, 0.1kg leveling agent TEGO Glide 410, 0.3kg adhesion additive SR9051, 0.2kg antistatic agent phosphate group B Base acrylate, 0.1kg fumed silica powder CAB-O-SIL TG-829F and 0.3kg photoinitiator PhotoiniciatorA18 are mixed, stirred evenly, poured into a storage tank equipped with an agitator for coating, and put it on the coating machine Put on the PET film, go through the corona treatment with a corona value of 38 dynes, and then carry out the coating process. During the coating process, nitrogen gas is introduced, and the ultraviolet lamp is turned on to cure at 50°C. After the curing is completed, the winding is obtained. Product 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com