Wet-process sprayed ultra-high performance concrete rheological property regulator and using method thereof

An ultra-high performance, wet spraying technology, which is applied in the field of wet spraying ultra-high performance concrete rheological property modifiers, can solve the problems of reducing rebound rate, insufficient durability and environmental adaptability, and yield stress, etc., to improve Effects of early strength, improved sprayability, and improved yield stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

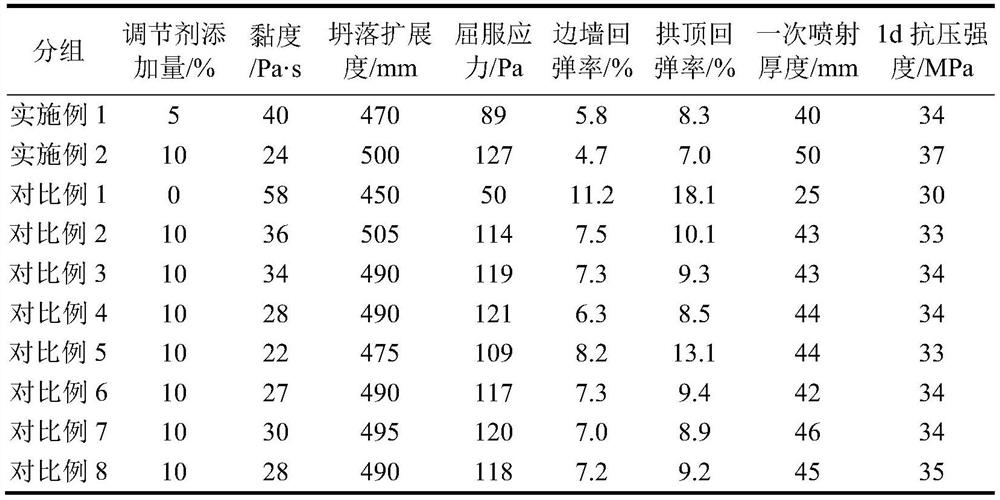

Examples

Embodiment 1

[0048] The rheology regulator for wet sprayed ultra-high performance concrete includes 45% viscosity reducing component, 35% anti-sagging component, and 20% early strength component. The specific composition of each component is as follows:

[0049] The composition in the viscosity reducing component is 70% by mass, the particle size is 1 μm, and the specific surface area is 2600m 2 / kg of fly ash floating beads and 20% of the particle size of 60nm nano-calcium carbonate and 10% of the particle size of 200μm tourmaline powder;

[0050] Component A in the anti-sag component is 50% by mass of bentonite with a particle size of 75 μm and 50% by mass of montmorillonite with a particle size of 0.2 μm, wherein the bentonite is acidified before use: according to The mass ratio of 0.15:1 is to take the bentonite after removing impurities and sand and drying and the hydrochloric acid solution with a concentration of 15%, and acidify the bentonite with the hydrochloric acid solution for ...

Embodiment 2

[0053] The rheological performance regulator of wet sprayed ultra-high performance concrete includes 50% viscosity reducing component, 30% anti-sagging component, and 20% early strength component. The specific composition of each component is as follows:

[0054] The composition in the viscosity reducing component is 50% by mass, the particle size is 5μm, and the specific surface area is 3000m 2 / kg of fly ash floating beads and 20% of the particle size of 80nm nano-calcium carbonate and 30% of the particle size of 450 μm tourmaline powder;

[0055] Component A in the anti-sagging component is 40% by mass of bentonite with a particle size of 150 μm and 60% by mass of montmorillonite with a particle size of 0.2 μm, wherein the bentonite is acidified before use: according to The mass ratio of 1:10 is to take the bentonite after removing impurities and sand and drying it and the hydrochloric acid solution with a concentration of 10%, and acidify the bentonite with the hydrochlori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com