A method for improving sludge dewatering effect by using sodium perfluorooctanoate wastewater

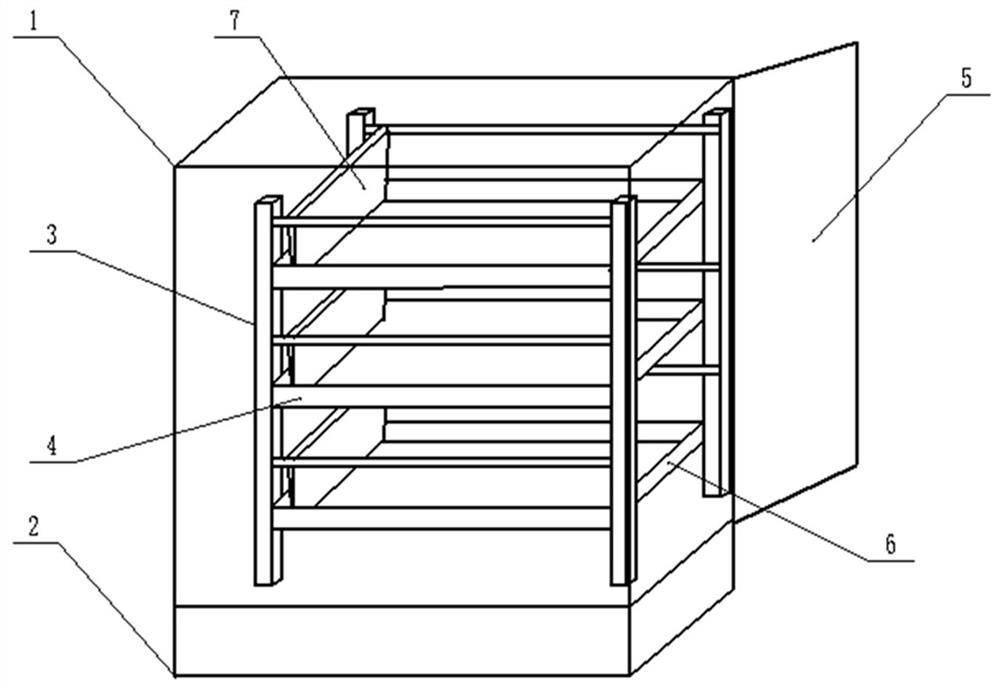

A technology for sodium perfluorooctanoate and sludge dehydration, applied in water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, sludge treatment, etc., to prevent excessive sludge viscosity, facilitate eradication, and improve freeze-drying The effect of disk structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

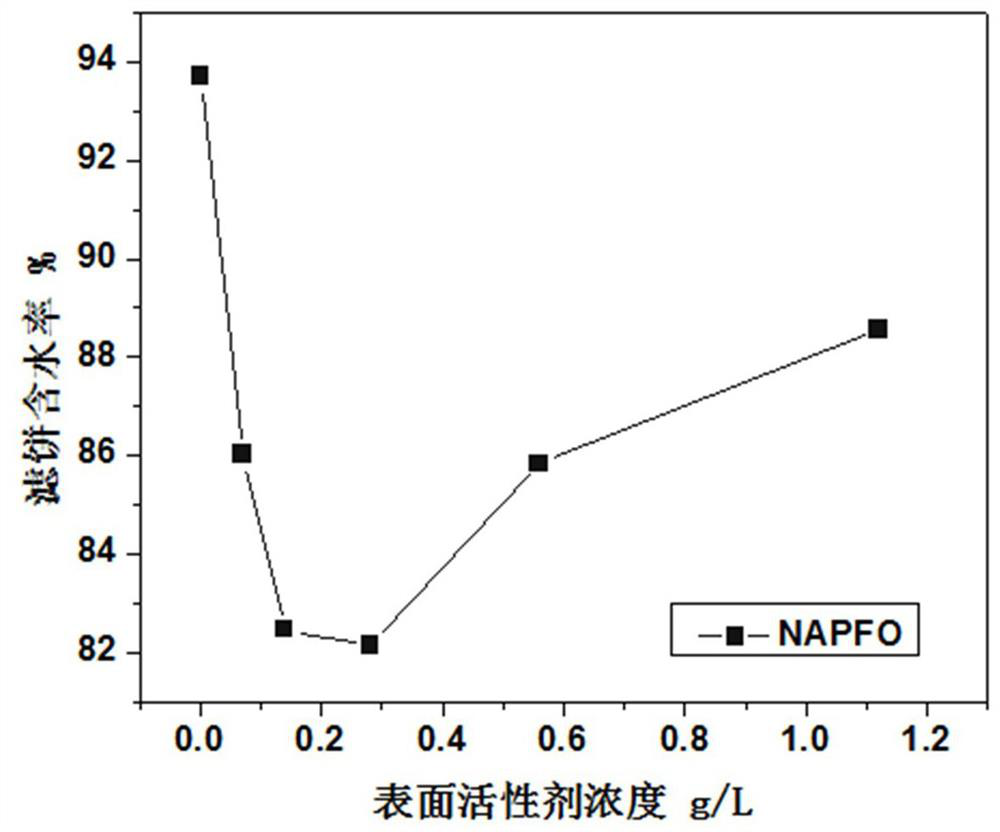

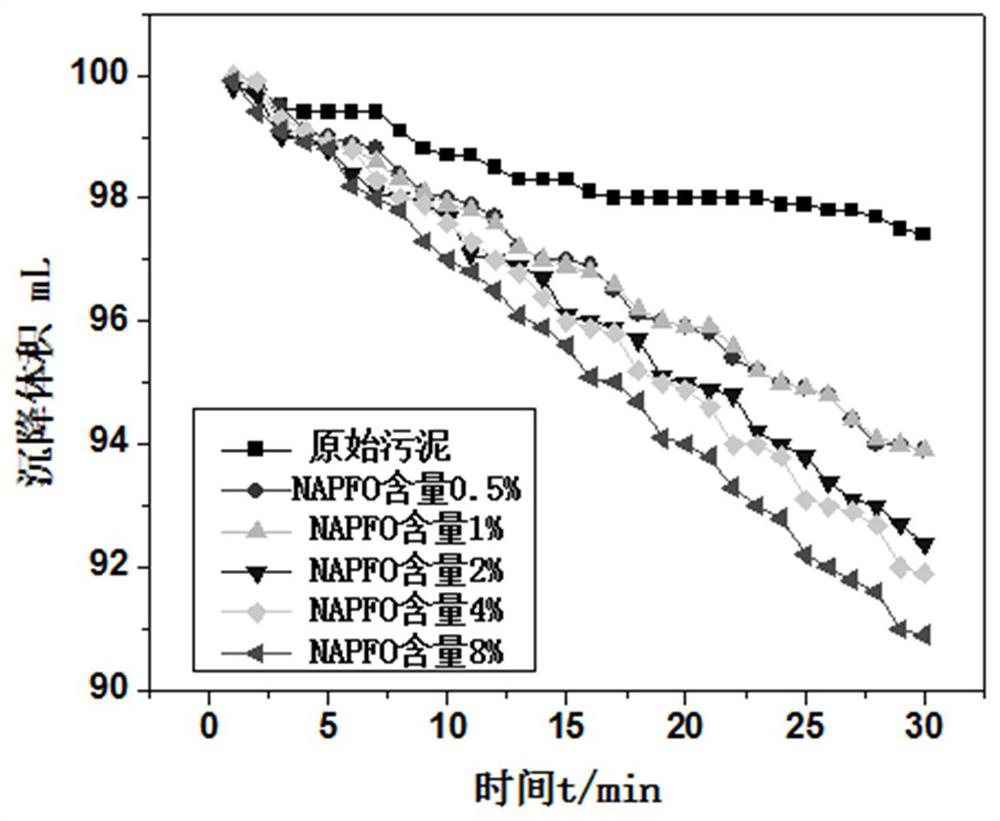

[0028] A method of utilizing sodium perfluorooctanoate wastewater to improve sludge dewatering effect, characterized in that the steps are as follows:

[0029] (1) Sludge drying, fresh sludge drying at 95℃ for 48h.

[0030] (2) Treatment of sodium perfluorooctanoate wastewater, take the wastewater containing sodium perfluorooctanoate and filter to remove impurities to clarify the wastewater, then add NaOH to adjust the pH of the wastewater at 6, and then adopt the osmosis method to obtain a mother liquor containing sodium perfluorooctanoate with a concentration of 5g / L.

[0031] (3) mixing, stirring and dehydration, the sludge dried in step (1) and the mother liquor containing sodium perfluorooctanoate obtained in step (2) are first stirred at high speed and then fully mixed at low speed in the ratio of adding 56 mL of mother liquor per liter of sludge, and then The supernatant was removed by standing and settling; the high-speed stirring time was 30s, and the speed was 160r / m...

Embodiment 2

[0034] A method of utilizing sodium perfluorooctanoate wastewater to improve sludge dewatering effect, characterized in that the steps are as follows:

[0035] (1) Drying of sludge, drying of fresh sludge at 100°C for 60h.

[0036] (2) Treatment of sodium perfluorooctanoate wastewater, take the wastewater containing sodium perfluorooctanoate and filter to remove impurities to clarify the wastewater, then add NaOH to adjust the pH of the wastewater at 8, and then adopt the osmosis method to obtain a mother liquor containing sodium perfluorooctanoate with a concentration of 5g / L.

[0037] (3) mixing, stirring and dehydration, the sludge dried in step (1) and the mother liquor containing sodium perfluorooctanoate obtained in step (2) are mixed with high-speed stirring and then low-speed stirring at the ratio of adding 112 mL of mother liquor per liter of sludge, and then The supernatant was removed by standing and settling; the high-speed stirring time was 40s, and the speed was ...

Embodiment 3

[0040] A method of utilizing sodium perfluorooctanoate wastewater to improve sludge dewatering effect, characterized in that the steps are as follows:

[0041] (1) Drying of sludge, drying of fresh sludge at 105°C for 72h.

[0042] (2) The treatment of sodium perfluorooctanoate wastewater, take the wastewater containing sodium perfluorooctanoate and filter to remove impurities to clarify the wastewater, then add NaOH to adjust the pH of the wastewater to be 11, and then adopt the osmosis method to obtain a mother liquor containing sodium perfluorooctanoate with a concentration of 5g / L.

[0043] (3) Mixing and stirring dehydration, the sludge dried in step (1) and the mother liquor containing sodium perfluorooctanoate obtained in step (2) are first stirred at high speed and then fully mixed at low speed in the ratio of adding 224 mL of mother liquor per liter of sludge, and then The supernatant was removed by standing and settling; the high-speed stirring time was 50s, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com