Multifunctional Pneumatic Hole Sealing Device and Its Matching Hole Sealing Process

A sealing device, multi-functional technology, used in sealing/isolation, drilling composition, wellbore/well components, etc., can solve the problem of high operating quality requirements, affecting the drainage effect, and destroying the integrity of the rigid foam And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

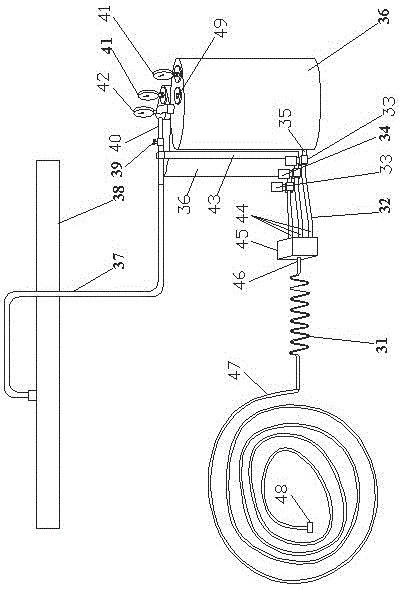

[0029] Depend on figure 1 A multi-functional pneumatic sealing device shown includes a pneumatic cylinder 36 with a material inlet and a material outlet 35 , an air pressure pipe 38 , a mixing joint 45 and a mixing pipe 31 . The feed port and discharge port 35 of the pneumatic cylinder 36 are respectively located at the top and bottom of the pneumatic cylinder 36, the feed port of the pneumatic cylinder 36 is provided with a sealing cover 49, and the discharge port 35 of the pneumatic cylinder 36 is provided with a flow regulating valve 33. The top of the pneumatic cylinder 36 is also provided with an air inlet, the pneumatic cylinder 36 is provided with a pointer type float level gauge 41, the pneumatic cylinder 36 is airtight, and there are two pneumatic cylinders 36 in total.

[0030] The air pressure pipe 38 communicates with a connecting pipe 37 , and the end of the connecting pipe 37 is connected to the first branch pipe 43 and the second branch pipe 40 . The two air in...

Embodiment 2

[0036] Depend on figure 1 with figure 2As shown in the pressure measuring drilling and sealing process, the gas drainage drilling and sealing device as described in Example 1 is first installed, and a certain amount of The black and white materials of the pre-proportioned polyurethane solution.

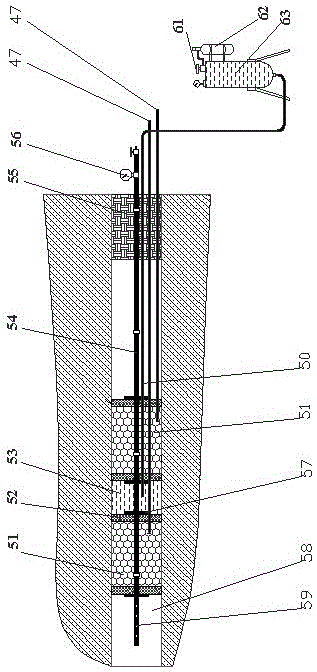

[0037] Before the sealing tube 54 is inserted into the borehole 58, four spacers are arranged at intervals on the outer ring of the sealing tube 54, and the spacers are rubber pads 52, and the four rubber pads 52 are respectively fixed on the outer ring of the sealing tube 54. On the four fixed discs 57 fixed at intervals, (of course, if there is no rubber pad 52, the separator can be replaced by a towel, or wrapped around the sealing tube 54), three regions are formed in turn between the four rubber pads 52 : Side area and middle area. There are two sealing conduits 47 connected to the outlet of the mixing tube 31 at the same time. The two sealing conduits 47 are inserted through...

Embodiment 3

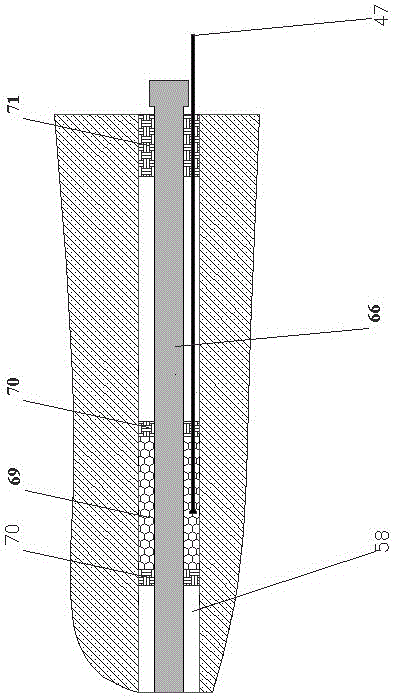

[0043] Depend on figure 1 with image 3 In the shown drainage drilling and sealing process, the gas drainage drilling and sealing device as described in Embodiment 1 is first provided, and a certain amount of gas is respectively loaded into the two pneumatic cylinders 36 of the gas drainage drilling and sealing device The black material and the white material of the polyurethane feed liquid prepared in proportion in advance, and the pressure air pipe 38 are connected to the downhole pressure air pipeline.

[0044] Set two blocking pieces 70 on the drainage pipe 66 at intervals. The blocking pieces 70 are towels wrapped around the outer ring of the drainage pipe 66 respectively. between the blocking members 70, and bind the sealing conduit 47 on the extraction pipe 66.

[0045] Then the extraction pipe 66 is inserted into the predetermined depth in the coal seam borehole 58, and the pressure air pipe 38 is connected with the downhole pressure air pipeline, and is passed throu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com