Electronic hydraulic pressurization system and control method

A supercharging system and electronic control unit technology, applied in the direction of braking safety system, etc., to achieve good compensation ability, ensure personal and property safety, and maintain the effect of braking ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

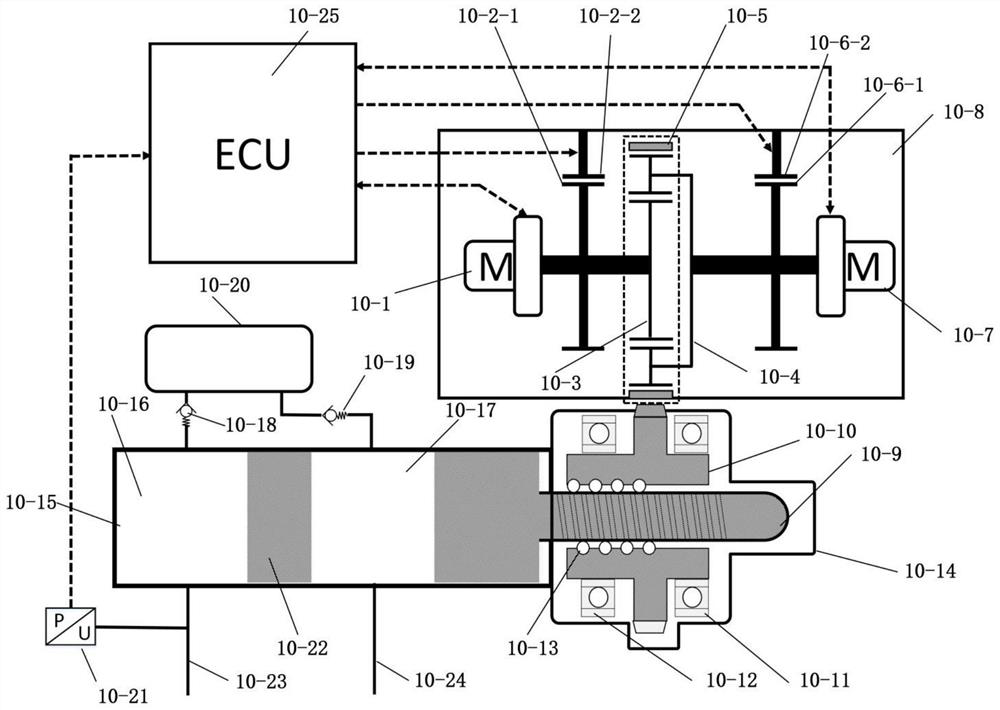

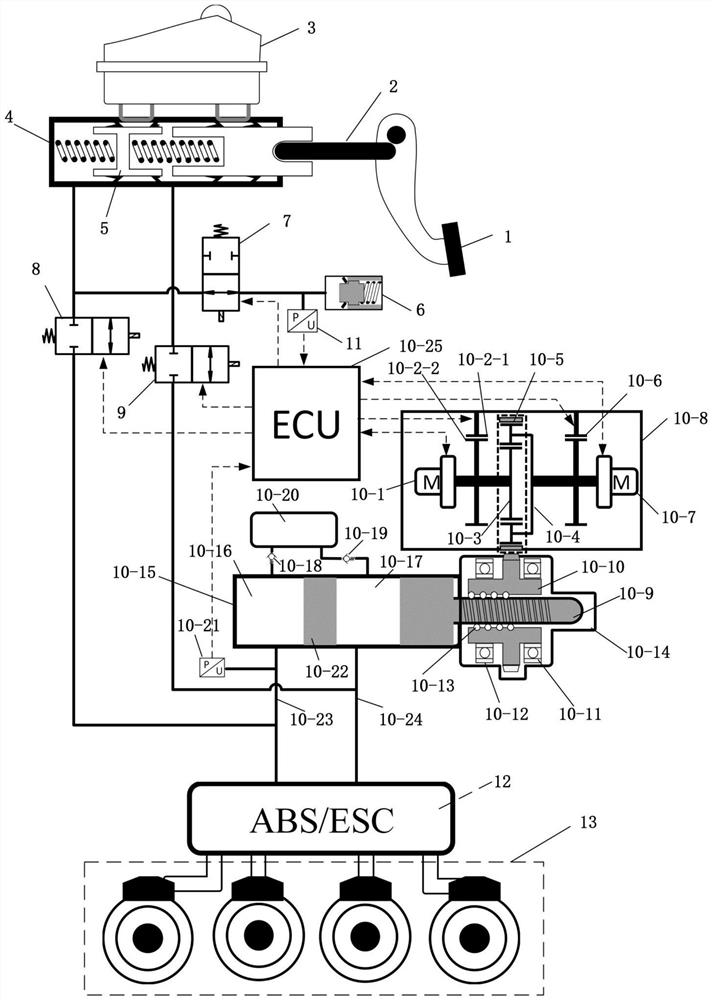

[0033] Example: The booster system of the present invention is mainly applied to the establishment of a high-pressure source of a vehicle-by-wire hydraulic brake system, but is not limited to other similar scenarios where pressure buildup of a liquid is required. In order to further illustrate the function of the present invention, the following combination image 3 A typical embodiment of the application of the present invention is introduced: the application in the vehicle brake-by-wire system.

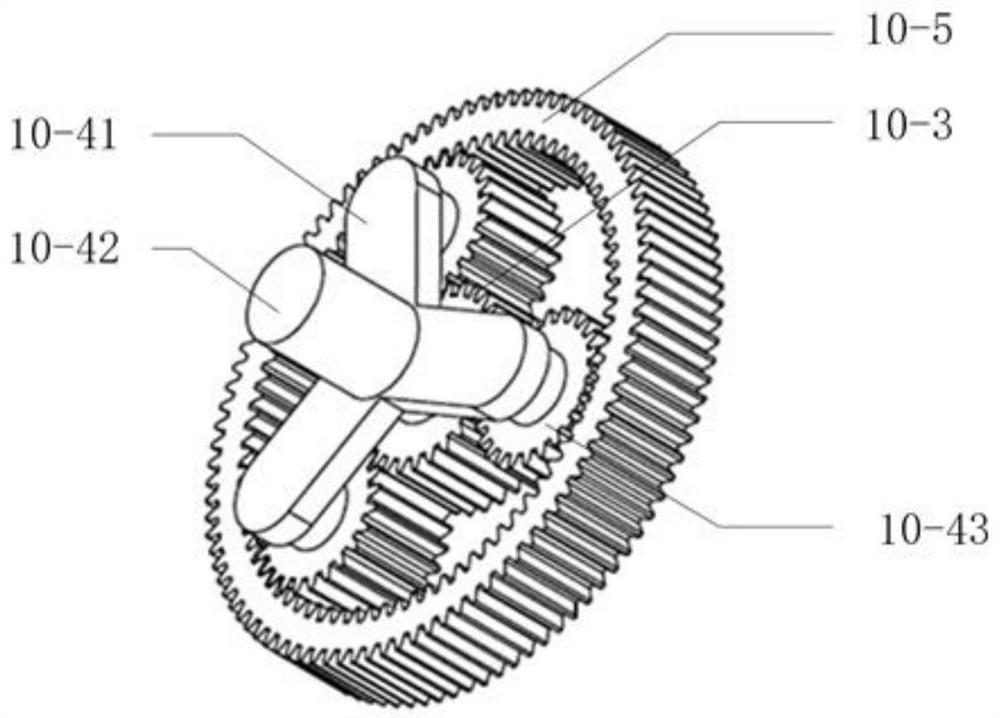

[0034] The brake-by-wire system with fail-operational capability proposed in this embodiment is a brake-by-wire system that requires a motor for active pressure build-up. Another motor system is backed up nearby, and the two can share the transmission mechanism of the original brake-by-wire system. When no fault occurs in the system, the first motor system is combined with the transmission mechanism, and the backup second motor system is combined with the housing through the lockin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com