Hand brake for railway wagon

A technology for railway wagons and brakes, which is applied to railway braking systems, operating mechanisms of railway vehicle brakes, railway car body parts, etc., and can solve the problems of increasing manufacturing difficulty and cost, occupying installation space, and output power not meeting heavy loads To meet the needs of the development of trucks and other issues, to achieve the effect of increasing the braking ratio, large chain output force, and meeting the development needs of heavy-duty technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The implementation of the present invention will be described in detail below in conjunction with the examples of implementation, but they do not constitute a limitation of the present invention, and are only examples. At the same time, the advantages of the present invention will become clearer and easier to understand.

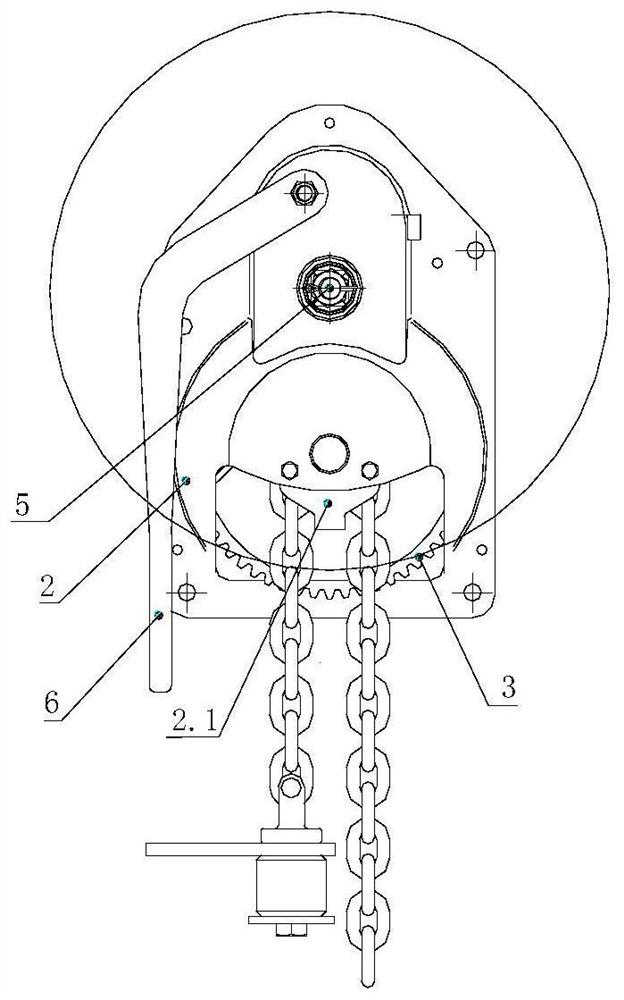

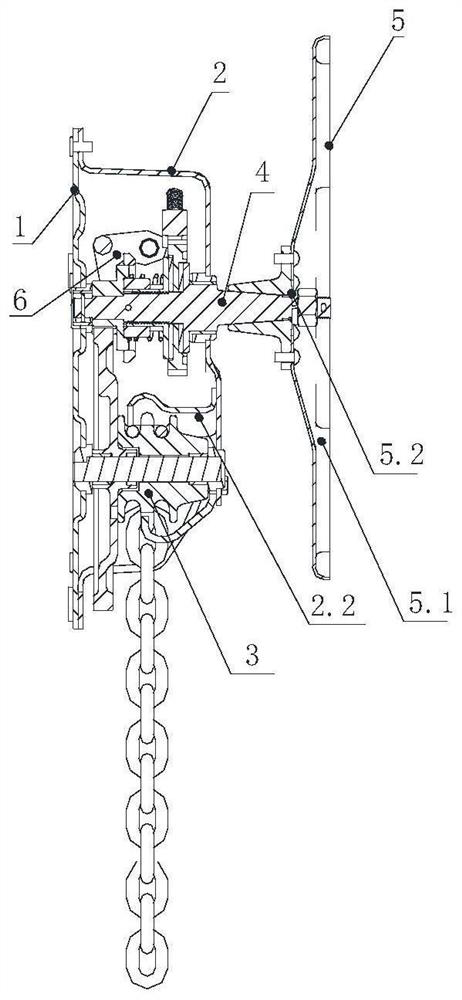

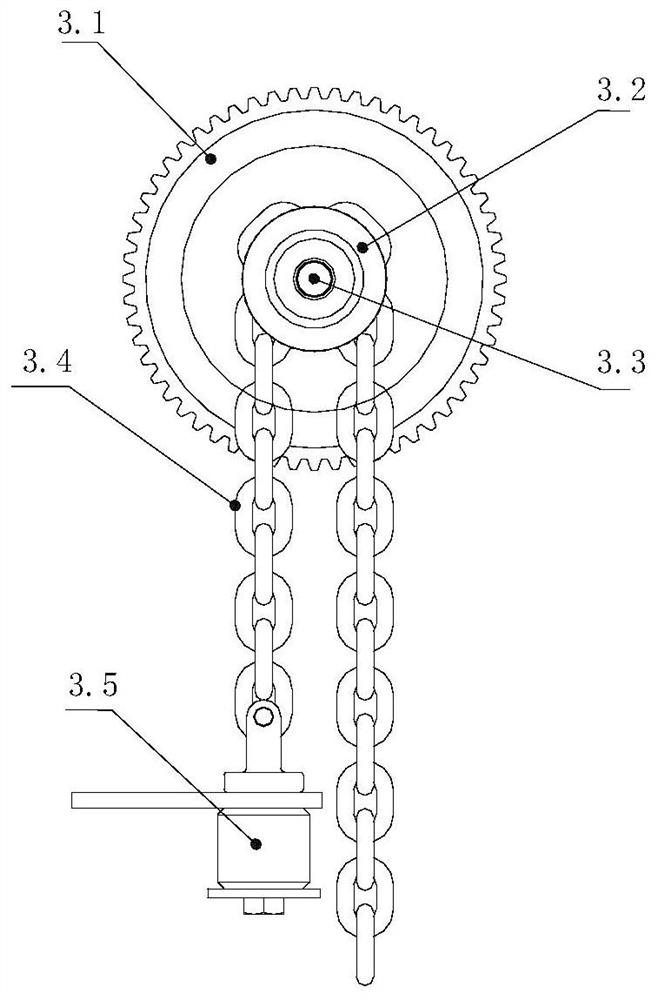

[0039] Such as Figure 1 ~ Figure 2 A hand brake for a railway freight car shown includes a base 1, a case cover 2, a winding wheel mechanism 3, a driving shaft mechanism 4, a handwheel mechanism 5 and a handle mechanism 6; the winding wheel mechanism 3 is arranged on the base 1 Below the accommodation chamber enclosed between the box cover 2, the winding chain wheel mechanism 3 is located at the lower end of the driving shaft 4.1, one end is installed on the base 1 through the bearing seat, and the other end is installed on the bearing seat of the box cover 2. The driving shaft mechanism 4 is arranged on the top of the rolling chain wheel mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com