Drilling tool and method for plug sweeping and milling of tie-back cylinder

A tie-back barrel and drilling tool technology, which is applied in the field of oil drilling, can solve the problems of affecting the running of milling shoes or tie-back tools, affecting the engineering timeliness, and low efficiency, achieving high work reliability and safety, and avoiding cumbersome procedures. , the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereby.

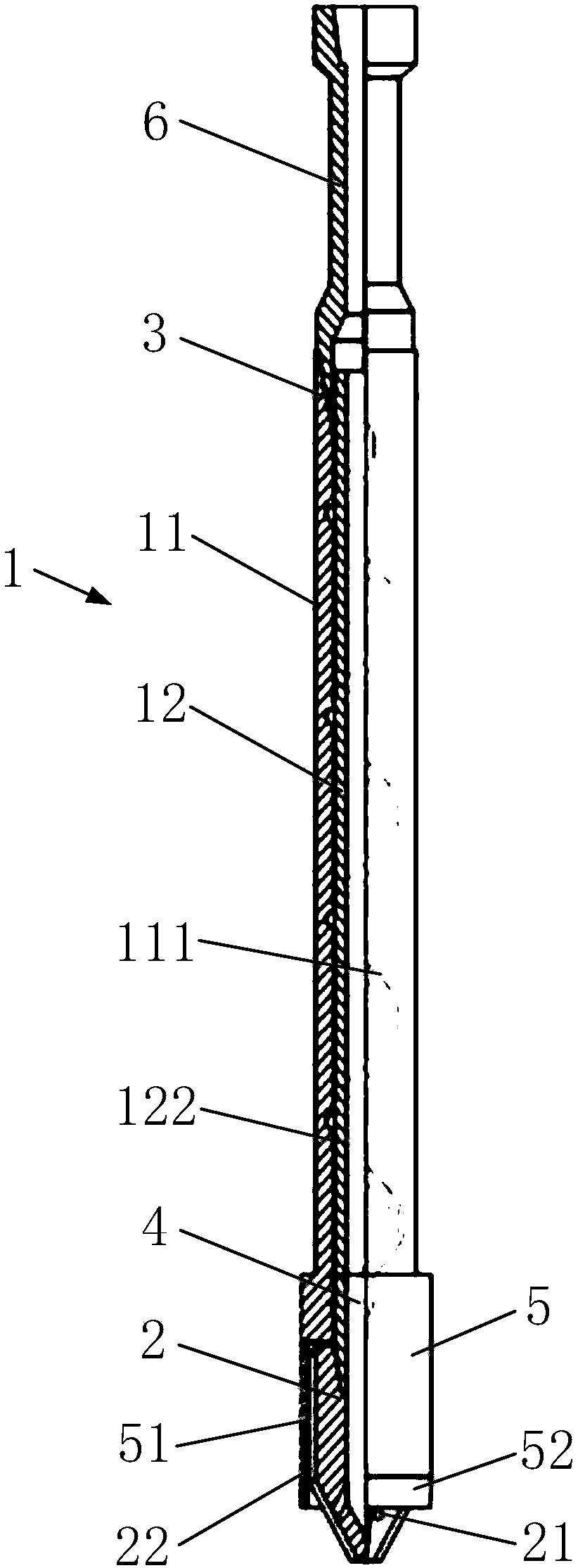

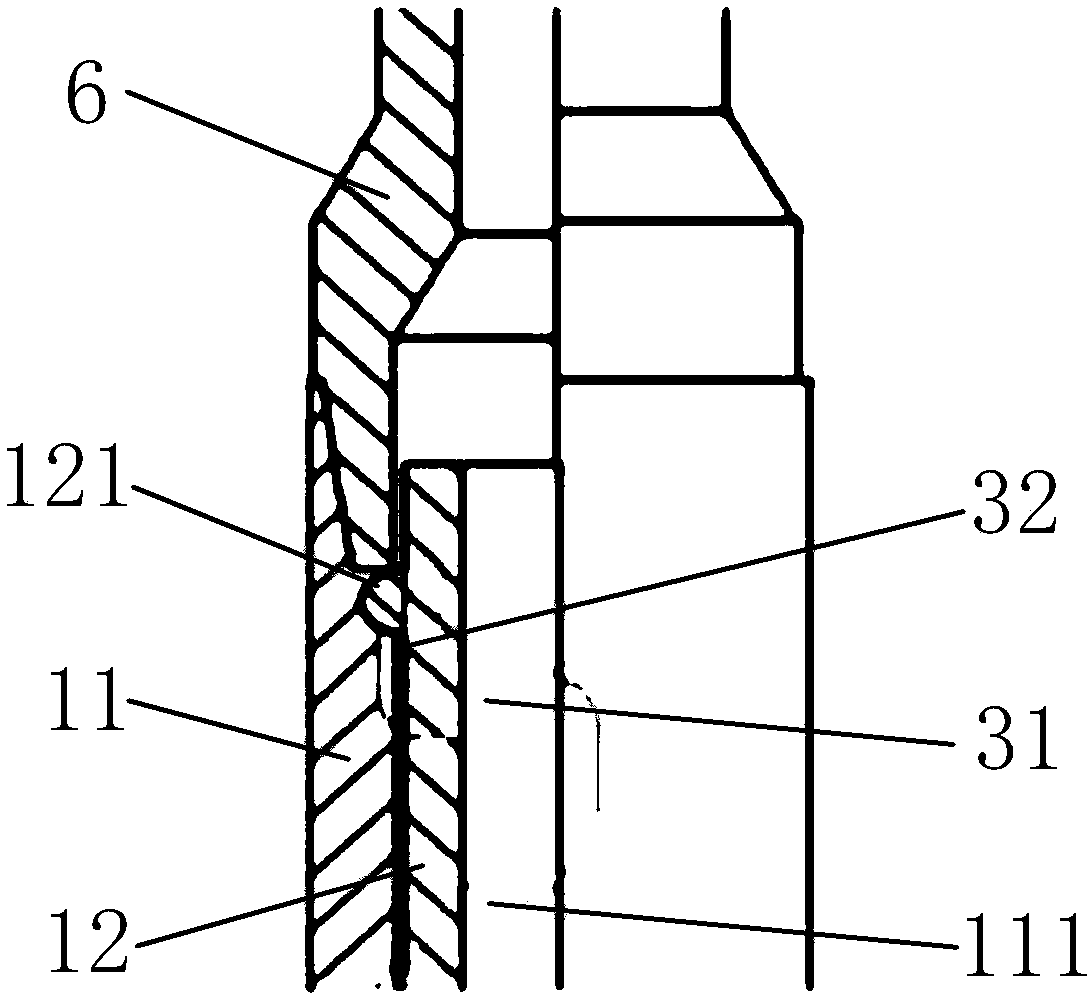

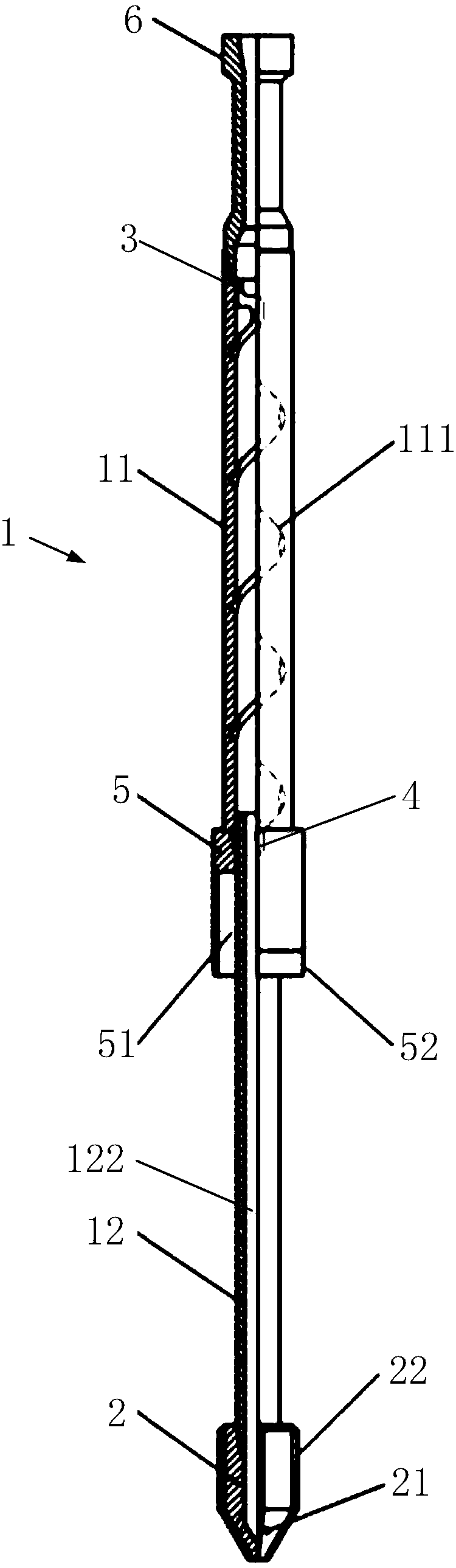

[0032] Such as Figure 1 to Figure 4 As shown, the drill tool used for plug cleaning and milling of the return barrel in this embodiment includes a drill rod, a telescopic rod assembly 1 and a milling shoe 2 connected in sequence. Among them, the drill rod is used to provide the driving force of the telescopic rod assembly 1 and the milling shoe 2; the milling shoe 2 is used to mill the inner wall of the return barrel; the telescopic rod assembly 1 includes a telescopic outer rod 11, a telescopic inner rod 12 and a stop components. Wherein, one end of the telescopic outer rod 11 is connected with the drill pipe through the upper joint 6, the other end of the telescopic outer rod 11 is sleeved outside the telescopic inner rod 12, and the end of the telescopic in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com