Securing element

A technology for fixing parts and components, applied in the direction of threaded fasteners, connecting members, connectors specially modified for tensile loads, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

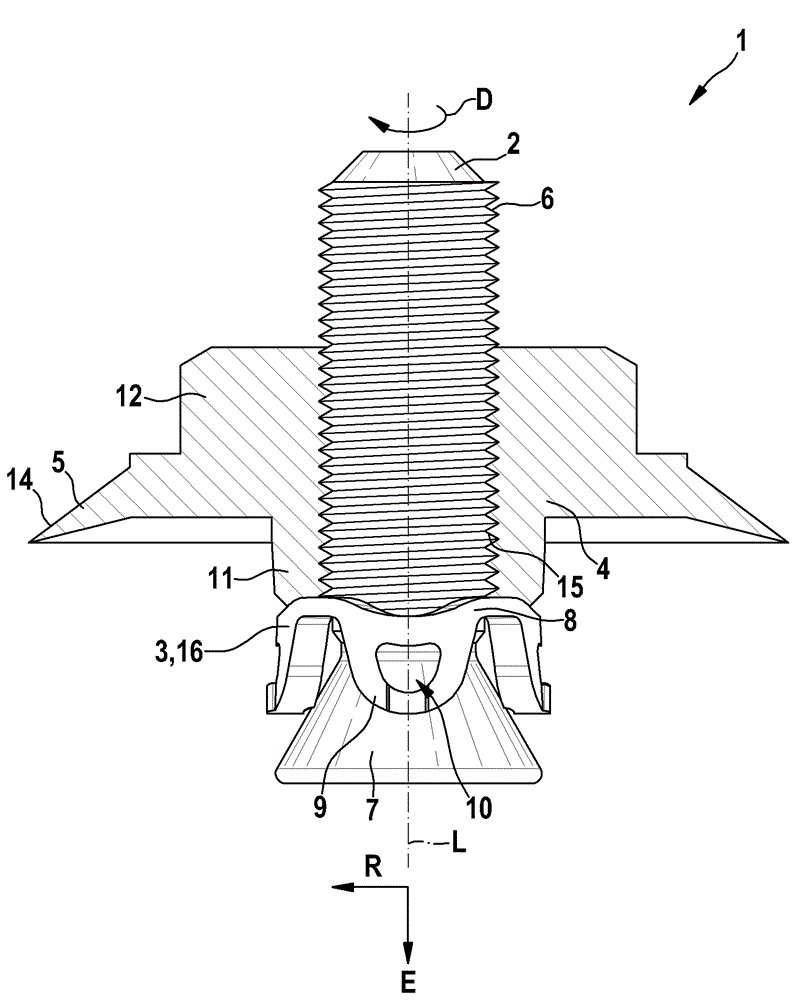

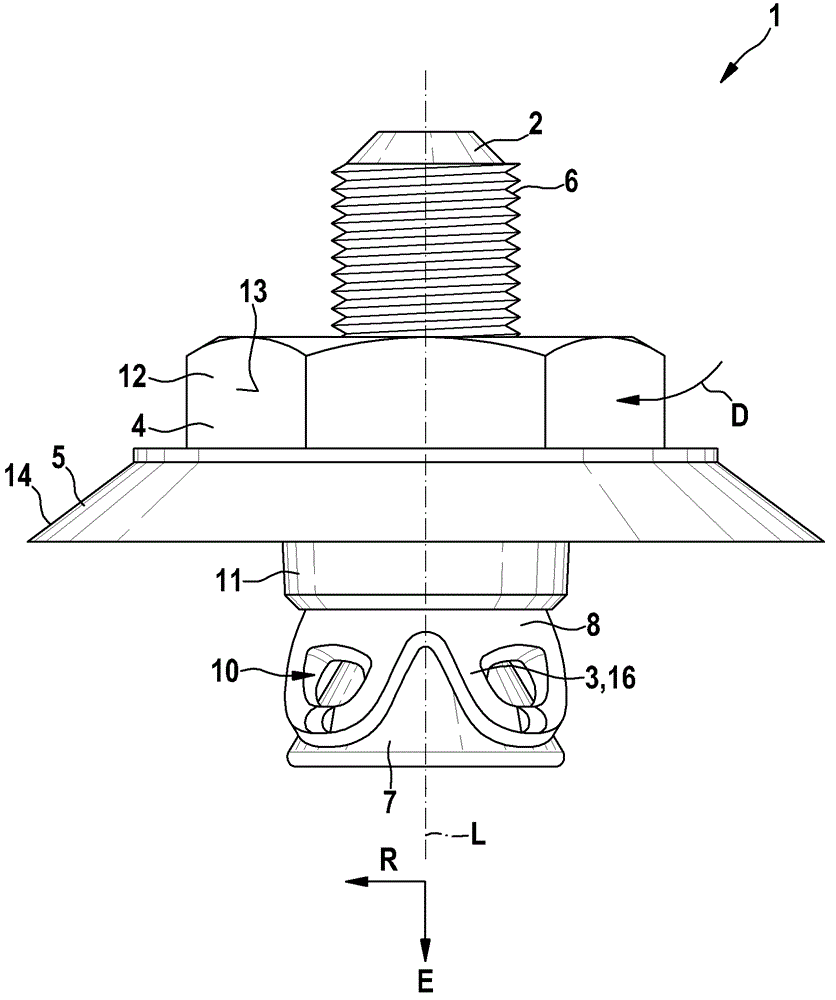

[0017] exist figure 1 and 2 A fastening element 1 according to the invention is shown in FIG. 1 for fastening components (not shown) on a fastening base (also not shown). The fixing part 1 consists of a shank 2, an expansion part 3 and a nut 4 on which a disc 5 is integrally formed.

[0018] The shank 2 is formed as a conical rod with a cylindrical section, which extends in the direction of the longitudinal axis L of the fastening part 1 and has an external thread 6 , to which an expansion body 7 adjoins forward in the insertion direction E. The expansion body 7 is shaped as a frusto-conical body, which increases in diameter in the direction of insertion E. The expansion part 3 is a sleeve 8 which forms a closed ring, on which a sheet-shaped expansion lug 9 is integrally arranged, the free end of which forms the front end of the expansion part 3 . The expansion lugs 9 are rounded at their front ends and each have an opening 10 which is arranged centrally in the surface of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com