A kind of preparation method of high-strength and low-static ctp plate backing paper

A low-static, paper-backed technology, applied in the field of papermaking, can solve the problems of poor moisture resistance and reduced tear resistance of the backing paper, and achieve high tear resistance, strong compactness and bonding ability, and simple and efficient preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

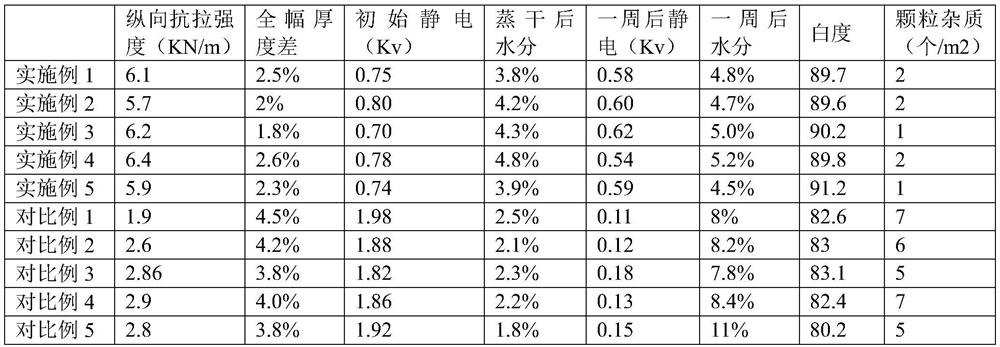

Examples

Embodiment 1

[0038] A preparation method of high-strength and low-static CTP plate backing paper, comprising the following preparation steps:

[0039] (1) Prepare slurry: mix and beat the raw material slurry and auxiliary agents to prepare a mixed slurry; the raw material slurry includes 30% bleached softwood pulp and 70% bleached hardwood pulp, and the pulp size is 35 ° SR, Wet weight 1.5g; additives and their dosages are: degassing agent, 0.5kg per ton of paper; cationic starch, 10kg per ton of paper;

[0040] (2) Pre-treatment of sizing: dehydrating the mixed slurry through the net part, pressing, and pre-drying to obtain raw paper;

[0041] (3) Sizing: enter the surface sizing treatment process, adopt aminocellulose-vermiculite modified styrene-acrylic emulsion to carry out surface sizing to the raw paper described in step (2), and obtain the paper sheet after surface sizing treatment ; The amount of paper per ton of aminocellulose-vermiculite modified styrene-acrylic emulsion is 18kg...

Embodiment 2

[0047] The difference from Example 1 is that a method for preparing a high-strength and low-static CTP plate backing paper includes the following preparation steps:

[0048] (1) Prepare slurry: mix and beat the raw material slurry and auxiliary agents to prepare a mixed slurry; the raw material slurry includes 20% bleached softwood pulp and 80% bleached hardwood pulp, and the pulp size is 38 ° SR, Wet weight 1.8g; additives and their dosages are: degassing agent, 0.6kg per ton of paper; cationic starch, 11kg per ton of paper;

[0049] (2) Pre-treatment of sizing: dehydrating the mixed slurry through the net part, pressing, and pre-drying to obtain raw paper;

[0050] (3) Sizing: enter the surface sizing treatment process, adopt aminocellulose-vermiculite modified styrene-acrylic emulsion to carry out surface sizing to the raw paper described in step (2), and obtain the paper sheet after surface sizing treatment ; The amount of paper per ton of aminocellulose-vermiculite modif...

Embodiment 3

[0056] The difference from Example 1 is that a method for preparing a high-strength and low-static CTP plate backing paper includes the following preparation steps:

[0057] (1) Prepare slurry: mix and beat the raw material slurry and auxiliary agents to form a mixed slurry; the raw material slurry includes 15% bleached softwood pulp and 85% bleached hardwood pulp, and the pulp size is 42 ° SR, Wet weight 2.0g; additives and their dosages are: degassing agent, 0.8kg per ton of paper; cationic starch, 13kg per ton of paper;

[0058] (2) Pre-treatment of sizing: dehydrating the mixed slurry through the net part, pressing, and pre-drying to obtain raw paper;

[0059] (3) Sizing: enter the surface sizing treatment process, adopt aminocellulose-vermiculite modified styrene-acrylic emulsion to carry out surface sizing to the raw paper described in step (2), and obtain the paper sheet after surface sizing treatment ; The amount of paper per ton of aminocellulose-vermiculite modified...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com