A planar target unbinding device and method

A planar target and unbundling technology, which is applied in metal material coating process, vacuum evaporation plating, coating, etc., can solve the problems of multi-indium solder and difficult separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

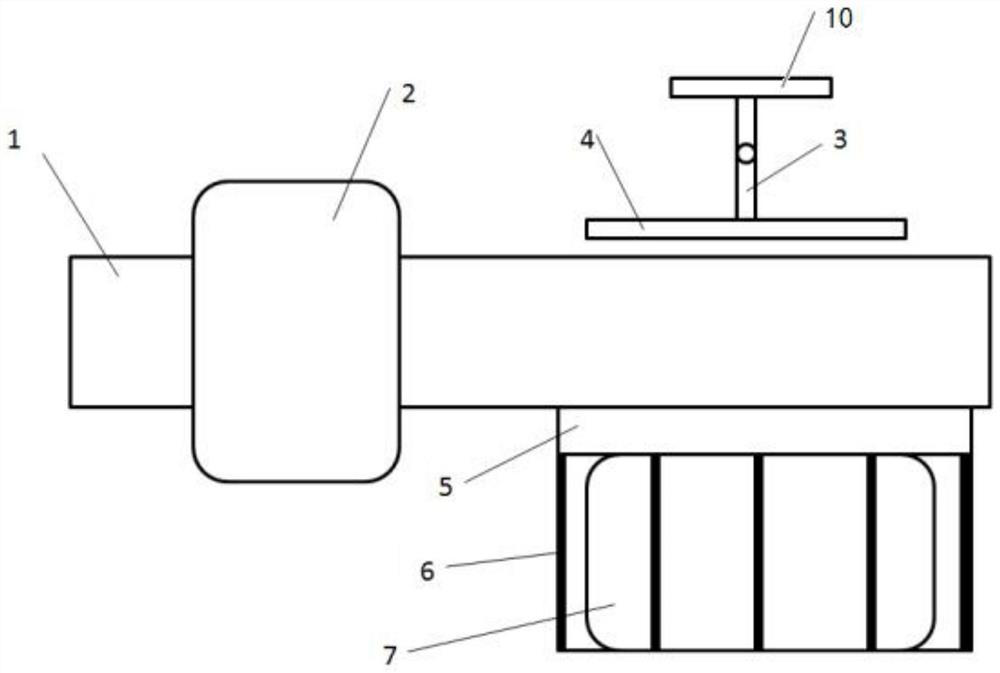

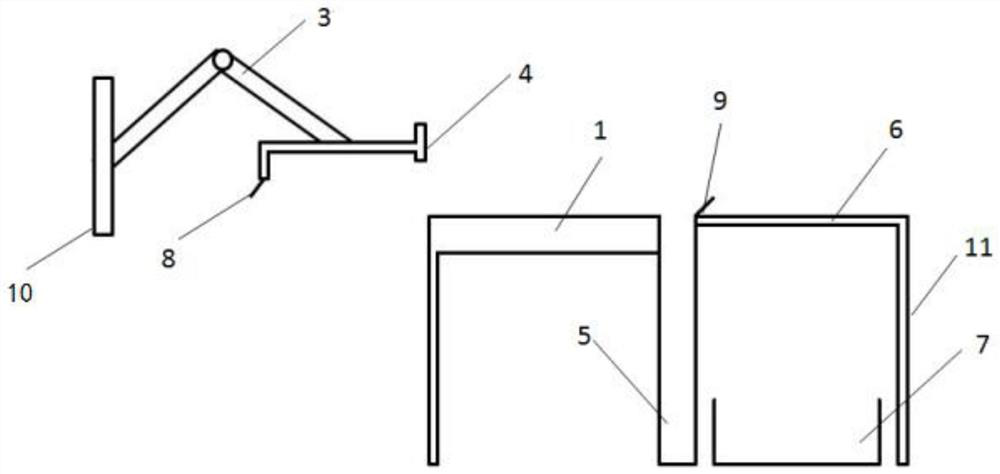

[0066] Unbinding the planar target by using the planar target unbinding device provided by the present invention includes the following steps:

[0067] (a) Planar target washing: wipe off the dust on the surface of the planar target with a clean cloth, then put the planar target into an ultrasonic cleaning machine, ultrasonically wash it with deionized water for 25 minutes, take it out and dry it for use; wherein, the The planar target material includes a waste target, an indium solder layer and a copper back plate that are stacked in sequence, and several copper wires are arranged in the indium solder layer;

[0068] (b) Removing the backsplash film: use a sandblasting gun to perform sandblasting on the position of the backsplash film in the cleaned planar target to remove the backsplash film and obtain a pretreated target:

[0069] (c) Infrared heating melting indium: put the pretreatment target on the conveying device 1, and the copper back plate is in contact with the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com