Liquefaction unit in vehicle-mounted mobile oilfield vent gas recovery system and liquefaction method thereof

A recovery system and air release technology, which is applied in the recovery of liquid hydrocarbon mixtures and the petroleum industry, can solve problems such as instability, waste of resources, and poor economy, and achieve the effects of reducing height, reducing emissions, and improving product recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0025] Example.

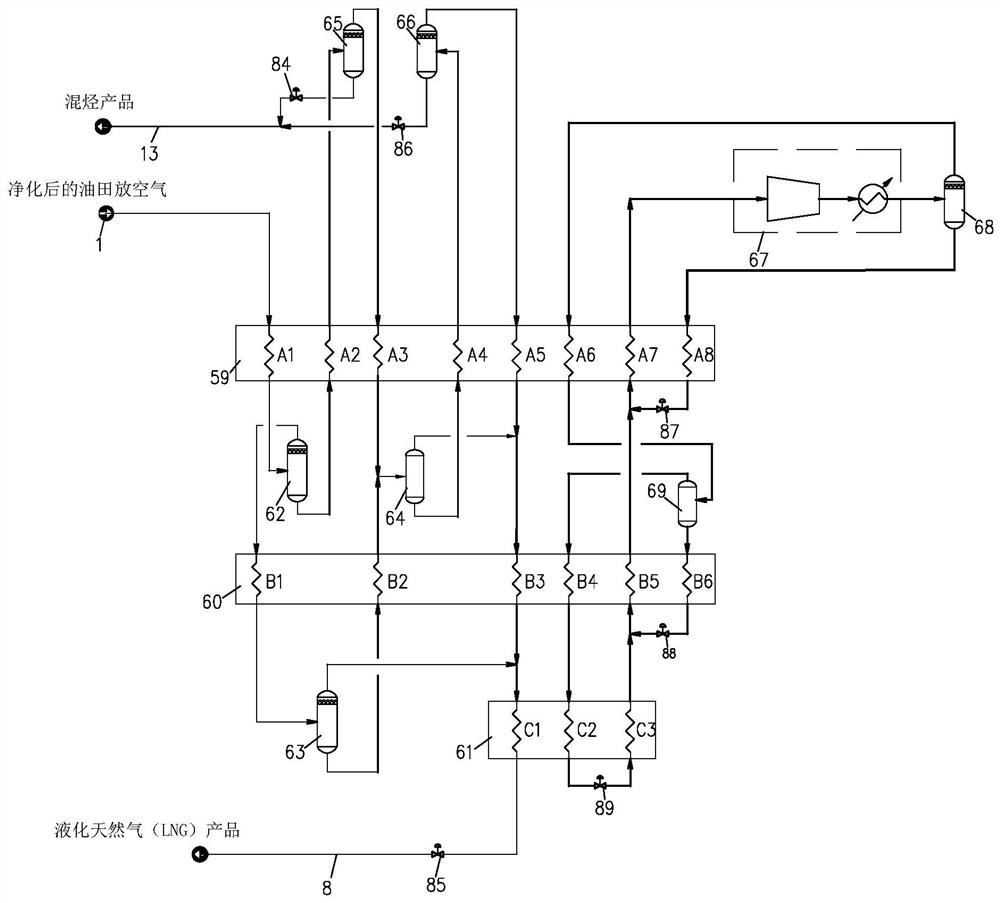

[0026] see figure 1 , figure 1Shown is the liquefaction unit in the vehicle-mounted mobile oilfield release air recovery system. The vehicle-mounted mobile oil field release air recovery system is used to recover mixed hydrocarbons and liquefied natural gas products, including two units: a purification unit and a liquefaction unit.

[0027] The liquefaction unit in this embodiment includes a precooling heat exchanger 59, a cryogenic heat exchanger 60, a liquefaction heat exchanger 61, a primary separator 62, a secondary separator 63, a tertiary separator 64, a normal temperature separator 65, a mixing Hydrocarbon separator 66 and closed mixed refrigerant three-stage throttling refrigeration devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com