Clamping device for thin plate compression experiment

A clamping device and experimental technology, applied in the direction of workpiece clamping devices, manufacturing tools, etc., can solve the problem that the cyclic loading of thin plate tension-compression cannot be realized, continuous tension-compression experiments of thin plates cannot be carried out, and large deformation cannot be carried out Compression and other issues, to achieve the effect of good promotion and use value, convenient strain collection, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

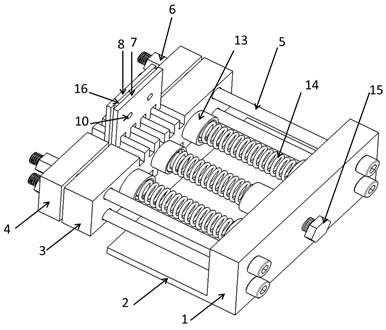

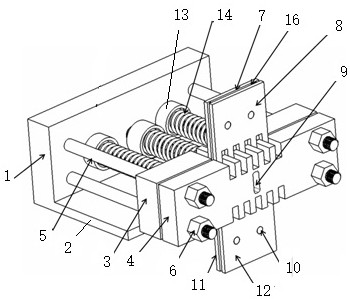

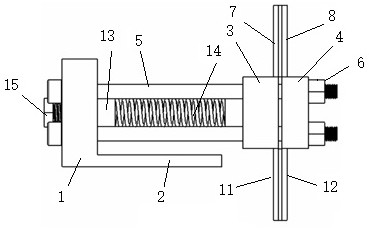

[0024] The present invention consists of clamping support plate 1, bottom plate 2, rear sample splint 3, front sample splint 4, screw rod 5, nut 6, rear upper groove splint 7, front upper groove splint 8, strain measurement hole 9, screw Column 10, rear lower grooved splint 11, front lower grooved splint 12, spring seat 13, spring 14, spring bolt 15 form.

[0025] Figure 1-5 It is shown that the clamping support plate 1 and the base plate 2 form an L-shaped structure, the clamping support plate 1 is placed vertically, the base plate 2 is in a horizontal position, and the base plate 2 is connected to the lower end of the clamping support plate 1 .

[0026] Figure 1-5 It shows that the front sample splint 4 and the rear sample splint 3 are respectively the same rectangular plate, the front sample splint 4 and the rear sample splint 3 are parallel and opposite, and the sample 16 is placed on the front sample splint 4 and the rear sample splint 3 between. The rear sample spli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com