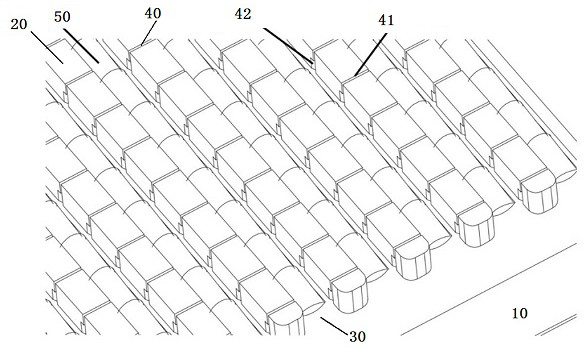

A bipolar plate for a squamous split fuel cell with capillary ridges

A fuel cell and bipolar plate technology, applied in the direction of fuel cells, fuel cell parts, circuits, etc., can solve the problems of low water carrying capacity and water discharge efficiency of fuel cells, affecting the overall performance of fuel cells, etc., to achieve improved cooling Effects of starting performance, improving gas mass transfer performance, and improving drainage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method of preparing a bipolar plate for the fuel cell of the present invention includes the following steps:

[0038] Step 1, using a graphite sheet having a thickness of 1.5 mm as a substrate;

[0039] Step 2, the bipolar plate flow field is designed with parallel flow channels, the flow path width is 0.6mm, the flow channel groove is 0.8mm, and the flow channel groove is 0.6mm;

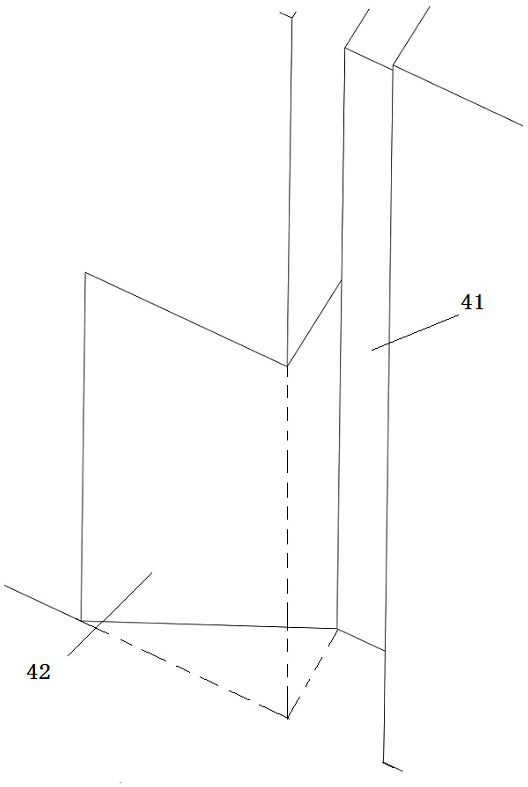

[0040] Step 3, the capillary design is specifically as follows: 1 The upper rectangle groove of the capillary is on three sides of the flow path ridge, the groove width is 0.05mm, the groove depth is 0.1mm, and the first rectangular groove is 0.4mm from the top of the ridge; 2 The upper right angle triangular tank in the crates is on both sides of the flow path ridge, and the two right angle sides of the right angle triangle are 0.1 mm and 0.05 mm, respectively, and the groove is 0.3mm;

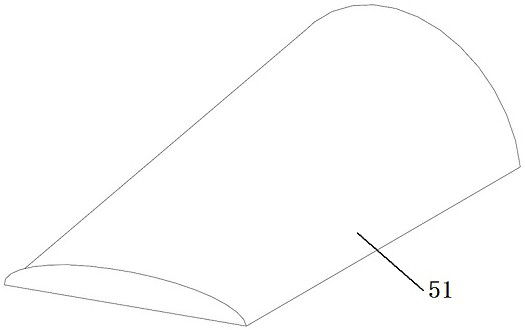

[0041] Step 4, the squamous ridge design is as follows: 1 Squam length is 1 mm, the width is 0.6mm, the hei...

Embodiment 2

[0044] Step 1, using a graphite sheet having a thickness of 1.5 mm as a substrate;

[0045] Step 2, the bipolar plate flow field is designed with parallel flow channels, the flow path width is 0.6mm, the flow channel groove is 0.8mm, and the flow channel groove is 0.6mm;

[0046] Step 3, the capillary ridge design is as follows: 1 The rectangular groove of the capillary spine is on three sides of the flow path ridge, the groove width is 0.06mm, the groove depth is 0.5mm away from the top of the ridge distance of the first rectangular groove; 2 Cartestrointegrade triangle tanks in the bottom of the ridges On the two sides of the flow path ridge, the two right angle sides of the right angle triangle are 0.15 mm and 0.06mm, respectively, the groove depth is 0.2mm;

[0047] Step 4, the squamous ridge design is as follows: 1 Squam length is 1.5mm, the width is 0.6mm, the height of the squamous ridge is 0.25mm, the height of the squamous ridge is 0.055mm, from low to high The slope is 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com