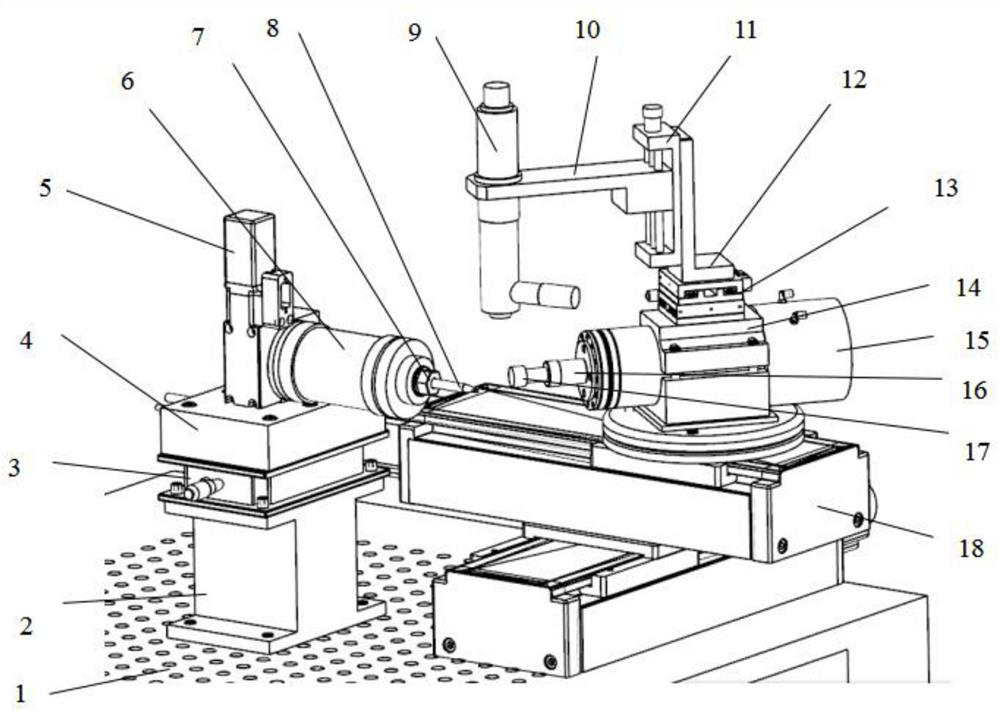

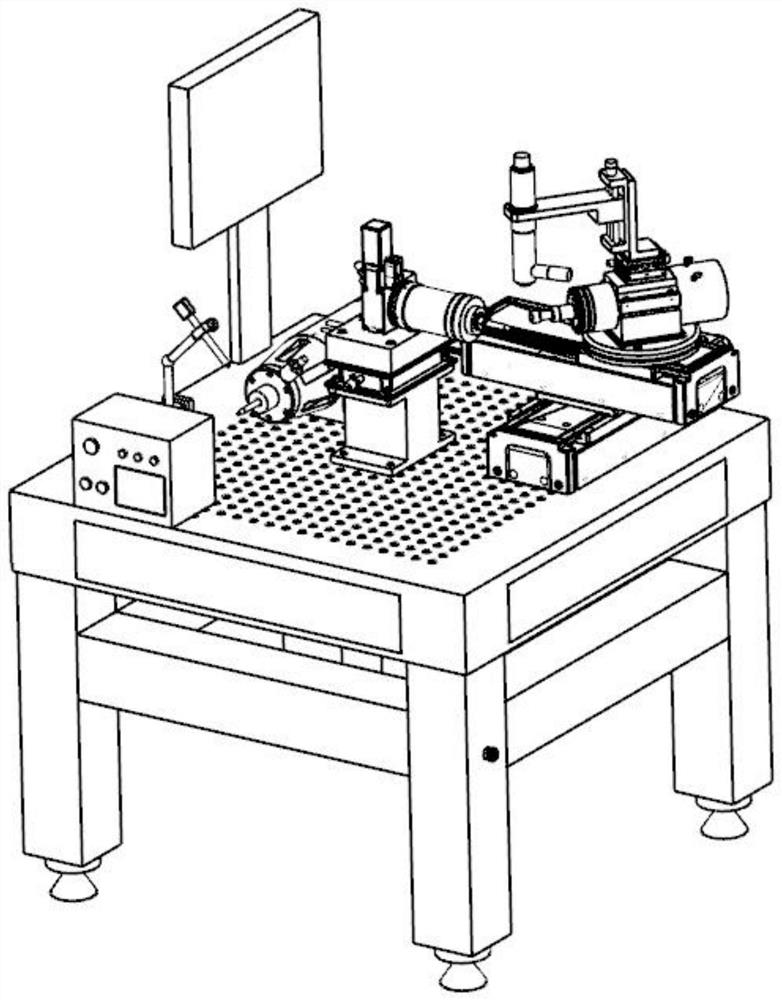

A dynamic balance test and correction system for diamond micro-diameter milling cutter

A diamond and balance detection technology, which is applied in the field of tool manufacturing, can solve the problems of reduced precision and achieve the effects of improving dynamic balance precision, processing quality and dynamic characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0048] The present embodiment carries out the dynamic balance test and correction of the diamond micro-diameter milling cutter according to the following steps:

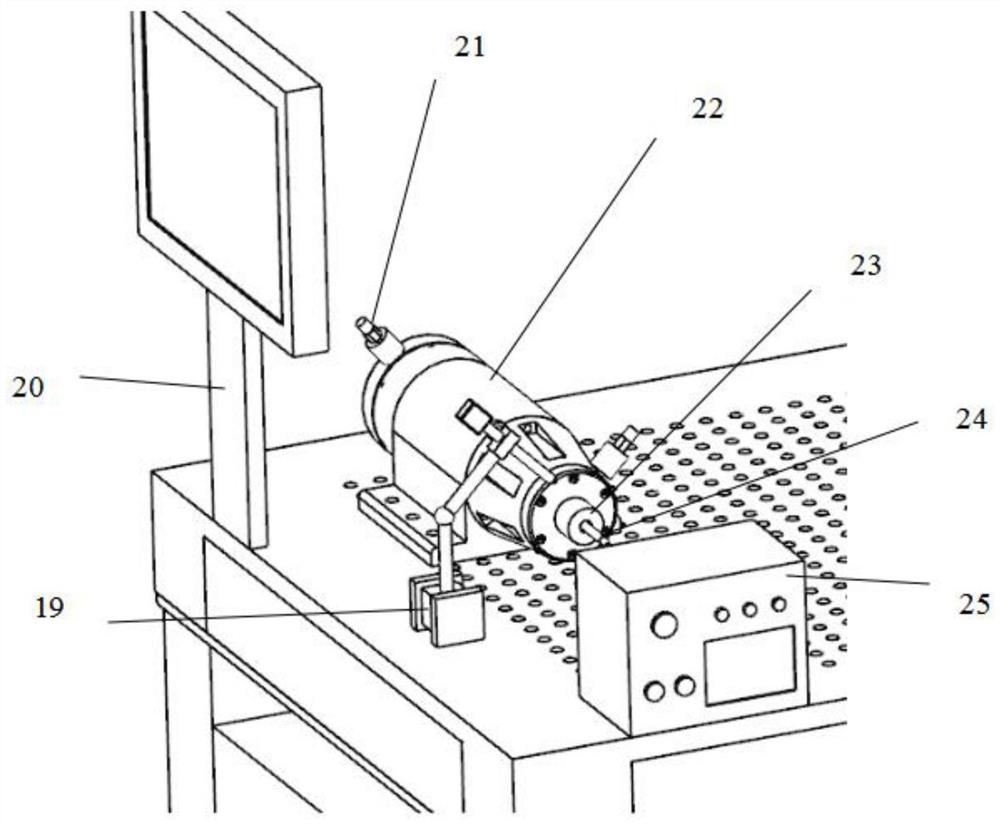

[0049] Step 1: Install the tool shank of the diamond micro-milling cutter 24 to be dynamically balanced on the pneumatic chuck B23, fix the two vibration sensors 21 on the two planes of the dynamic balance spindle 22 by magnetic attraction, and install the photoelectric The sensor 19 is magnetically mounted on the precision air-floating vibration isolation platform 1, and the probe is aligned with the fluorescent sticker on the pneumatic chuck B23.

[0050] Step 2: Start the dynamic balance spindle 22, and detect the dynamic balance state of the diamond micro-milling cutter 24 to be dynamically balanced under the working condition of the dynamic balance spindle 22 at 10,000 rpm, and obtain an unbalanced mass size of 28 mg and a phase of 10 from the reference phase. °And mark the position of the unbalanced mass on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com